Wide-effect energy-saving type centrifugal pump impeller design method

A centrifugal pump impeller and design method technology, applied in calculation, instrumentation, geometric CAD, etc., can solve the problems of narrow high-efficiency area and poor adaptability of the impeller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

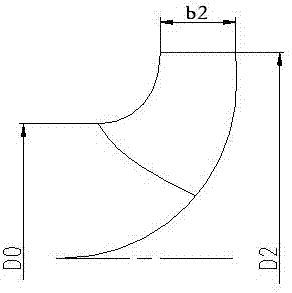

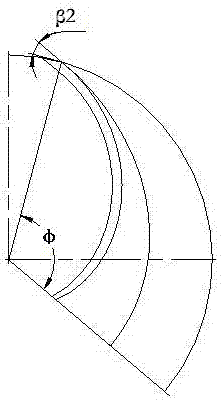

[0046] A wide-efficiency energy-saving centrifugal pump impeller design method, the outer diameter of the impeller, the equivalent inner diameter of the impeller inlet, and the width of the impeller outlet are as follows: figure 1 As shown, the blade wrap angle and blade outlet placement angle are as follows figure 2 As shown, the relationship between these geometric parameters and the performance parameters of the pump design operating point is suitable for the following relationship:

[0047] 1) Impeller outlet width b 2 Take the wider impeller outlet width, often take:

[0048] b 2 = 2.56 (ns / 100) 0.99 (2gH) 0.5 / n (m) ns<80

[0049] b 2 = 0.7 (ns / 100) 0.7 (Q / n) 1 / 3 (m) 80

[0050] b 2 = 1.6 (ns / 100) 0.99 (2gH) 0.5 / n + 0.4 (ns / 100) 0.7 (Q / n) 1 / 3 (m)ns>180

[0051] 2) The outer diameter of the impeller D 2 , for low specific speed pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com