A sorting device for fine rubber powder finished products of waste tires

A technology for waste tires and sorting devices, which is applied in the field of resource recycling and comprehensive utilization, and can solve the environmental protection problems of rubber powder accumulations that are not easy to dissipate heat and spontaneous combustion of rubber powder products at room temperature, the mesh size of the screen reduces the screening efficiency, and the screen mesh effectively sieves Problems such as limited sub-area, to achieve the effect of inhibiting reproduction and growth, preventing combustion or even deflagration, and solving storage spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

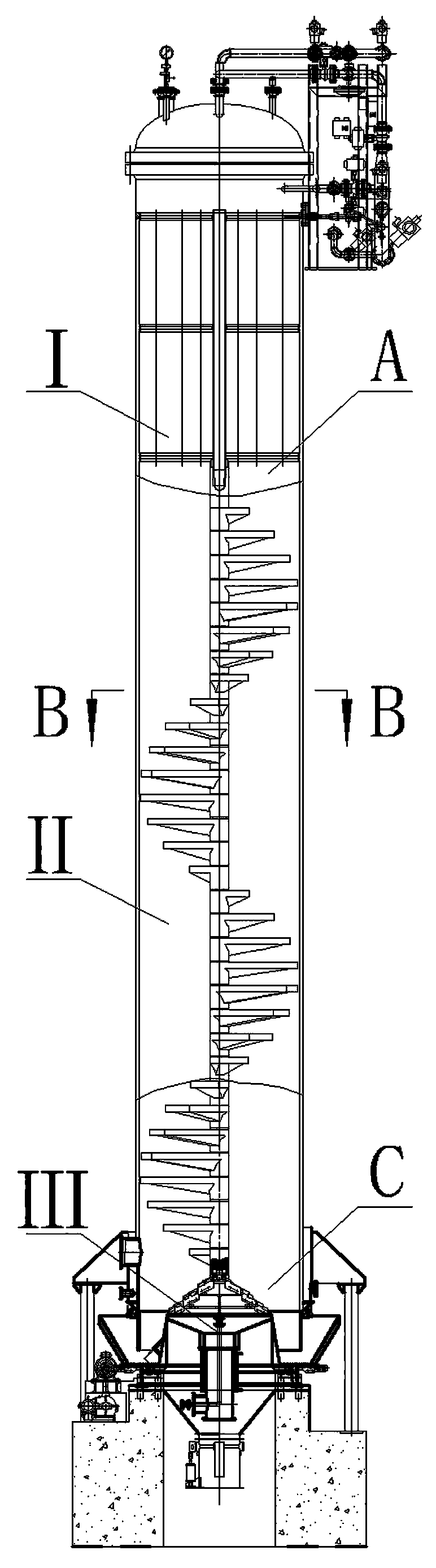

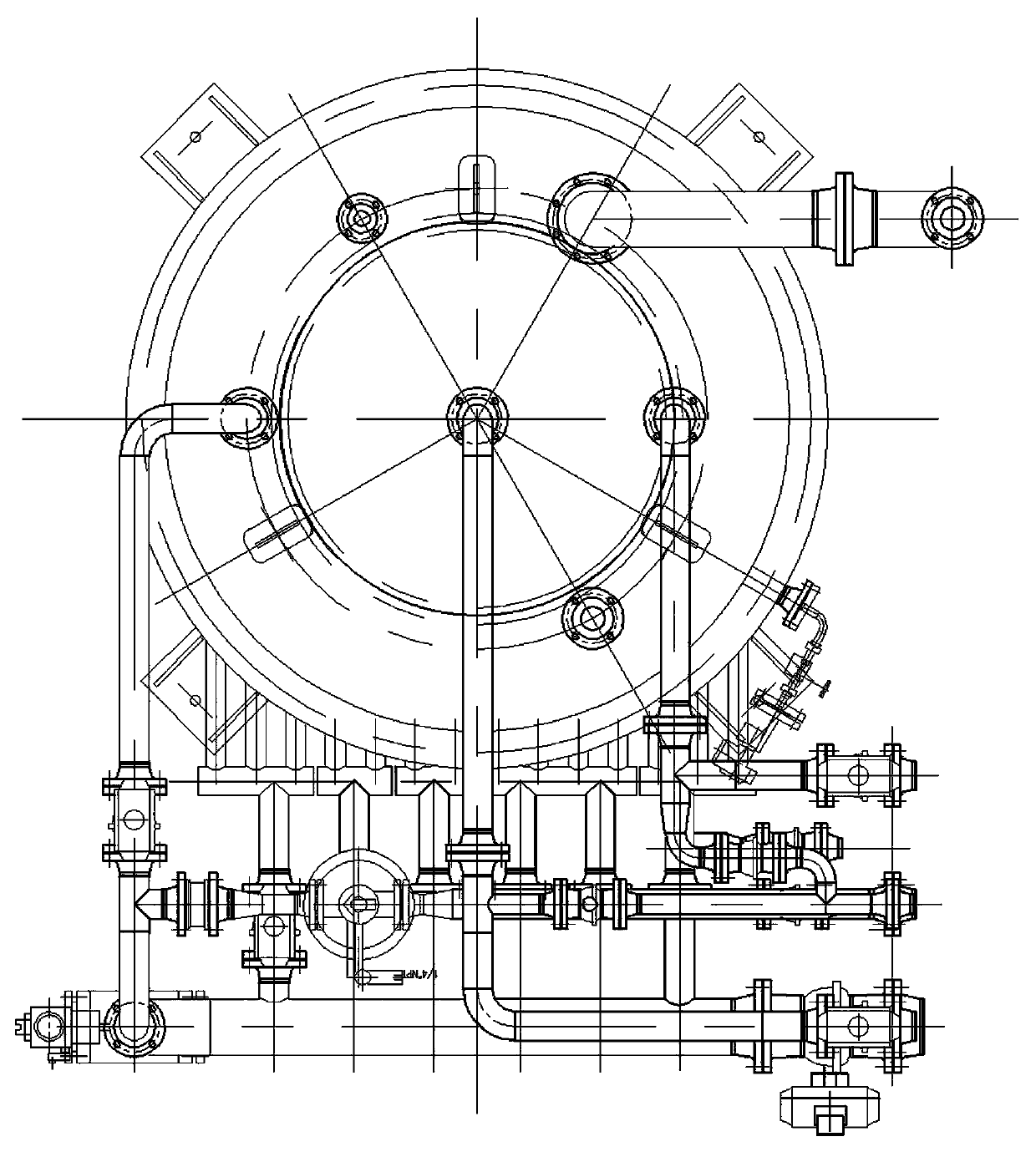

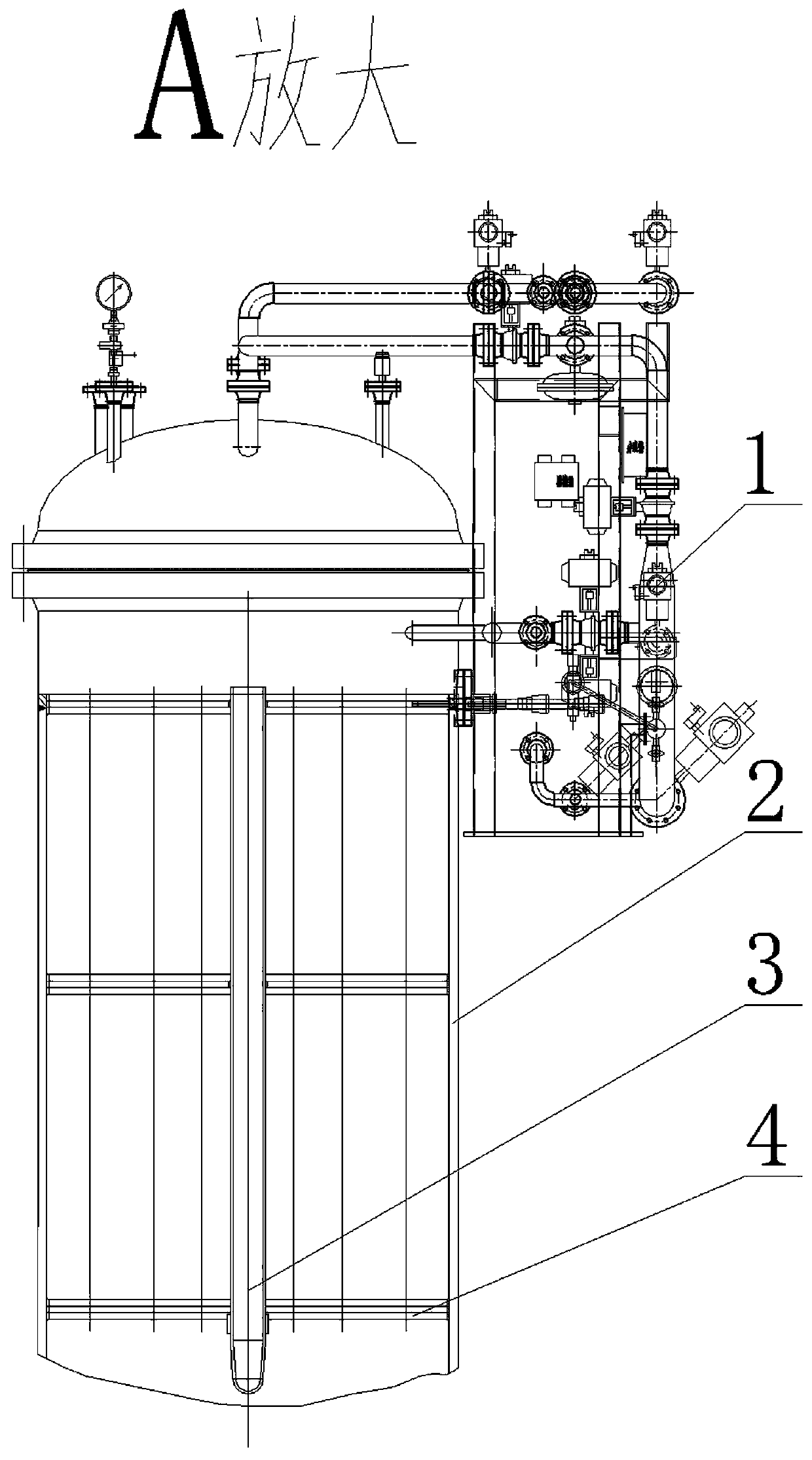

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a waste tire fine rubber powder finishing device is characterized in that it includes an air box pulse bag collection assembly I, a spiral stepped blade separation assembly II, and a turntable assembly III.

[0026] The air box pulse bag collection assembly I, the spiral step blade separation assembly II, and the turntable assembly III are connected in sequence.

[0027] The air box pulse bag collection assembly I includes a pulse exhaust blowback control system 1 , a box body 2 , a filter bag group 3 , and a flower plate 4 . The flower plate 4 is fixed in the box body 2, and the filter bag group 3 is fixed in place sequentially in the holes of the flower plate 4, and the pulse exhaust blowback control system 1 controls the exhaust and blowback ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com