Single-cutting-edge disk slitting blade

A disc cutting and blade technology, which is applied in the field of tool manufacturing, can solve the problems of low service life and low manufacturing cost, and achieve the effects of low pollution, convenient installation and operation, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

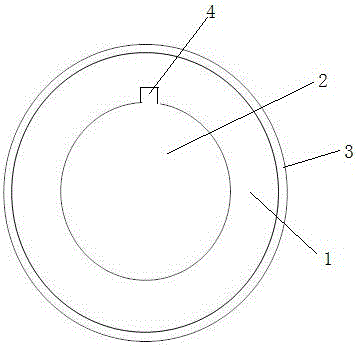

[0018] Example: such as figure 1 As shown, a single-edge disc slitting blade includes a disc-shaped blade body 1 made of tungsten steel alloy material. The middle part of the blade body 1 is provided with a circular hole 2 concentric with the blade body 1. The circular hole 2 A square notch 4 is provided on the edge, and blades 3 are provided on both sides of the edge of the blade body 1 .

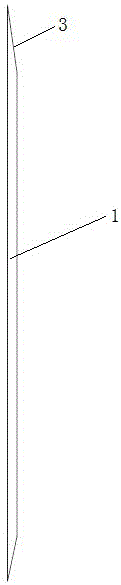

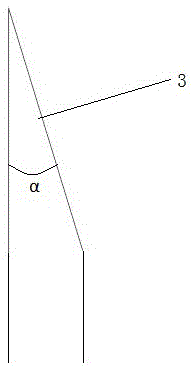

[0019] Such as figure 2 and image 3 As shown, the diameter of the blade body 1 is 130 mm, the diameter of the round hole 2 is 88 mm, the thickness of the blade body 1 is between 0.995-1.005 mm, and the included angle α of the blade portion 3 is 30°.

[0020] In the present embodiment, the density of the tungsten steel alloy material used to manufacture the blade body 1 is 14.6g / cm 3 , the hardness is HRC74.5-75, the bending strength is 2900-3200N / MM 2 , cobalt magnetic 11.7%, particle diameter 0.6-0.8um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com