Bubbling vaporizer

A vaporizer and bubbling technology, which is applied in combustion methods, liquid fuel supply/distribution, etc., can solve the problems of low calorific value, low operating efficiency, poor operating safety, etc., achieve pipe diameter reduction, improve operating efficiency, and operate The effect of safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

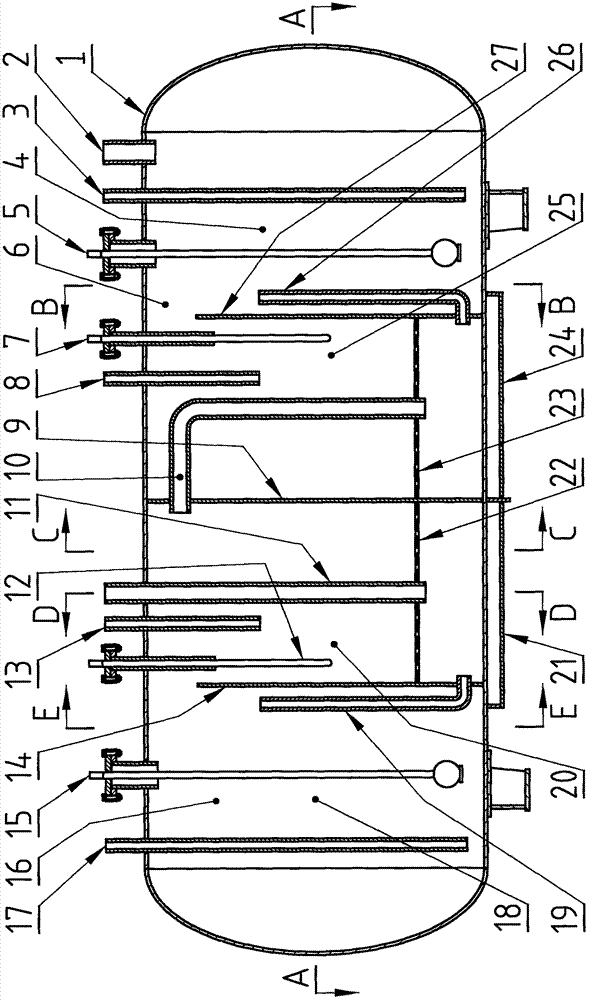

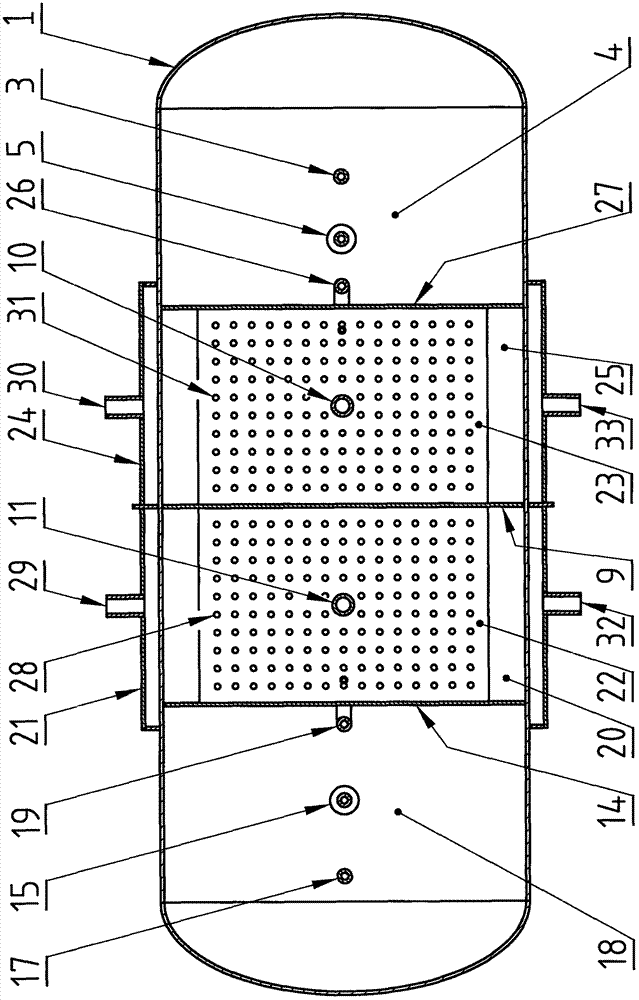

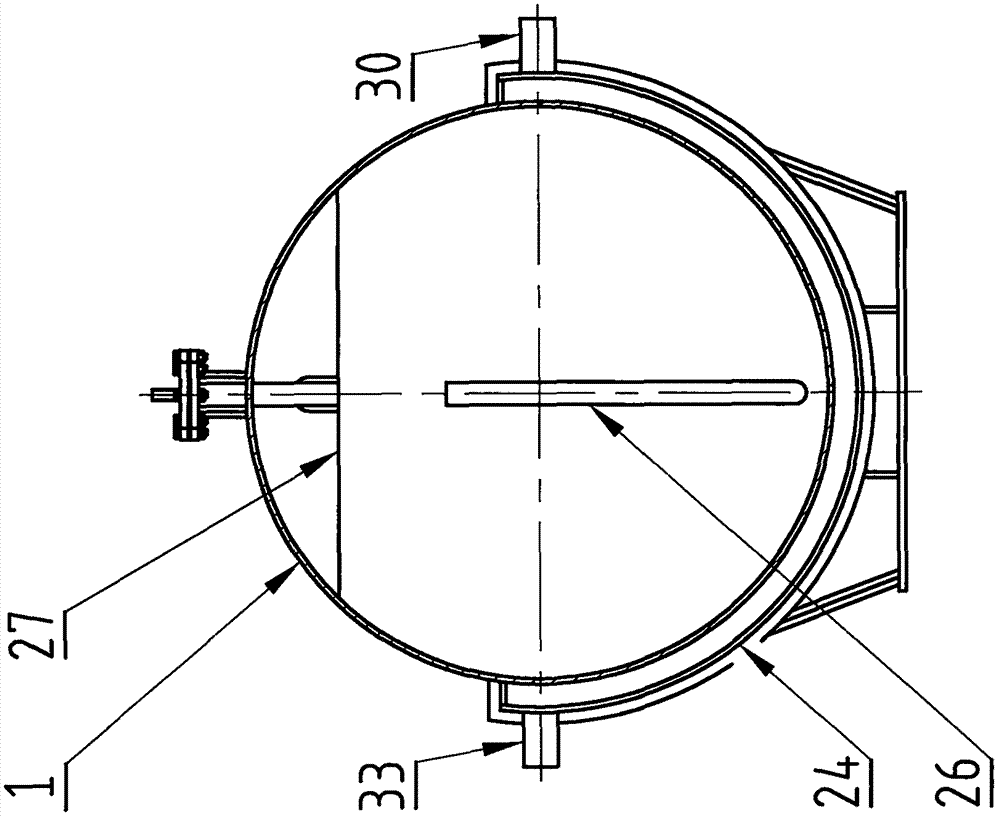

[0015] Example 1: In figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Among them, a disc-shaped partition 9 made of a steel plate is welded in the cross-sectional direction of the steel horizontal tank body 1 to separate the inside of the horizontal tank body 1 into two independent closed cavities on the left and right, respectively. For the left cavity 16 and the right cavity 6, the cross-sectional direction of the horizontal tank body 1 in the left cavity 16 is welded with a disc-shaped left dividing plate 14 with a gap on the top made of a steel plate to connect the left cavity 16 The interior is divided into two cavities, respectively, the left residual liquid chamber 18 and the left vaporization chamber 20. The left residual liquid chamber 18 and the left vaporization chamber 20 are communicated through the upper gap of the disc-shaped left partition 14, and are also connected in the right cavity. The cross-sectional direction of the horizontal t...

Embodiment 2

[0017] Example 2: In figure 1 and figure 2 In the bubbling vaporizer of the present invention, the diameter of the through hole 28 on the left air disc 22 at the bottom of the left vaporization chamber 20 can also be made into 10 mm, and the number N of the through holes is still obtained according to the empirical formula obtained from the test results of the present invention. Calculation and rounding: N=19Q / R 2 , where Q and R are the design air supply volume of the bubbler vaporizer and the radius of the through hole, respectively, and the units are m 3 / h and mm, for example: the design gas supply volume of the bubbling vaporizer in the present embodiment 2 is 150 (m 3 / h), the radius of the through hole is 5mm, then the number of through holes N=(19×150) / (5×5)=114 (holes), which can be rounded to 110 holes, and the holes are arranged in the following way : along the width direction of the left air disk 22, the spacing distance is distributed in 10 rows, and each row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com