Starting circuit of PWM chip of super-wide voltage auxiliary power supply

An auxiliary power supply and ultra-wide voltage technology, applied in the direction of electrical components, output power conversion devices, etc., can solve problems such as shortage of use, high cost, affecting power conversion efficiency, heat dissipation and reliability, etc., to achieve reliable work, The effect of small circuit loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

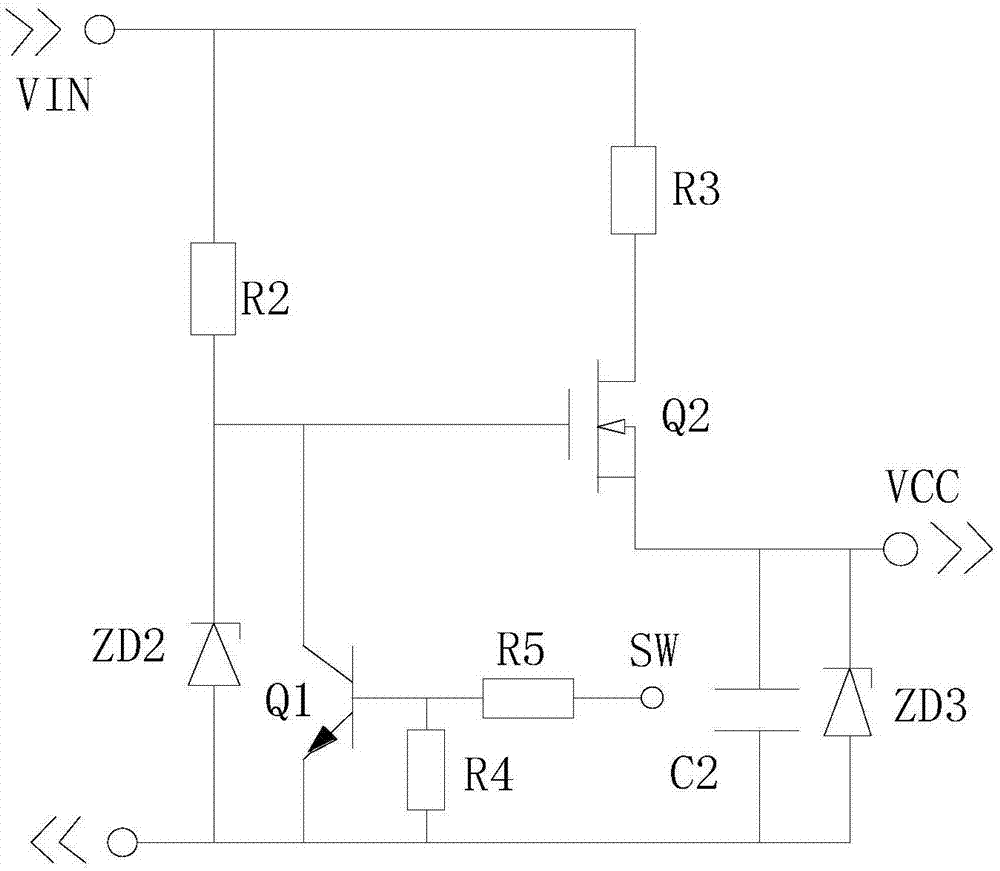

[0047] See Figure 5 , A startup circuit of an ultra-wide voltage auxiliary power supply PWM chip, including a voltage switch circuit 1, a voltage detection circuit 2 and a charging circuit 3. The voltage switch circuit 1 is composed of a MOS tube Q1, a resistor R4 and a resistor R5; a voltage detection circuit 2 is composed of MOS tube Q2, resistance R7 and resistance R8; charging circuit 3 is composed of resistance R1 and resistance R2; the drain of MOS tube Q1 is connected to one end of resistance R1 and resistance R2, and the other end of resistance R1 is connected to the voltage input interface +Vin terminal, the other end of resistor R2 is connected to the source of MOS transistor Q1 and the source of MOS transistor Q2, the gate of MOS transistor Q1 is connected to the drain of MOS transistor Q2; the gate of MOS transistor Q1 is connected to MOS transistor Q2 The connection line of the drain of the resistor R4 is also connected to the voltage input interface +Vin terminal,...

