Method for repairing and reinforcing underground round large pipeline by utilizing fiber cloth composite material

A composite material and fiber cloth technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problems of limited reinforcement and can not significantly improve the bearing capacity of the pipe wall, etc., to achieve easy operation and reduce water transport The effect of loss, simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to be easy to understand the technical means, creative features, goals and effects of the present invention, the present invention will be further elaborated below.

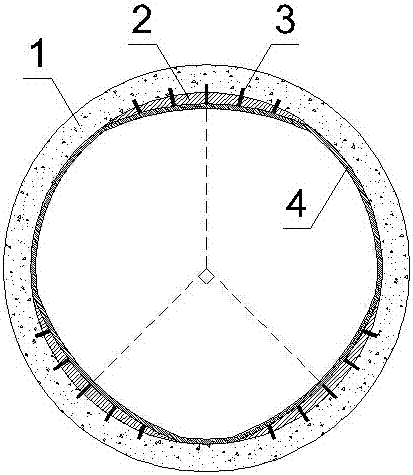

[0023] Such as figure 1 As shown, the top of the inner wall of the pipeline 1 to be reinforced, 45 degrees to the lower left, and 45 degrees to the lower right are pasted and anchored with a crescent-shaped block material 2 by glue and anchors 3, and the crescent-shaped block material 2 and the inner surface of the pipeline are used without Toxic Epoxy Glue Paste Fiber Composite 4.

[0024] Specific implementation method:

[0025] A method for repairing and strengthening an underground circular large pipeline with a fiber cloth composite material comprises the following steps:

[0026] (1) First clean and clean the damaged part of the inner wall of the pipeline;

[0027] (2) Use an angle grinder to grind and clean the inner wall of the pipeline, and repair the damaged parts of the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com