Manifold anti-deformation welding process

A welding process and anti-deformation technology, applied in welding equipment, manufacturing tools, metal processing, etc., can solve the problems of condensation and bending deformation of the manifold, high labor intensity, and large deformation of the manifold, so as to ensure welding quality and improve production. Efficiency, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

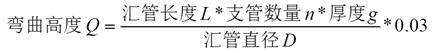

[0022] The manifold anti-deformation welding process includes the following steps:

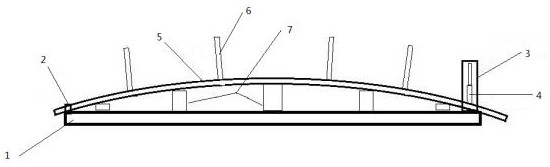

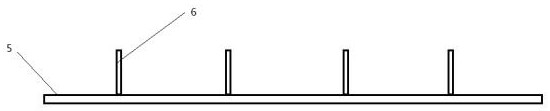

[0023] (1) Prepare the mold: Take two steel pipes 1 of the same size and weld them side by side, and weld two rectangular blocks 2 symmetrically on the edge of one end of the steel pipes as the fixed end of the manifold. The distance between the two rectangular blocks is slightly larger than that of the manifold The outer diameter of the pipe; the other end of the steel pipe is welded with a fixed bracket 3 as the header control end;

[0024] (2) Manifold deformation: put the manifold 5 to be welded on the mold, where one end of the manifold is welded together with the two rectangular blocks 2 at the fixed end, and the other end of the manifold passes through the fixed bracket 3 at the control end, Then the jack 4 is placed between the header pipe 5 and the fixed bracket 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com