System and method for treating scale waste residue

A treatment method and oxide scale technology, which is applied in the field of oxide scale waste residue treatment system, can solve the problems of inconvenient salvage method of oxide scale waste residue, long cycle of oxide scale removal wastewater, and easy rupture of waste water tank, so as to realize energy reuse and reduce waste water. Short storage period and the effect of reducing water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

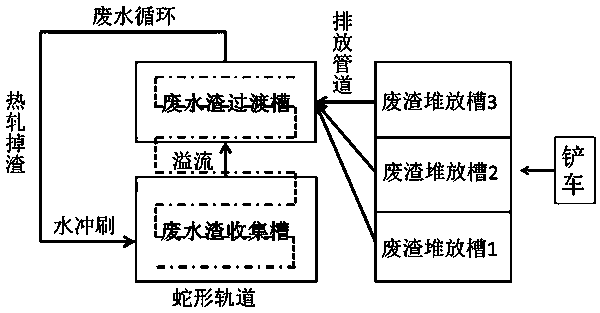

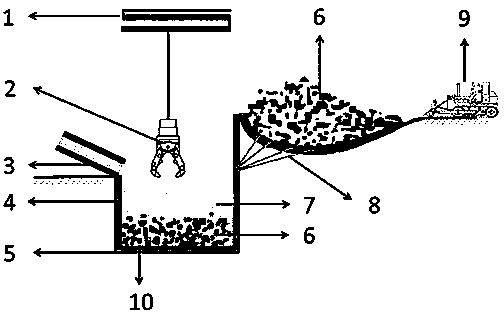

[0022] A treatment system for scale waste slag, characterized in that the treatment system for scale waste slag includes: a water flushing system, a scale waste water slag collection tank, a scale waste water slag transition tank, a number of scale waste slag storage tanks, waste water discharge pipes, Waste water circulation system, scale transfer forklift, steel claw transport system. Among them, the oxide skin wastewater slag collection tank and the oxide scale wastewater slag transition tank are located below the ground level, and the bottom of the tank includes the bottom layer of the tank composed of lime and plain soil, with a thickness of 20~25cm; and then paving gravel and resin on the bottom layer of the tank. The anti-seepage layer has a thickness of 15~20cm; finally, a concrete layer composed of stones, cement and sand is poured on the anti-seepage layer. They are all inverted trapezoidal or square, the depth of the water tank is 15~20m, the opening of the water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com