Hot melt adhesive as well as preparation method and application thereof

A technology for hot melt adhesive and reaction vessel, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor high temperature resistance, unpleasant odor, etc., and achieve the effect of excellent high temperature resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to the preparation method of the second aspect, for preparing the hot melt adhesive described in the first aspect, the preparation method comprises the following steps:

[0029] S1: Accurately weigh each component;

[0030] S2: Add the wax into a reaction vessel, set the temperature to 150°C, start heating; set the initial stirring speed to 30 rpm, start stirring, increase by 20 rpm every 10 minutes until it reaches 60 rpm Minutes, keep stirring until the wax is completely melted;

[0031] S3: Add APAO, tackifying resin and 2 / 3 quality antioxidant into the reaction vessel, and stir at a stirring speed of 30 rpm;

[0032] S4: vacuumize the reaction vessel, and fill it with nitrogen until the vacuum degree in the reaction vessel is 0.08Mpa;

[0033] S5: When the temperature of the reaction material reaches 128-132°C, add the remaining 1 / 3 mass of antioxidant into the reaction vessel, open the pipeline and heat for 30 minutes;

[0034] S6: Turn off the pipelin...

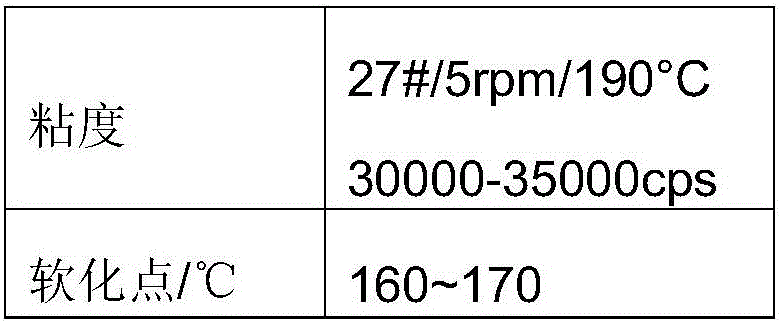

Embodiment 1

[0038] According to this embodiment, a high-temperature-resistant and odorless hot-melt adhesive for automobiles consists of the following components: 64Kg APAO, 5Kg polyethylene wax, 30Kg hydrogenated petroleum tackifying resin and 1Kg multi-component hindered phenolic macromolecular antioxidant.

[0039] Prepare the hot melt adhesive for automobiles according to the following steps:

[0040] S1: Accurately weigh each component;

[0041] S2: Add polyethylene wax into a stirred tank, set the temperature to 150°C, start heating; set the initial stirring speed to 30 rpm, start stirring, increase by 20 rpm every 10 minutes until it reaches 60 rpm Minutes, keep stirring until the polyethylene wax is completely melted;

[0042] S3: Add APAO, tackifying resin and 2 / 3 mass multi-component hindered phenolic macromolecular antioxidant into the stirring tank, and stir at a stirring speed of 30 rpm;

[0043] S4: vacuumize the stirred tank, and adjust the nitrogen valve according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com