Technology for reducing etching lines on diffuse surface

A diffusion surface and process technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of unstable protection diffusion surface, water film layer rupture, shaking, etc., to reduce the diffusion surface The generation of bad etching lines, the reduction of bad isolation, and the effect of short coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

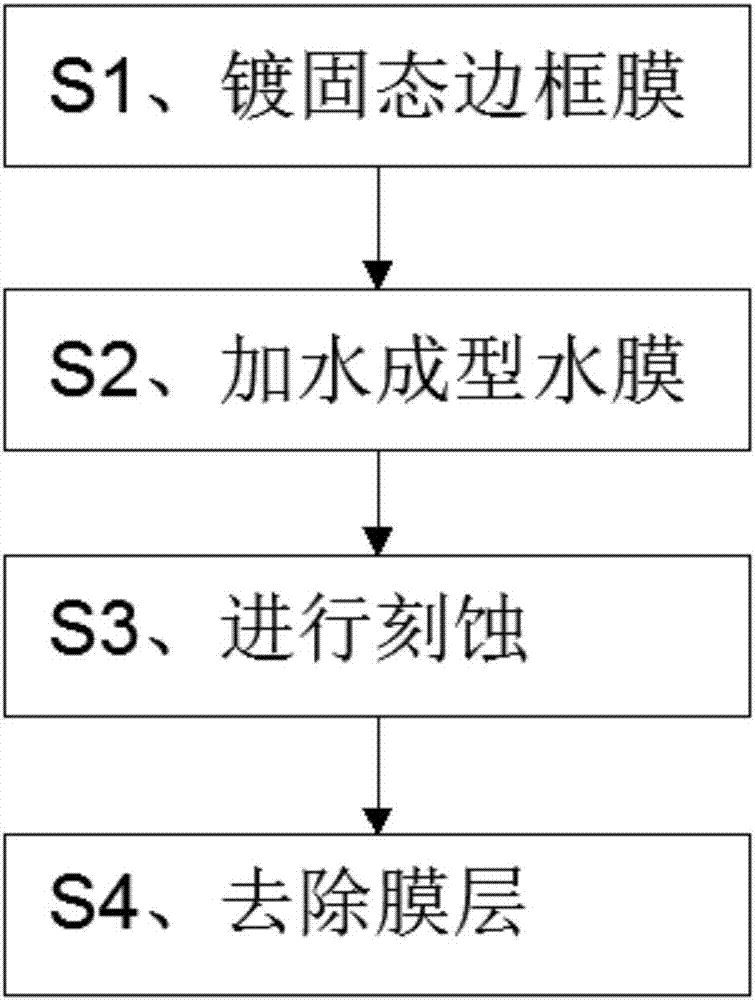

[0022] A process for reducing etching lines on a diffusion surface, comprising the following steps:

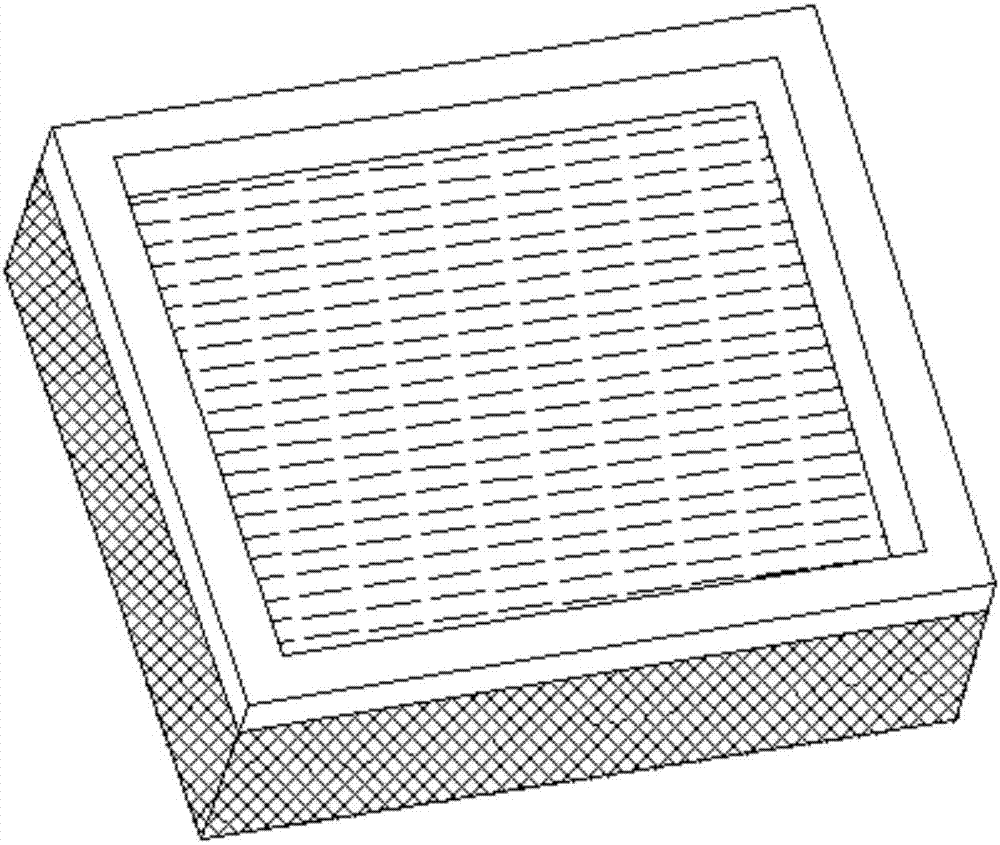

[0023] S1, plated solid frame film: as attached to the manual figure 2 As shown, the bottom filling part is a silicon wafer, and the blank part is a solid frame film. At present, the most common silicon wafer in the world has a side length of 156mm and a thickness of 0.2mm. Taking this as an example, along the diffusion surface of the silicon wafer to be etched The edge is coated with a layer of solid frame film. The width and height of the solid frame film are too large to waste materials, and the width and height are too small to protect the diffusion surface. After many experiments, the width of the solid frame film is plated to 1mm , the height is 0.9mm;

[0024] Choosing paraffin to make the solid frame film can well prevent the solid frame film from being etched by the etching solution, and the strength is enough to protect the subsequent added water film.

[0025] S2...

Embodiment 2

[0030] A process for reducing etching lines on a diffusion surface, comprising the following steps:

[0031] S1, plated solid frame film: as attached to the manual figure 2 As shown, the bottom filling part is a silicon wafer, and the blank part is a solid frame film. At present, the most common silicon wafer in the world has a side length of 156mm and a thickness of 0.2mm. Taking this as an example, along the diffusion surface of the silicon wafer to be etched The edge is coated with a layer of solid frame film. The width and height of the solid frame film are too large to waste materials, and the width and height are too small to protect the diffusion surface. After many experiments, the width of the solid frame film is plated to 2mm , the height is 0.6mm;

[0032] Choosing paraffin to make the solid frame film can well prevent the solid frame film from being etched by the etching solution, and the strength is enough to protect the subsequent added water film.

[0033] S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com