Embodiment 2

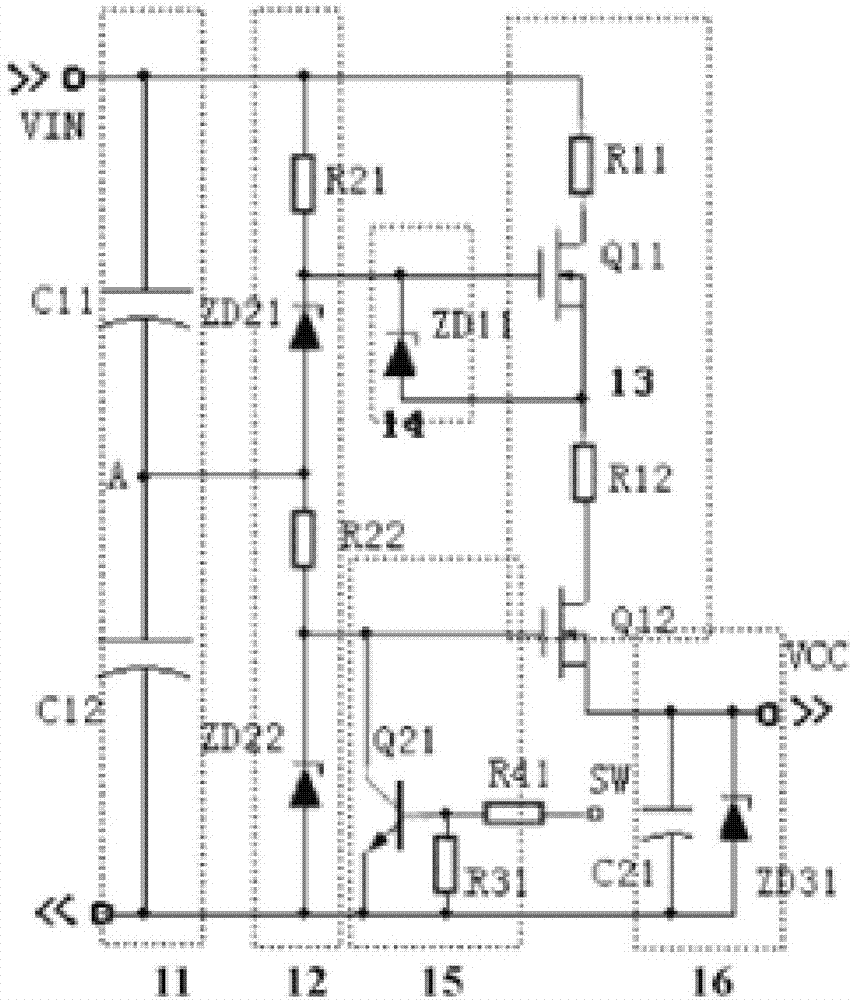

[0062] See Image 6 , Is a schematic diagram of a two-stage voltage divider series circuit, when applied to 100-1000VDC, the advantages are obvious; the explanation is as follows, when the minimum input voltage is 100VDC, the charging current is set to: 50uA, then the charging resistance value is: R1=R2 =R3=100VDC / 50uA=2MΩ, the same as the above analysis, when input voltage, the charging current is only: I=Vinmax / (R1+R2+R3)=1000VDC / 6MΩ=166mA, the current change is only 1:3. The power loss is: P=I*Vinmax=166mW. Image 6 The voltage of MOS tube Q1 and MOS tube Q3 should be: V Q1 =V Q3 =1 / 3Vinmax=330VDC.

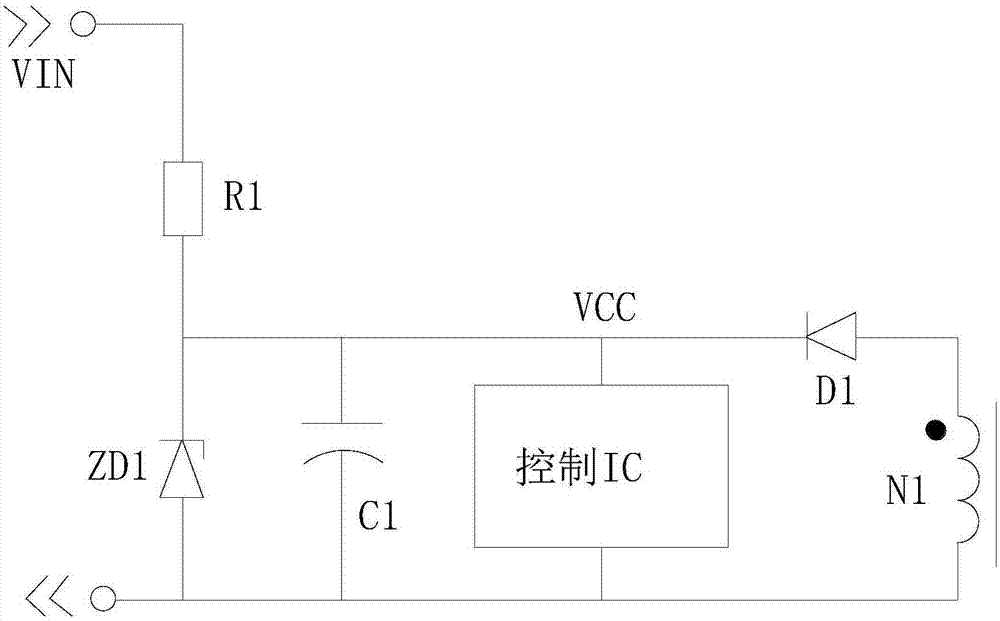

[0063] Figure 1-Figure 4 , The charging current is 50-500uA, the current change is very large, nearly 1:10, and the power loss is P=I*Vinmax=500mW.

[0064] figure 2 The voltage in the MOS tube Q2 should be V Q2 =Vinmax=1000VDC, image 3 In Q11, Q12 is V Q11 =V Q12 =1 / 2Vinmax=500VDC.

Embodiment 3

[0066] See Figure 7 , Is a schematic diagram of a three-stage voltage divider series circuit. When applied to 100-2000VDC, the advantages are more prominent; the explanation is as follows, when the minimum input voltage is 100VDC, the charging current is set to: 50uA, then the charging resistance value is: R1=R2 =R3=R41=100VDC / 50uA=2MΩ, the same as the above analysis, when input voltage, the charging current is only: I=Vinmax / (R1+R2+R3+R41)=1000VDC / 8MΩ=125uA, the current change is only 1:2.5. The power loss is: P=I*Vinmax=250mW. Figure 7 The voltage of Q1, Q3, and Q5 should be: V Q1 =V Q3 =V Q5 =1 / 4Vinmax=500VDC.

[0067] Figure 1-Figure 4 , The charging current is 50-1000uA, the current change is very large, nearly 1:20, and the power loss is P=I*Vinmax=2000mW.

[0068] figure 2 The voltage in the MOS tube Q2 is V Q2 =Vinmax=2000VDC, image 3 , Figure 4 In the MOS tube Q11, MOS tube Q12, Qa, Qb are V Q11 =V Q12 =1 / 2Vinmax=1000VDC.

[0069] Among the above points 4 and 5, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com