Efficient large selective laser melting forming device

A laser melting and selective technology, applied in the direction of manufacturing auxiliary devices, improving energy efficiency, improving process efficiency, etc., can solve problems such as damage, complex structure, interruption of processing process, etc., to save the use of inert gas and improve the compactness of structure 、To overcome the effect of small forming size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

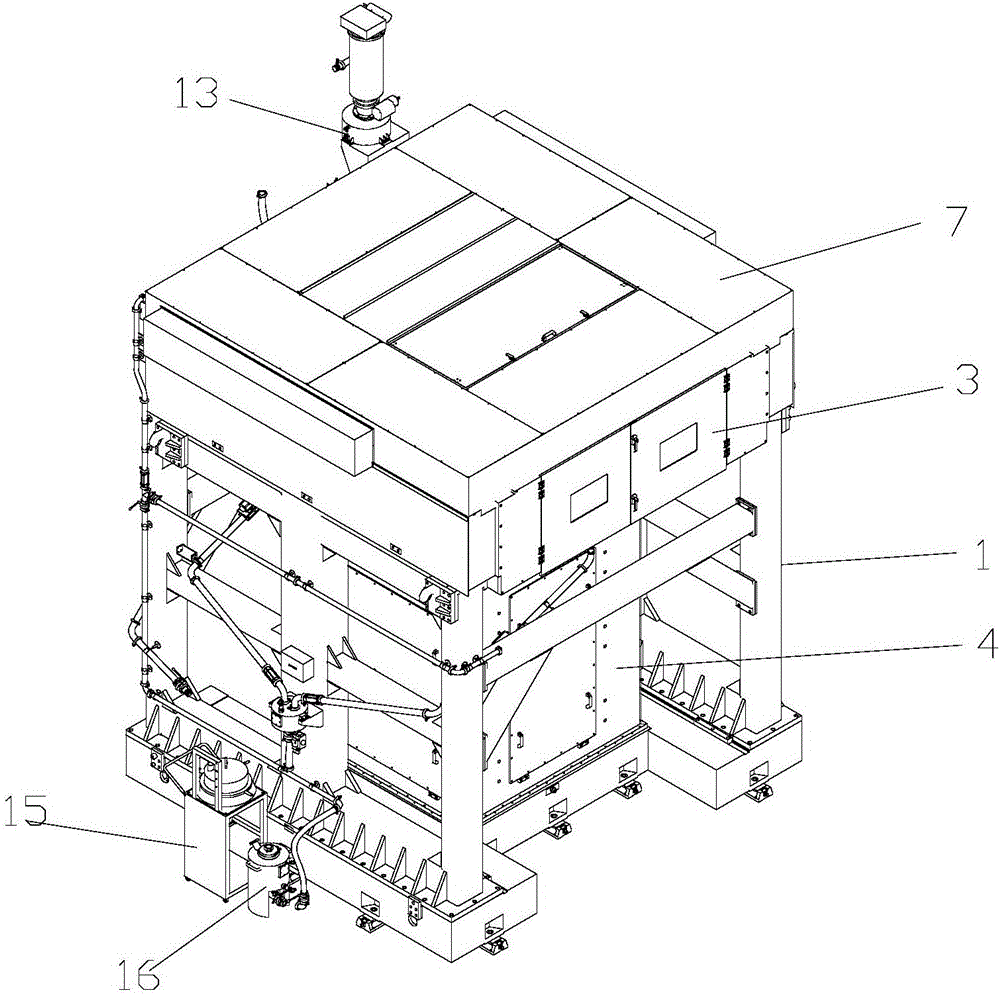

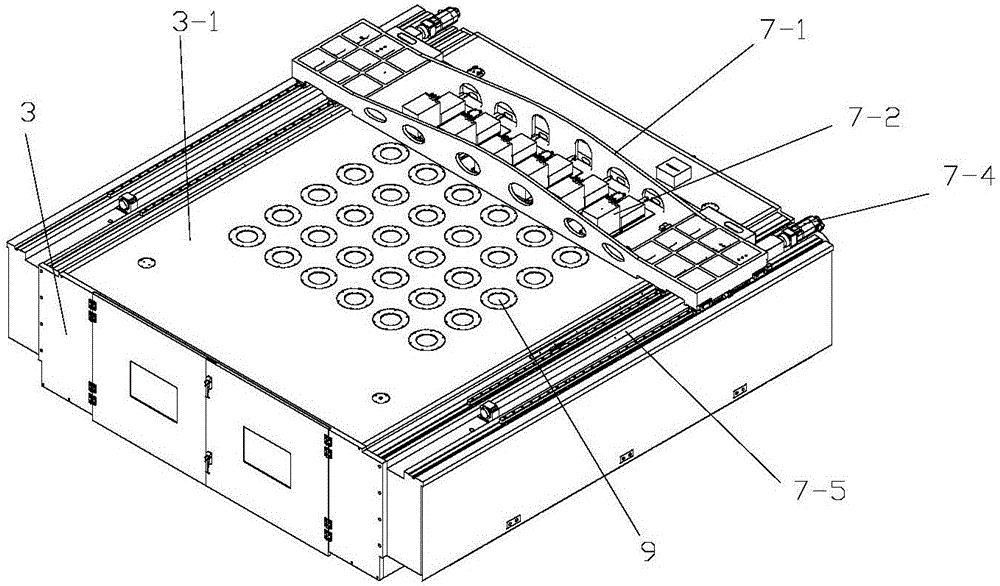

[0036] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 It is a schematic diagram of the overall structure of the vibrating mirror scanning device in the present invention, image 3 It is a schematic diagram of the working state of the vibrating mirror scanning device in the present invention, Figure 4 It is a schematic diagram of scanning the overlapping area of the galvanometer scanning device in the present invention, Figure 5 It is a structural schematic diagram of the blowing and smoking mechanism in the present invention, Figure 6 It is a structural schematic diagram of the filtering device in the present invention, Figure 7 It is a working schematic diagram of the powder circulation system in the present invention, Figure 8 It is a schematic diagram of the installation structure of the powder circulation system in the present invention, Figure 9 It is a schematic diagram of the forming workbench movement in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com