Nano cutting depth high-speed single-point scratch test device and test method thereof

A test device and nanotechnology, applied in the direction of measuring device, test material hardness, instrument, etc., can solve the problem of controlling the length of the scratch, the limited feeding speed of the scratching tool in the ball-on-disc scratching method, and the single pendulum scratching method Limiting the sampling frequency of the radius of rotation of the scratching tool, etc., to achieve the effect of controllable scratching length, reduced action time, and clear corresponding relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

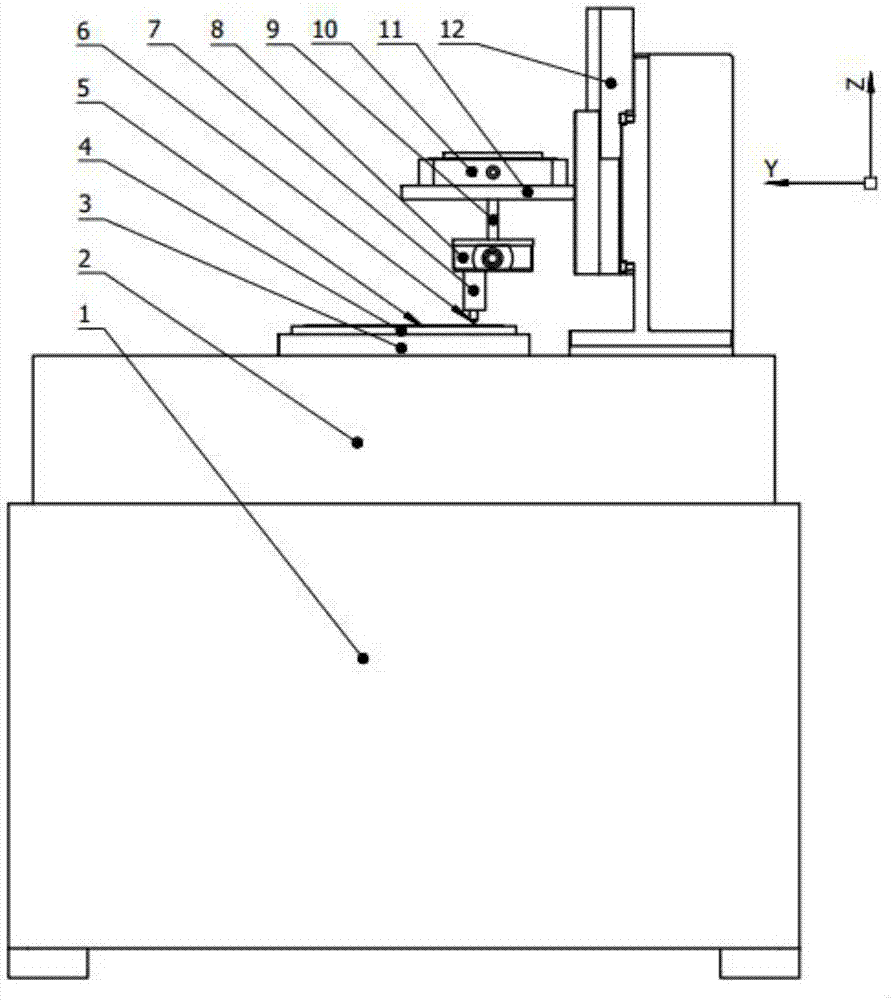

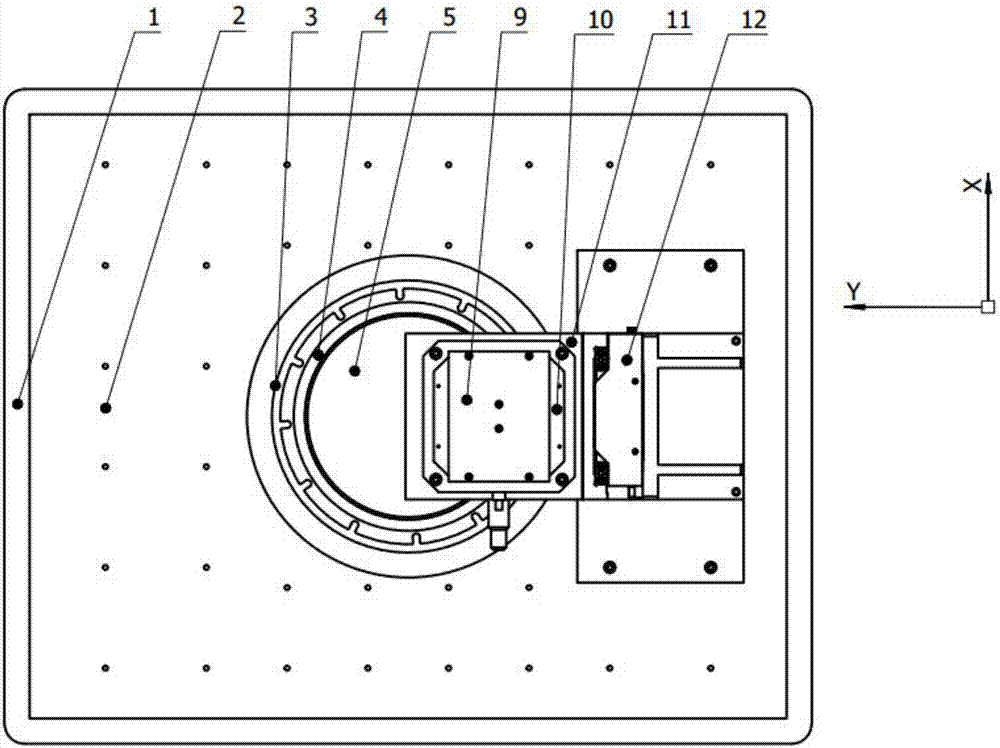

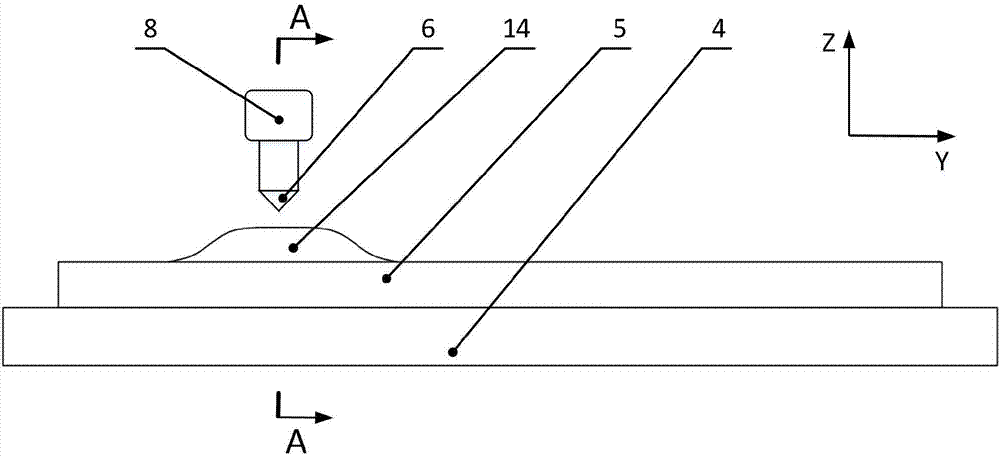

[0081] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-4 As shown, a nanometer depth of cut high-speed single-point scratch test device, including:

[0082] base 1;

[0083] The horizontally placed workbench 2 is fixedly installed on the top surface of the base 1;

[0084] The vertically placed air-floating turntable 3 is fixedly installed on the workbench 2;

[0085] The test piece fixture 4 is installed on the top end surface of the air-floating turntable 3, and is coaxial with the air-floating turntable 3, and the test piece fixture 4 is driven to rotate by the air-floating turntable 3; the test piece fixture 4 is a vacuum chuck, a magnetic chuck or a mechanical structural fixtures;

[0086] The test piece 5 is mounted on the test piece fixture 4;

[0087] The Z-direction feeding device 12 is installed on the top surface of the workbench 2, and feeds along the direction of the rotation axis of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com