Emulsifying device

An emulsification device and the technology of the first fluid, applied in the directions of transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unsatisfactory emulsification effect, achieve the effect of reducing pressure drop and improving emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are described below with reference to the drawings, in which like parts are denoted by like reference numerals. In the case of no conflict, the following embodiments and the technical features in the embodiments can be combined with each other.

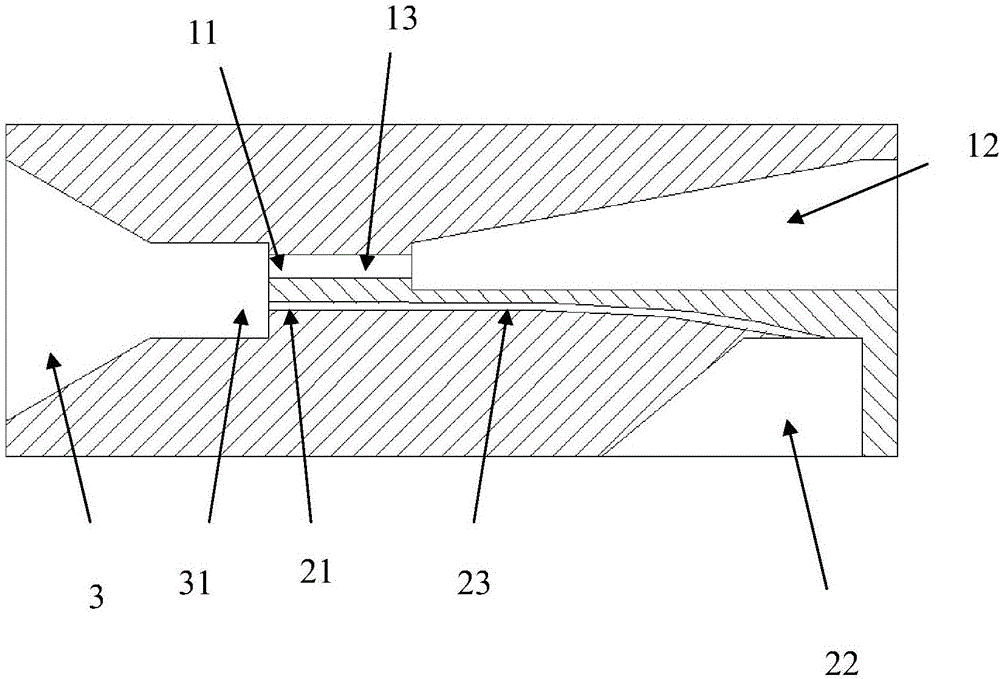

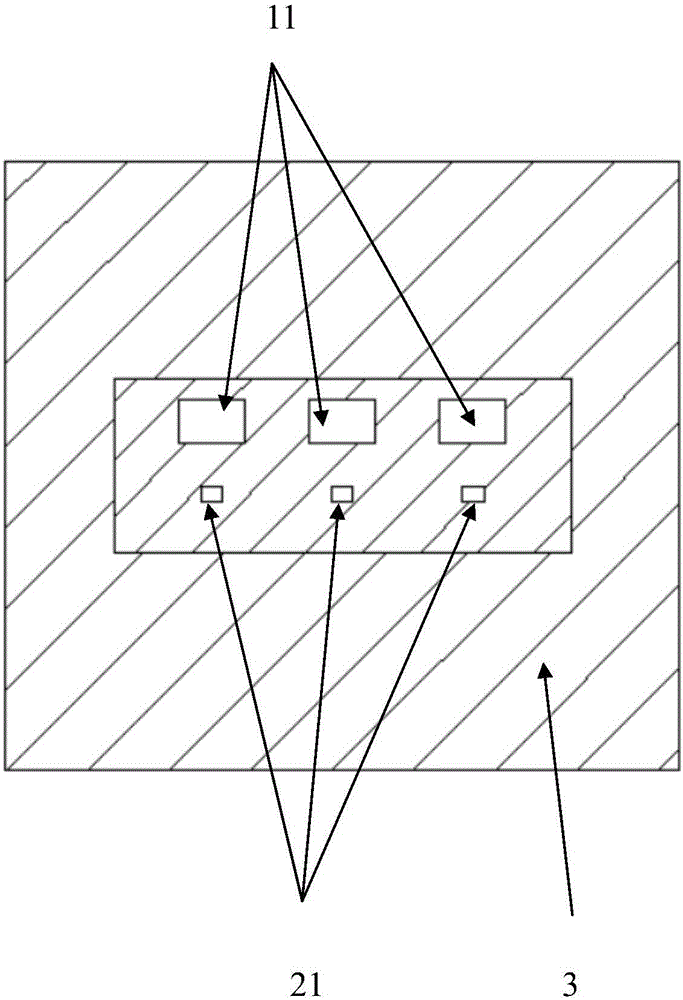

[0015] figure 1 shows the structural diagram of the emulsification device of the present invention, to be precise, figure 1 is a side sectional view. The emulsifying device of the present invention comprises: a first fluid channel 13 for high-viscosity fluid, a second fluid channel 23 for low-viscosity fluid, the fluid inlet end of the first fluid channel 13 is connected to the first fluid guide 12, The fluid inlet end of the second fluid channel 23 is connected to the second fluid guide 22 . The first fluid outlet 11 of the first fluid channel 13 and the second fluid outlet 21 of the second fluid channel 23 are commonly connected to the diversion header 3 . The diversion header 3 is loc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com