Washable slow-rebound polyurethane foam, and production method and application thereof

A technology of polyurethane foam and slow rebound, which is applied in the field of polyurethane foam, which can solve the problems of long-term non-drying, peculiar smell, long mites, etc., and achieve the effects of slow rebound speed, resource saving and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

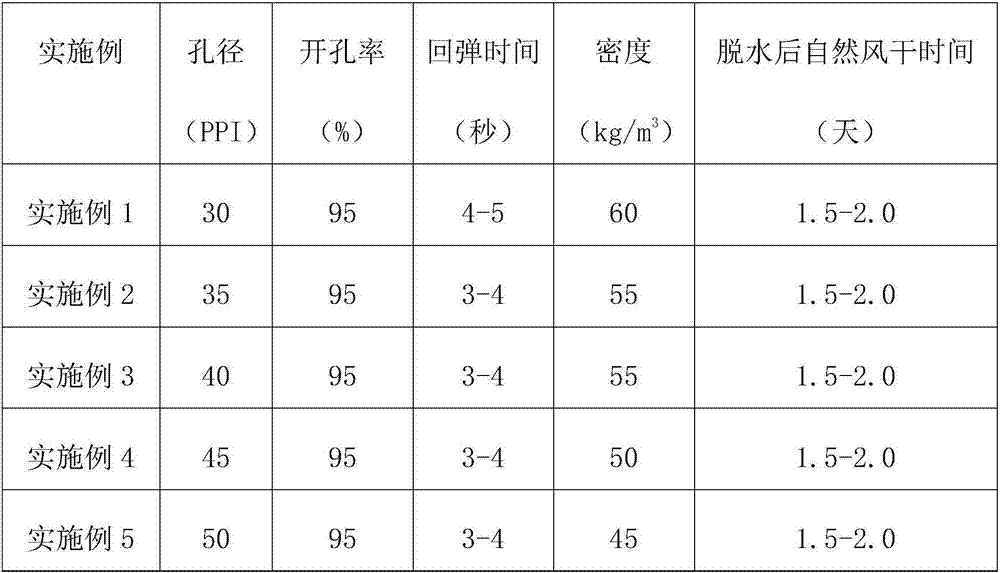

Examples

preparation example Construction

[0033] A preparation method of washable slow rebound polyurethane foam, comprising:

[0034] Material preparation step: take each raw material according to the formula ratio, and set aside;

[0035] Reaction steps: put the polyether polyol, isocyanate, stabilizer and catalyst in the formula amount into a reaction container for reaction, reaction conditions: normal temperature, normal pressure, high-speed stirring and mixing; obtain polyurethane foam material;

[0036] The basic chemical reaction formula is as formula 1:

[0037] R'-OH+R-NCO→R'-NCO-R Formula 1;

[0038] Wherein, R'-OH: polyether polyol; R-NCO: isocyanate; R'-NCO-R: polyurethane;

[0039] The step of removing the film and opening the pores: put the polyurethane foam material into a safe and airtight container filled with combustible gas. After igniting the combustible gas, it will generate an instant high temperature and explode, so as to remove the film and open the pores of the polyurethane foam material; ge...

Embodiment 1

[0044] A washable slow rebound polyurethane foam, prepared from the following raw materials: polyether polyol, isocyanate, stabilizer and catalyst, the weight ratio of polyether polyol, isocyanate, stabilizer and catalyst is 100:46 : 0.3: 0.3, wherein the catalyst comprises triethylenediamine (A33) and stannous octoate (T-9), and the weight ratio of triethylenediamine (A33) and stannous octoate (T-9) is 0.2: 0.1.

[0045] A preparation method of washable slow rebound polyurethane foam, comprising:

[0046] Material preparation step: take each raw material according to the formula ratio, and set aside;

[0047] Reaction steps: put the polyether polyol, isocyanate, stabilizer and catalyst in the formula amount into a reaction container for reaction, reaction conditions: normal temperature, normal pressure, high-speed stirring and mixing; obtain polyurethane foam material;

[0048] The step of removing the film and opening the pores: put the polyurethane foam material into a sa...

Embodiment 2

[0050] A washable slow rebound polyurethane foam, prepared from the following raw materials: polyether polyol, isocyanate, stabilizer and catalyst, the weight ratio of polyether polyol, isocyanate, stabilizer and catalyst is 100:43 : 0.4: 0.35, wherein the catalyst comprises triethylenediamine (A33) and stannous octoate (T-9), and the weight ratio of triethylenediamine (A33) and stannous octoate (T-9) is 0.2: 0.15.

[0051] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com