Production line for preparing used-tire fine rubber powder

A technology for waste tires and production lines, applied in the field of resource recycling and comprehensive utilization, can solve the problems of declining quality indicators, increasing energy consumption, and reducing rubber performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

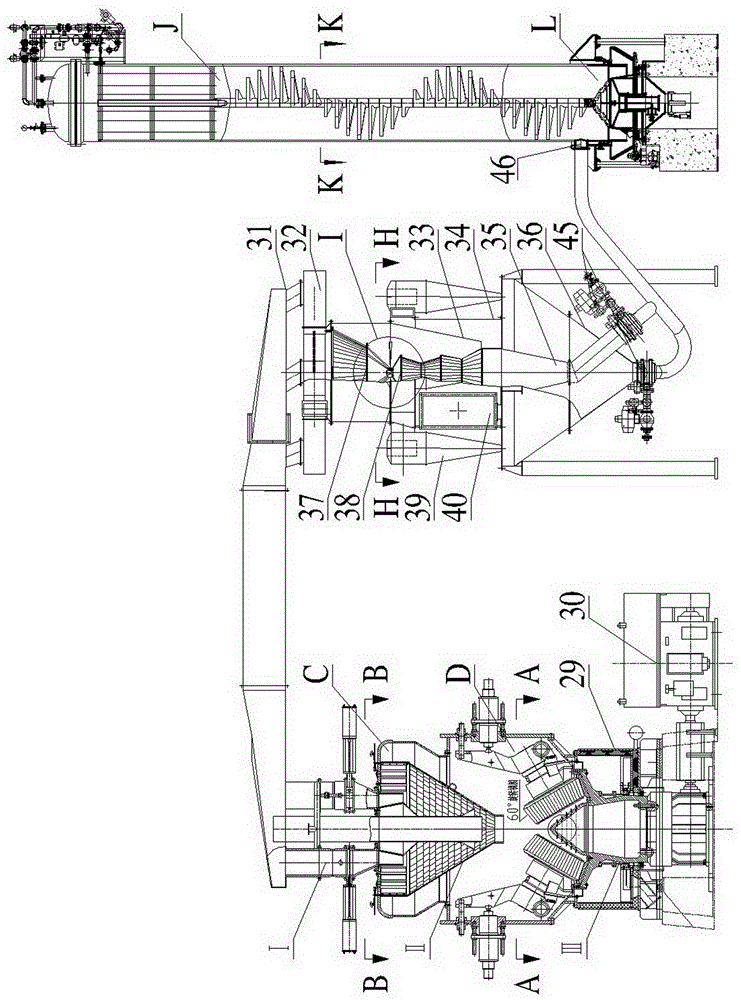

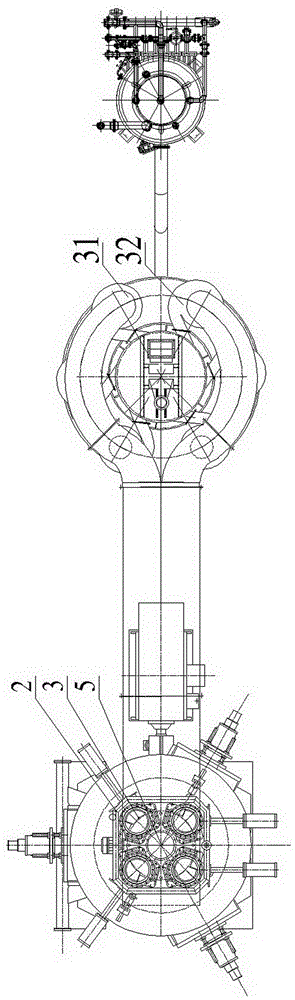

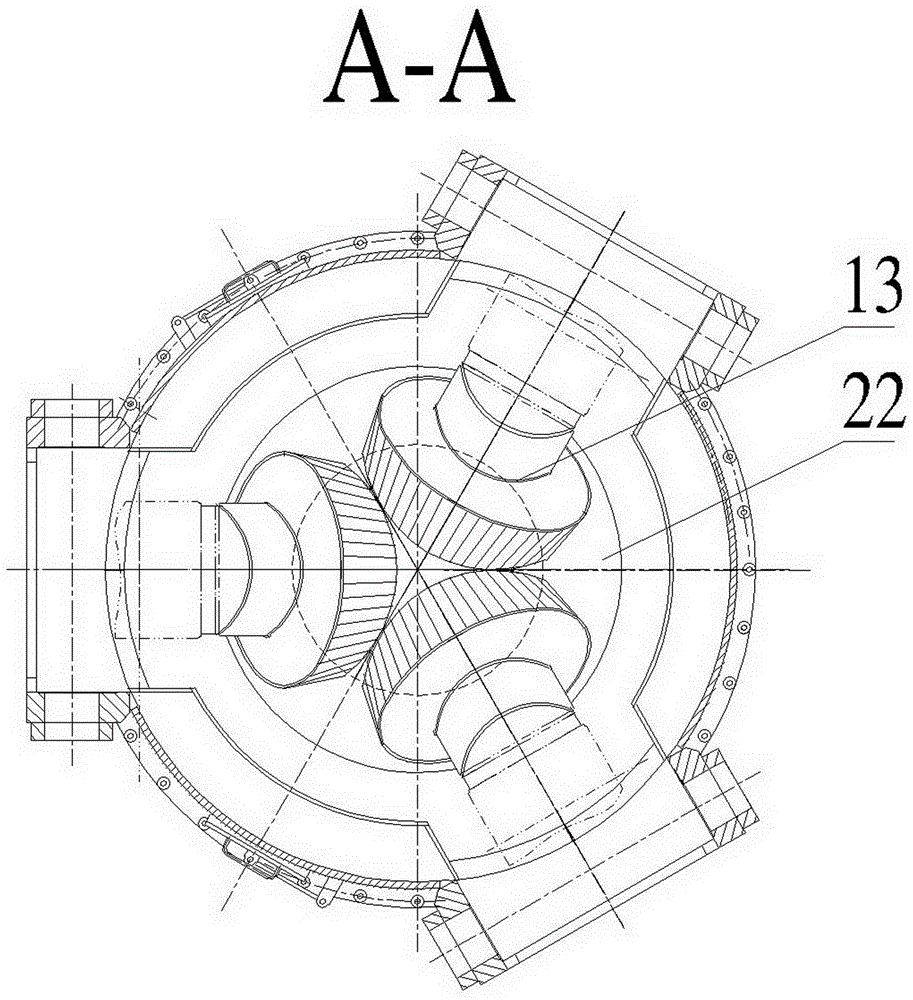

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, a production line for preparing waste tire fine rubber powder is characterized by: including distribution tank assembly I, separator assembly II, grinding assembly III, classifier assembly IV, air box pulse bag collection assembly V, spiral step blade separation Component VI, turntable component VII.

[0057] The distribution tank assembly I, separator assembly II, grinding assembly III, classifier assembly IV, air box pulse bag collection assembly V, spiral step blade separation assembly VI, and turntable assembly VII are connected in sequence.

[0058] The distribution tank assembly I includes a header 1 , an annular header 2 , a Venturi ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com