Building external wall provided with crack-processing fiber pipes

A technology of building exterior walls and fiber tubes, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of falling off, causing danger, entering moisture, etc., and achieves good strength and tensile strength, not easy to break and crack, and construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

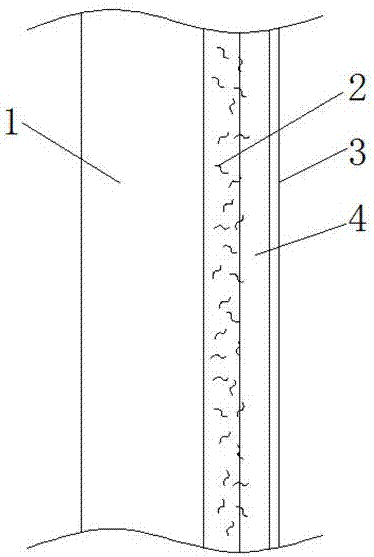

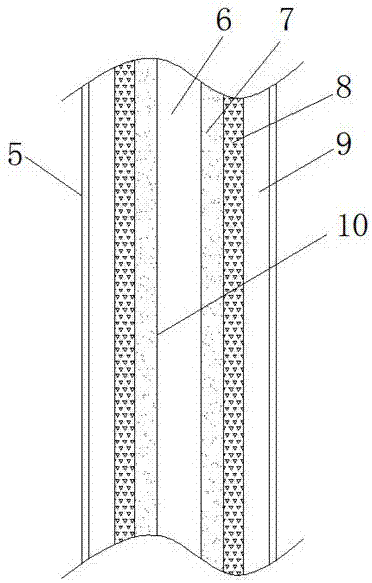

[0030] See Figure 1-2 , A kind of building exterior wall with cracking treatment fiber tube, including wall body 1, wall body 1 is laid with outer wall 4, outer wall 4 is laid with protective layer 3, outer wall 4 is mixed with fiber tube 2, fiber The tube 2 includes a protective film 5, an outer film 9 and a diaphragm 10. The protective film 5 is laid on the outer surface of the outer film 9. The inside of the outer film 9 is separated by the diaphragm 10 from the inner compartment 6, the intermediate area 7 and the outer compartment 8, and The inner compartment 6, the middle compartment 7 and the outer compartment 8 are arranged in sequence from the inside to the outside. The inner compartment 6 is filled with a mixture of cement-based powder and potassium iodide powder, and the compartment 7 is filled with reactive powder concrete. The compartment 8 is filled with polyurethane grouting powder. Before the fiber tube 2 is disconnected, the cement-based powder, potassium iodid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com