Hydraulic jet casing descaling device and process method for applying hydraulic jet casing descaling device

A hydraulic jetting and casing technology, which is applied in the direction of earthwork drilling, cleaning equipment, wellbore/well components, etc., can solve the problems of affecting liquid output, high operating cost, and slow descaling speed, etc., so as to improve the seepage channel , good descaling effect and thorough descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

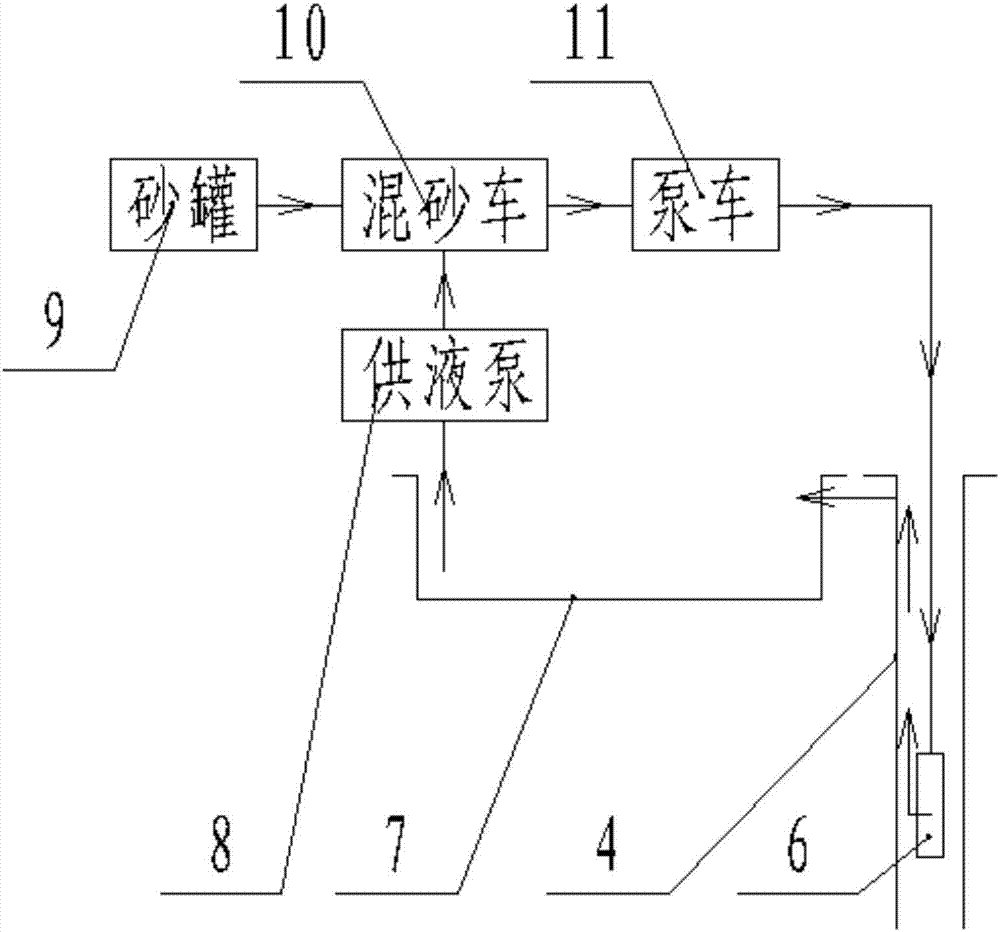

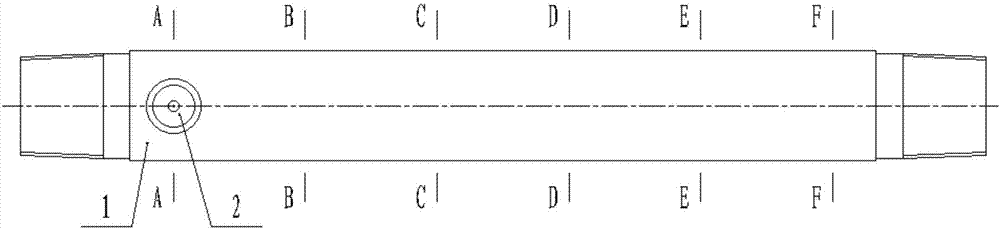

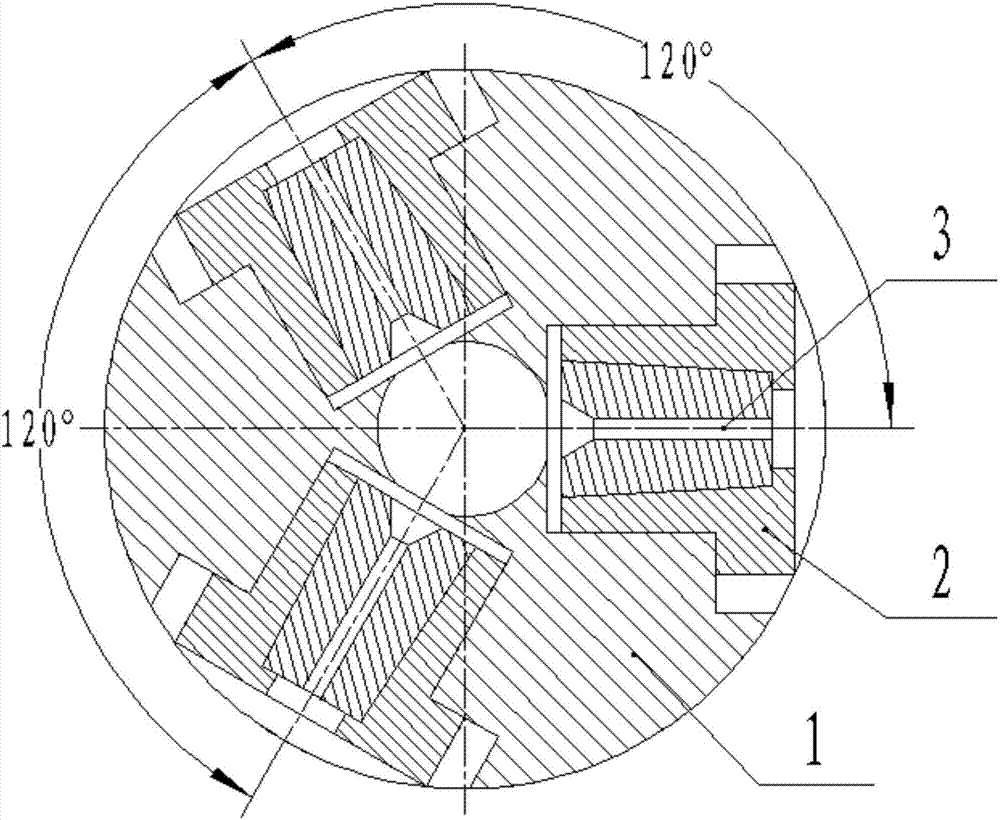

[0026] like figure 1 As shown, the present embodiment includes a sand tank 9, a sand mixing vehicle 10, a pump truck 11, a liquid supply pump 8, a pool 7 and a spray gun, and the liquid supply pump 8 transports the water in the pool 7 to the sand mixing vehicle 10, and the sand mixing The truck 10 mixes the quartz sand and water from the sand tank 9 and transports it to the pump truck 11. The spray gun goes down the well through the oil pipe, and the pump truck 11 pressurizes the water mixed with the quartz sand to the spray gun through the oil pipe. The water is sprayed out through the nozzle 2 on the spray gun to form a high-speed jet 5, thereby crushing the scale on the well wall to separate it from the casing wall, and the water sprayed from the nozzle 2 overflows from the well head and flows back into the pool 7. The spray gun It is connected in series in the descalin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com