Cutting-free cement block and cement wall casting equipment and construction method

A construction method and cement technology, applied in the field preparation of building components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problem of large area, low pressure, It can not be formed at one time, so as to achieve the effect of optimizing the occupied space and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further explained and illustrated below in conjunction with the accompanying drawings and specific embodiments.

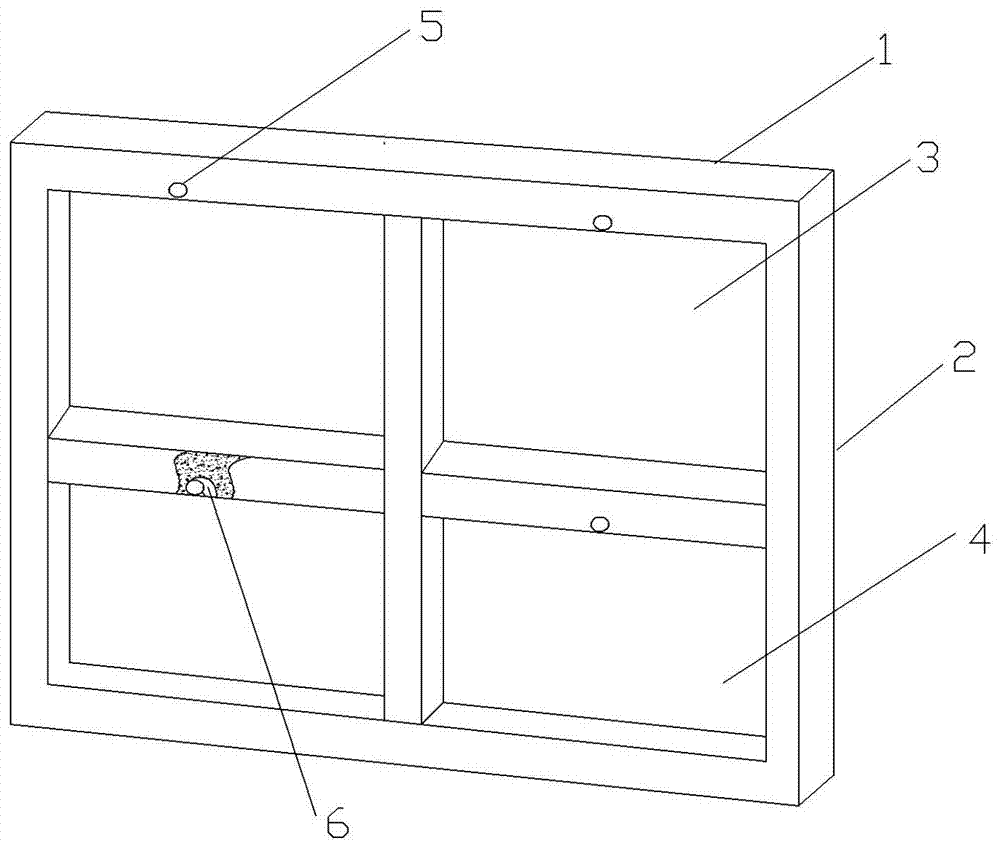

[0026] Such as figure 1 As shown, the pouring equipment for cutting-free cement blocks and cement walls of the present invention includes a beam 1, a vertical beam 2, and a protective plate coated on the periphery of the beam 1 and the vertical beam 2. The beam 1, the vertical beam 2 and the guard The upper cavity 3 and the lower cavity 4 formed by the plate enclosure; the side of the beam 1 is provided with a feed port 5; the inside of the beam 1 is provided with a feeding pipe 6;

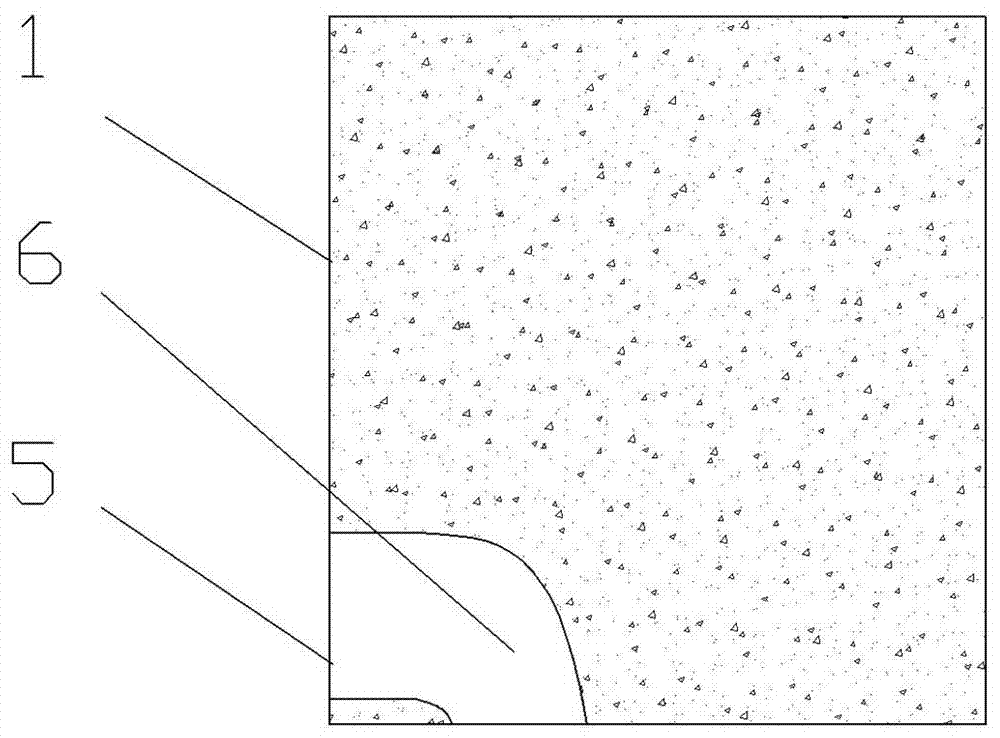

[0027] Such as figure 2 As shown, the feeding port 5 and the feeding pipe 6 are all arranged at a position less than 1 / 4 of the height of the beam 1, communicating with the cavity and the outside of the protective plate; 1 / 4 of the thickness of the beam, this design prevents the load-bearing effect of the beam from being affected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com