Plastic-iron integrated backlight structure in liquid crystal display module

A technology of liquid crystal display module and backlight structure, applied in the direction of light guide, optics, optical components, etc., to achieve the effect of good overall strength, low production cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

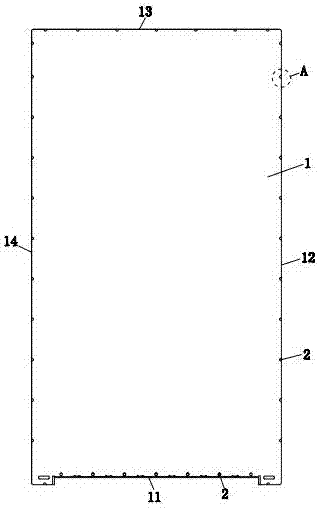

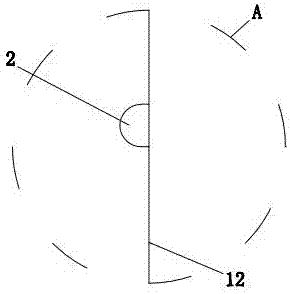

[0028] The rubber-iron integrated backlight structure in a liquid crystal display module of this embodiment, such as figure 1 and figure 2 As shown, it includes an iron frame 1 and a plastic frame injection-molded on the iron frame 1; the iron frame 1 includes a first frame 11, a second frame 12, a third frame 13, and a fourth frame 14 that enclose a rectangular structure in turn; The first frame 11 , the second frame 12 , the third frame 13 and the fourth frame 14 each have several openings, the openings are set as circular openings 2 , and in this embodiment, the diameter of the circular openings 2 is set to 0.8 mm. Since the opening of the iron frame 1 is set as a circular opening 2, the plastic-iron integrated backlight structure in the liquid crystal display module is not easily deformed and bent, and at the same time, it has the advantage of good overall strength of the product. In addition, since the diameter of the circular opening 2 is set to 0.8 mm, the opening siz...

Embodiment 2

[0032] Embodiment 2 of the rubber-iron integrated backlight structure in a liquid crystal display module of the present invention, the difference between this embodiment and Embodiment 1 is that in this embodiment, the diameter of the circular opening 2 is set to 0.7mm , so the opening size is smaller, which in turn makes the product structure better in flatness. In this embodiment, the circular openings 2 are evenly arranged on the first frame 11 and the third frame 13, and the distance between two adjacent circular openings 2 in the first frame 11 and the third frame 13 is set to 11mm, so that the product can The overall strength is good, and it will not affect the gap of the film material space inside the product, and makes the rubber-iron integrated backlight structure guaranteed to pass the reliability test of high temperature and high humidity. In this embodiment, in this embodiment, the circular openings 2 are evenly arranged on the second frame 12 and the fourth frame ...

Embodiment 3

[0034] Embodiment 3 of the rubber-iron integrated backlight structure in a liquid crystal display module of the present invention, the difference between this embodiment and Embodiment 1 is that in this embodiment, the diameter of the circular opening 2 is set to 0.9mm , so the opening size is smaller, which in turn makes the product structure better in flatness. In this embodiment, the circular openings 2 are evenly arranged on the first frame 11 and the third frame 13, and the distance between two adjacent circular openings 2 in the first frame 11 and the third frame 13 is set to 9mm, so that the product can The overall strength is good, and it will not affect the gap of the film material space inside the product, and makes the rubber-iron integrated backlight structure guaranteed to pass the reliability test of high temperature and high humidity. In this embodiment, in this embodiment, the circular openings 2 are evenly arranged on the second frame 12 and the fourth frame 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com