Mesh fabrics screen length deviation rate detection system based on machine vision

A machine vision and detection system technology, applied in the field of detection systems, can solve problems such as insufficient installation space of the detection system, and achieve the effects of reducing labor intensity and missed inspection rate of workers, overcoming insufficient installation space and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

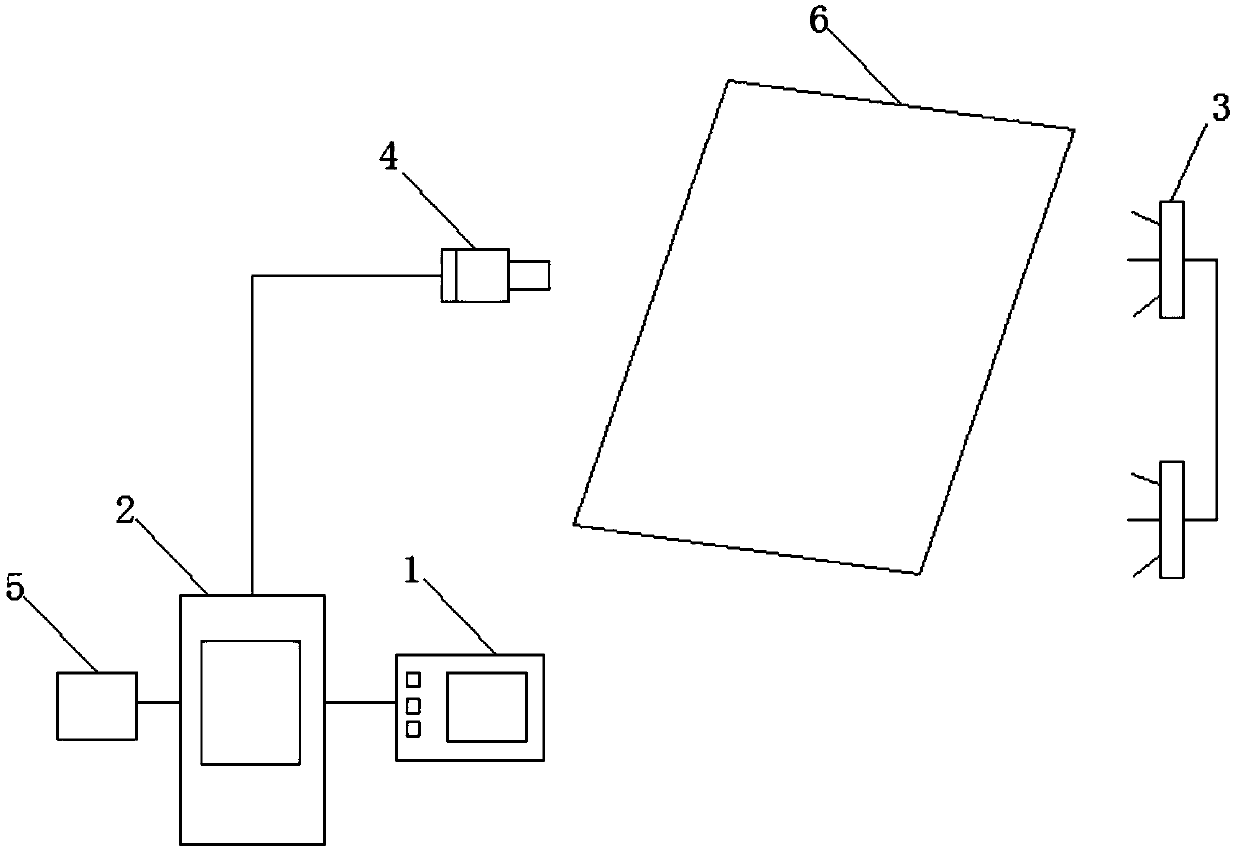

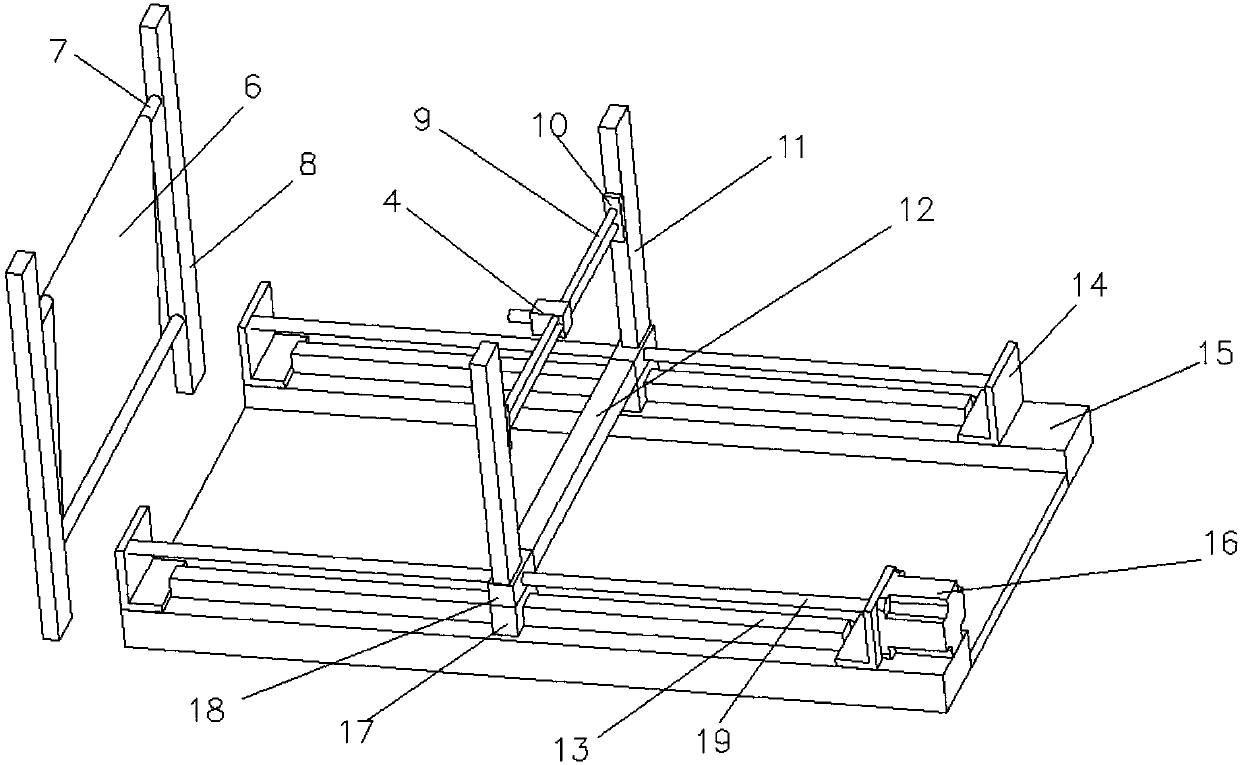

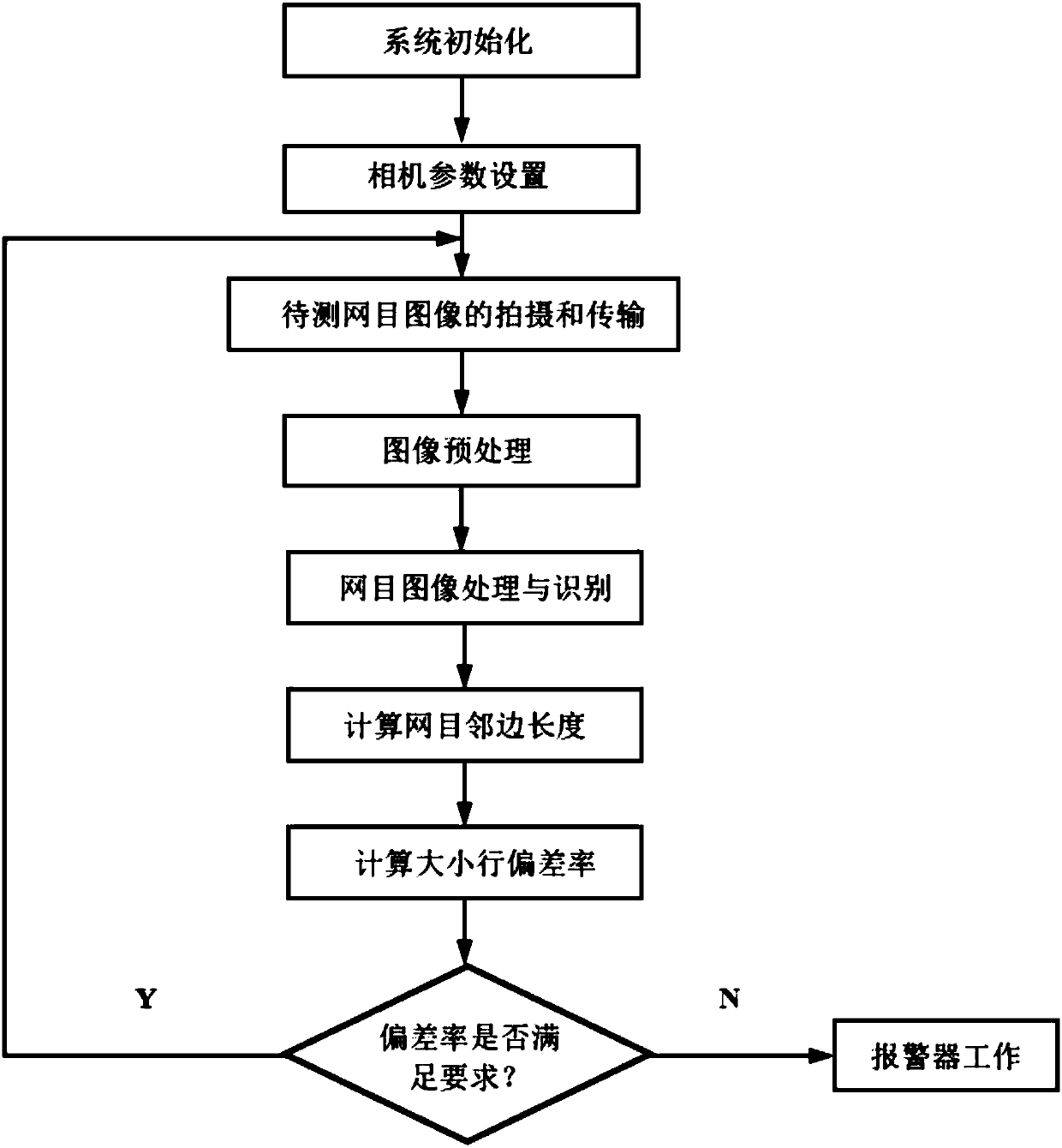

[0045] like figure 1 As shown, a kind of mesh fabric mesh length deviation rate detection system based on machine vision of the present invention includes industrial computer 2, display 1, light source 3, image acquisition card, adjustable image acquisition device and alarm 5, like figure 2As shown, the adjustable image acquisition device includes a CCD industrial camera 4 and a mobile device, the mobile device includes a base 15 and a motor 16, and the two ends of the base 15 are provided with a guide rail 13, a slide block 17, a screw support Seat 18, ball screw 19 and support frame 11, described guide rail 13 is installed on the upper surface of base 15, and described slider 17 is slidably connected with guide rail 13, and described ball screw 19 is positioned at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com