Inclined end surface milling and center hole drilling machine tool

A technology for drilling a center hole and milling an end face, which is applied in the field of oblique milling end face drilling center hole machine tools, can solve problems such as changes in working accuracy, batch scrapping of workpieces, and thermal deformation of guide rails, and achieves good cutting rigidity, high precision, and chip removal. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

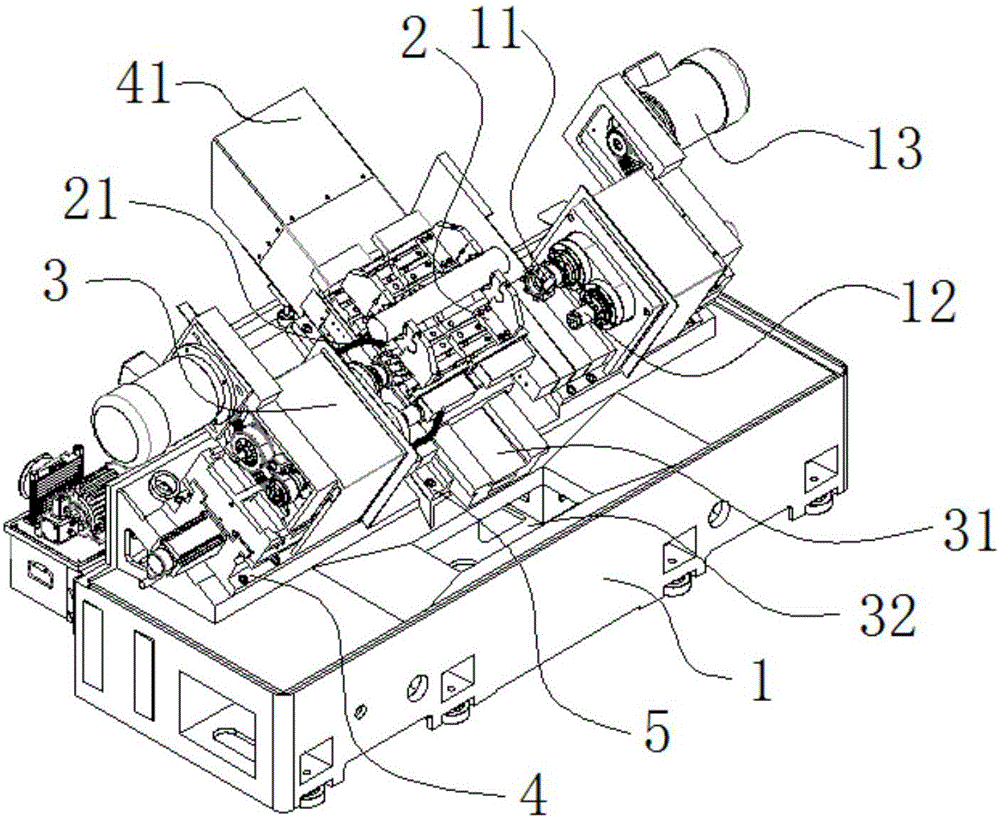

[0016] As shown in the figure: an oblique milling end face drilling center hole machine tool, including a bed 1, a clamping body 2, a power head 3, an end numerical control sliding table 4 and a middle numerical control sliding table 5, the end numerical control sliding table 4 There are two, symmetrically arranged on both sides of the central numerical control sliding table 5, the upper surfaces of the end numerical control sliding table 4 and the middle numerical control sliding table 5 are arranged obliquely, one end is high and the other is low, and they are respectively fixed above the bed 1. The power heads 3 are symmetrically installed on the end numerical control sliding table 4 and can be adjusted in horizontal feed. The clamp body 2 is installed on the middle numerical control sliding table 5 and can be adjusted in longitudinal feed. E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap