Combed cotton and modified polyamide fabric and production process thereof

A production process, the technology of combed cotton, applied in the field of spinning, can solve the problems of affecting the wearing experience, lengthening, and easy deformation of 100% combed cotton, and achieve the effect of smooth hand feeling, smooth surface and full and delicate knitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

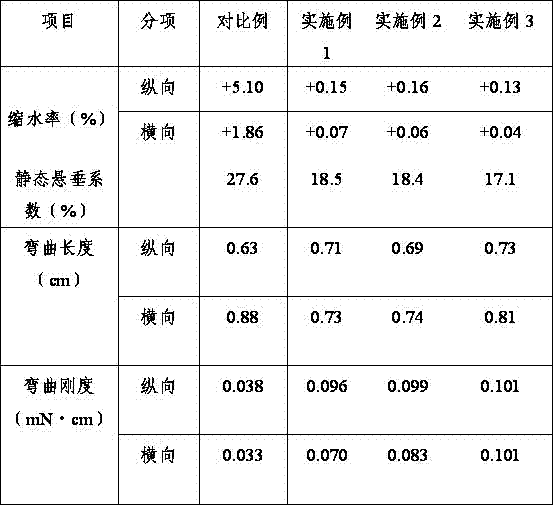

Examples

Embodiment 1

[0033] Select 90 parts of nylon chips and 10 parts of open-ended masterbatch, put them into the screw extruder at the same time after drying, the screw extruder is equipped with five temperature control zones, the temperature of the first zone is controlled at 240 °C, and the temperature of the second zone is controlled at 240 °C. The temperature in the third zone is controlled at 235°C, the temperature in the fourth zone is controlled at 250°C, and the temperature in the fifth zone is controlled at 255°C. After extrusion, it is spun through the spinning assembly, cooled and formed by the blowing device on both sides, and the spinning speed is controlled at 4000m / min, the blowing temperature is set at 22°C, the humidity is controlled at 65%, and the wind speed is controlled at 0.33m / s. The cooled and formed tow is oiled through the oiling device, and after passing through the spinning tunnel, it acts on the winding machine. Winding down to obtain POY, POY is sequentially passed...

Embodiment 2

[0035]Select 95 parts of nylon slices and 5 parts of open-ended masterbatch, put them into the screw extruder at the same time after drying, the screw extruder is equipped with five temperature control zones, the temperature of the first zone is controlled at 245 °C, and the temperature of the second zone is controlled at 245 °C. The temperature in the third zone is controlled at 240°C, the temperature in the fourth zone is controlled at 255°C, and the temperature in the fifth zone is controlled at 260°C. After extrusion, it is spun through the spinning assembly, cooled and formed by the blowing device on both sides, and the spinning speed is controlled at 4000m / min, the blowing temperature is set at 22°C, the humidity is controlled at 65%, and the wind speed is controlled at 0.33m / s. The cooled and formed tow is oiled through the oiling device, and after passing through the spinning tunnel, it acts on the winding machine. Winding down to obtain POY, the POY is sequentially pas...

Embodiment 3

[0037] Select 99 parts of nylon slices and 1 part of open-ended masterbatch, put them into the screw extruder at the same time after drying, the screw extruder is equipped with five temperature control zones, the temperature of the first zone is controlled at 250°C, and the temperature of the second zone is controlled at 250°C. The temperature in the third zone is controlled at 245°C, the temperature in the fourth zone is controlled at 260°C, and the temperature in the fifth zone is controlled at 265°C. After extrusion, it is spun through the spinning assembly, cooled and formed by the blowing device on both sides, and the spinning speed is controlled at 4000m / min, the blowing temperature is set at 22°C, the humidity is controlled at 65%, and the wind speed is controlled at 0.33m / s. The cooled and formed tow is oiled through the oiling device, and after passing through the spinning tunnel, it acts on the winding machine. Winding down to obtain POY, the POY is sequentially passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com