Commodity virtual tagging method and system based on personalized pattern

A technology of commodity coding and individuality, applied in the direction of digital marking, commerce, image communication, etc. by printing code marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

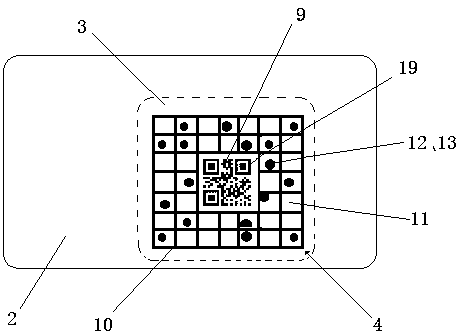

Embodiment 1

[0211] Such as figure 1 As shown, choose a 35μm thick pet film to print a 500g salt commodity (2) bag. If a total of 5 billion bags of salt products (2) need to be traced and coded, each bag of salt products (2) is given a unique product code (1), such as 20108000001, 20108000002, 20108000003, 20108000004...n and other natural sequence codes. The product code (1) is used as a traceability code. The product code (1) does not need to be printed on the salt product (2). Every 100,000 (ie n=100,000) bags are divided into groups, and each group is programmed with a unique group number⑼. The group number ⑼ is printed on the salt commodity ⑵ bag in the form of a fixed version of the two-dimensional code (that is, a fixed code segment). In this way, 5 billion bags of salt products (2) can be divided into 50,000 different group numbers (9). For example, natural sequence codes such as 00001, 00002, 00003, 00004, 00005...20108... are used as group numbers (9)—that is, as fixed code ...

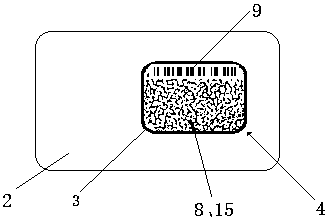

Embodiment 2

[0230] Such as figure 2 , Figure 11 As shown, choose a 35μm thick pet film to print a 500g salt commodity (2) bag. If it is necessary to carry out traceability coding for 5 billion bags of salt products (2), each bag of salt products (2) is assigned a unique product code (1). The product code (1) does not need to be printed on the salt product (2). Every 100,000 bags are divided into groups, and each group is assigned a unique group number⑼. Print the group number ⑼ on the salt product ⑵. In this way, 5 billion bags of salt products (2) can be divided into 50,000 different group numbers (9).

[0231] Print personality pattern: delineate a 16mm×26mm area on the pet film as the personality area ⑶, for each group of salt commodity ⑵ bags, print a fixed barcode group number ⑼ etc. in the area.

[0232] Using the current gravure printing or silk screen printing technology, print a layer of wrinkle or crack ink⑻ on the pet film, so that the wrinkle or crack ink in the persona...

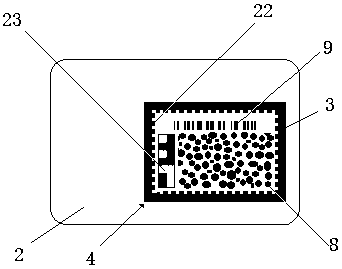

Embodiment 3

[0241] Such as image 3 As shown, the individual characteristic pattern (4) is formed after the foaming ink (8) is foamed.

[0242] Choose white cardboard to produce the medicine box. Prepare some milky UV foaming ink.

[0243] Printing individual characteristic patterns includes: using a screen printing machine to print 26mm×16mm foaming ink⑻ on white cardboard, and then irradiating it with UV curing lamps to cure and foam.

[0244] Printing individual characteristic patterns also includes: making another flexo printing plate of 24mm×14mm, printing on the foaming ink layer ⑻ with red flexo printing ink, so as to print and dye the peak of the bubble in red, that is, at the peak of the bubble A colored ink layer different in color from the foaming ink ⑻ is printed on the top and dried. The dwarf peaks, being too short to reach the plate, were not stained red.

[0245] Since each bubble is formed by random foaming, manpower cannot control its shape, size and height. Their p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com