Flexible recyclable material-based space consumption type heat dissipation working medium recycling method

A technology of heat dissipation working medium and recovery method, which is applied in the field of spacecraft thermal control, can solve the problem that space consumption type heat dissipation working medium cannot be recycled and reused, restricts consumption type heat dissipation, etc., and achieves the effect of avoiding secondary separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

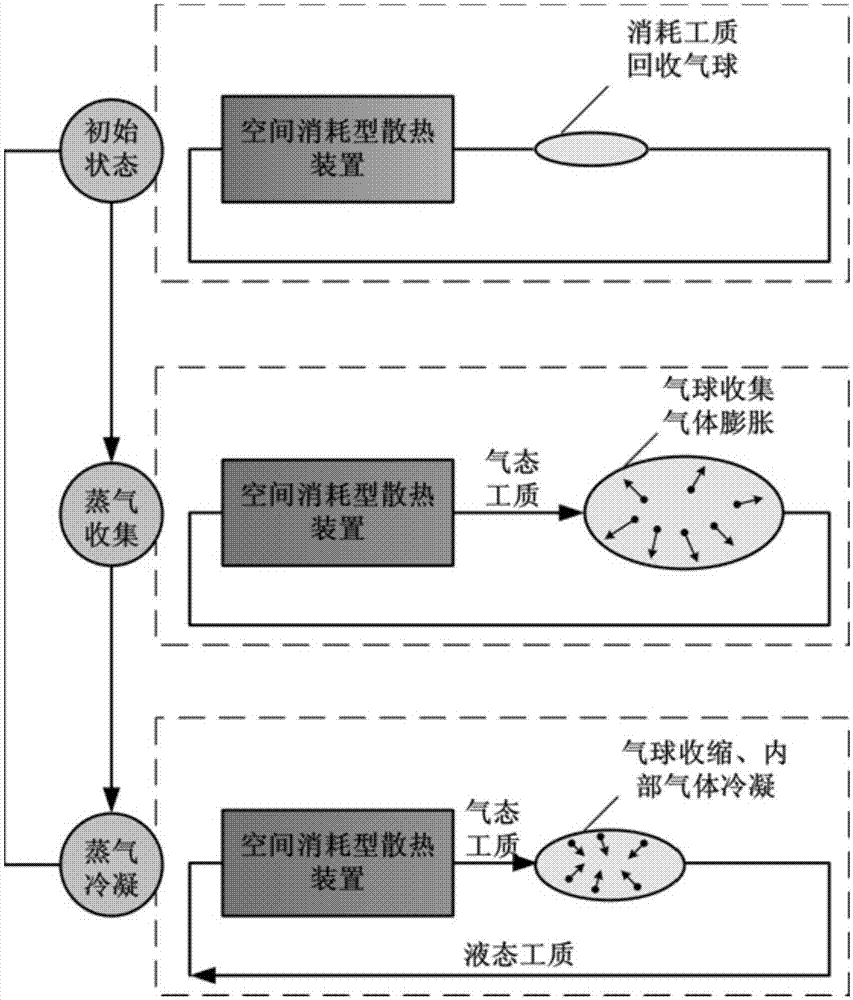

[0027] The present invention proposes a method for recovering space-consuming heat-dissipating working fluid based on flexible and recyclable materials, and its specific implementation is as follows:

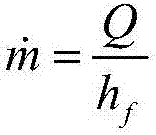

[0028] (1). Estimate the required liquid working fluid quality according to the peak heat load, working time, working fluid type and working temperature of the spacecraft thermal control system.

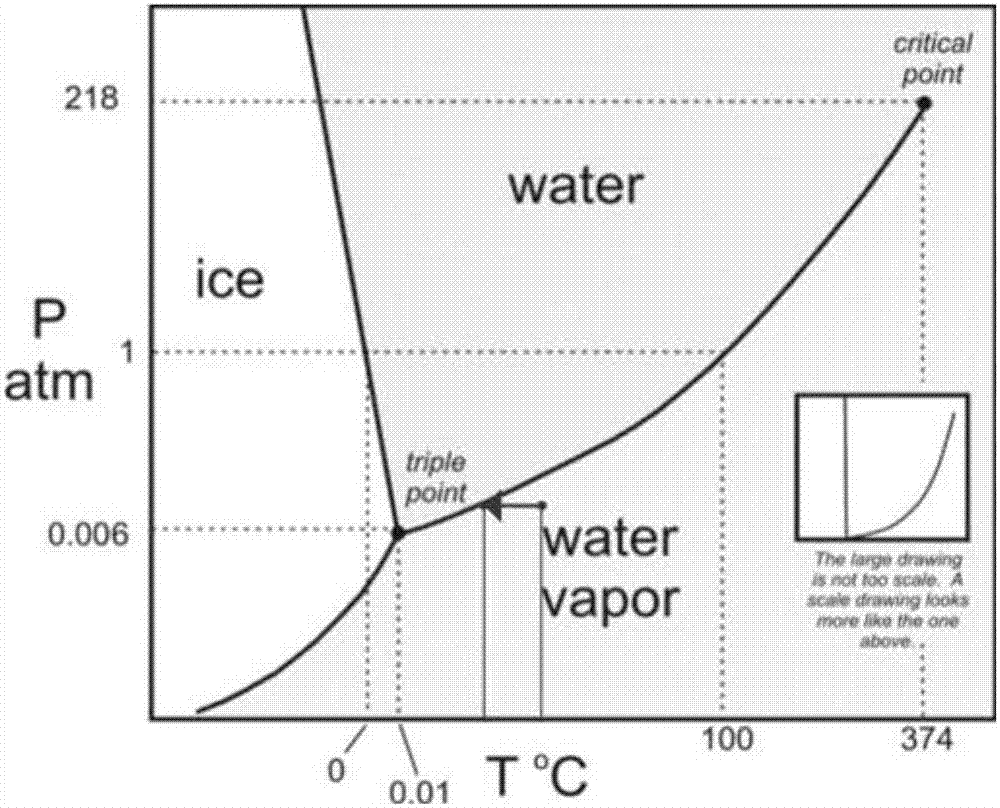

[0029] (2). Set the maximum working back pressure according to the working back pressure requirements of the consumable cooling device; estimate the volume of the gaseous working medium evaporated during the working process of the equipment based on the estimation of the quality of the working medium and the maximum working back pressure.

[0030] (3). Select a flexible and recyclable material, and modify its surface by surface superhydrophobic treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com