Production device suitable for extremely-fine copper axial wire

A technology of production device and wire gathering device, which is applied in the manufacture of wire harnesses, conductor/cable insulation, electrical components, etc., can solve the problems of insufficient fineness, small operating space, and low flexibility, and achieve good space utilization and fixed The effect of stable extraction and small space resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

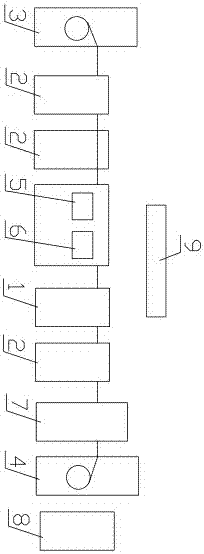

[0065] Example 1, such as figure 1 As shown, a production device suitable for fine copper shafts, a production device suitable for fine copper shafts, includes a wire stretching device 3 for spreading out the copper shafts and a wire collection device 4 for collecting copper shafts, The copper axis advances in the horizontal direction, and the first taping module, the second taping module, the high-temperature baking device 5, the inspection device 6, the weaving Device 1, the third strapping module and laser caliper 7, the first strapping module, the second strapping module and the third strapping module all include strapping device 2; also include server 9, the first strapping module, The second taping module, the high temperature baking device 5 , the inspection device 6 , the weaving device 1 , the third taping module and the laser diameter measuring device 7 are all separately connected to the server by communication.

[0066] There are many processes in the production o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com