Automatically-controlled high-stability pressure-maintaining core-removing device

A coring device and high-stability technology, which is applied in the direction of undisturbed core extraction, earthwork drilling and mining, etc., can solve problems such as damage to the pressure-holding mechanism, insufficient compacting force, and impact of flip cover, achieving good sealing and convenient operation and use , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

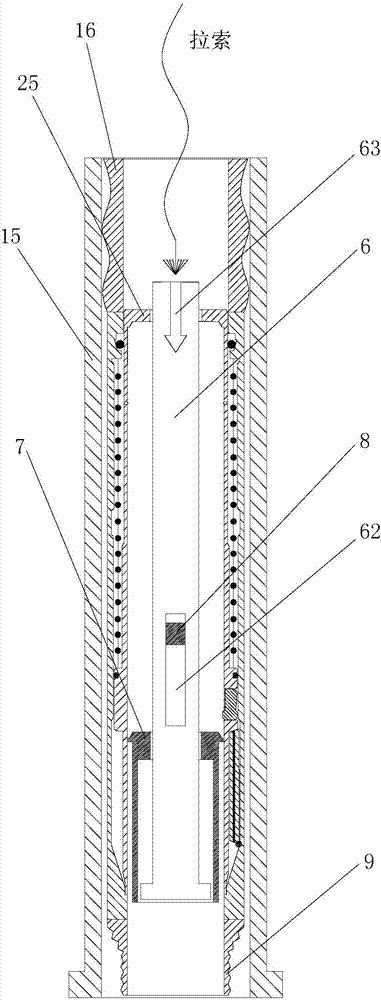

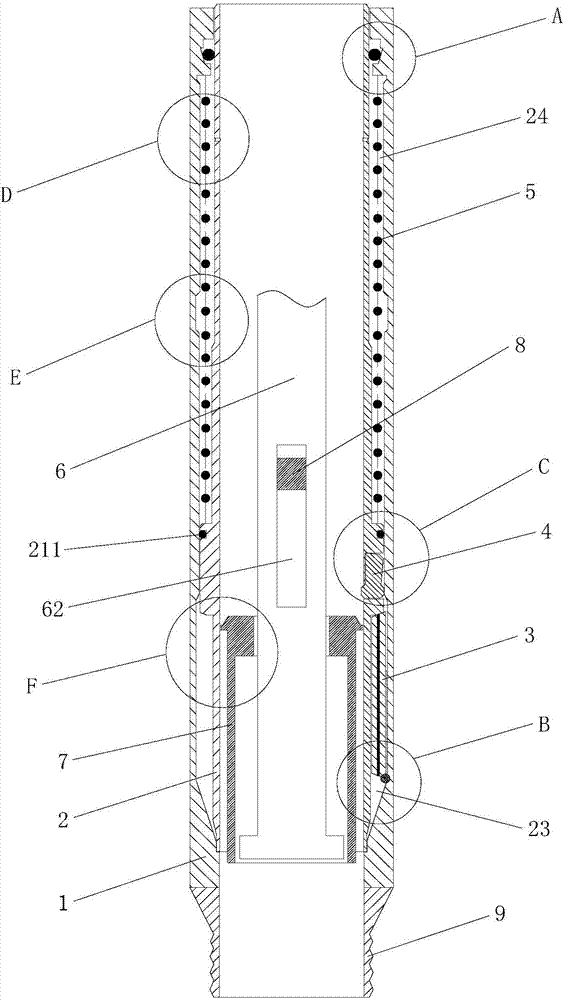

[0025] Such as Figures 1 to 8 As shown, the automatically controlled high-stability pressure-holding coring device of the present invention includes a pressure-holding outer cylinder 1, a pressure-holding inner cylinder 2, a flip cover 3, a slider 4, a spring 5, a central rod 6, a PVC pipe 7, an energy storage device 8 and PDC bit 9.

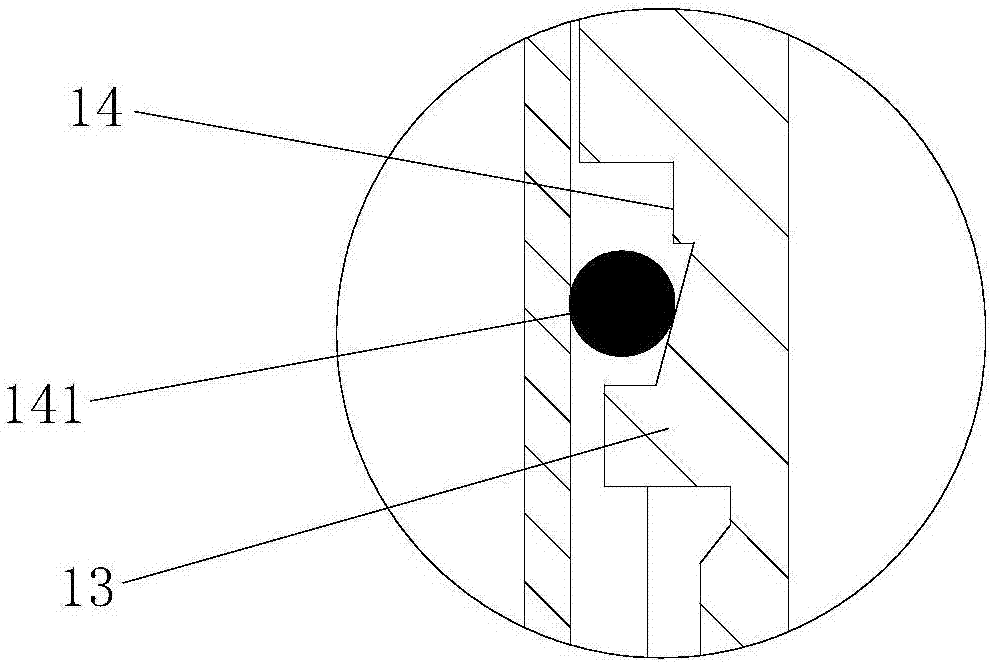

[0026] The pressure-holding outer cylinder 1 has an integral structure, wherein the inner wall of the lower section is provided with a mounting groove 11 along the circumferential direction, the inner wall of the middle and upper section is provided with a groove 12 along the circumferential direction, and the inner wall of the top end protrudes outward to form a raised portion 13 of the outer cylinder. A trapezoidal valve port 14 is opened in the middle and lower section of 13 along the circumference; a sealing ring 141 is embedded inside the trapezoidal valve port 14, and the upper end inner wall of the pressure maintaining outer cylinder 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com