Multi-section compaction-type sleeve valve pipe and grouting method thereof

A technology of sleeve valve pipe and grouting, which is applied in the field of multi-stage compacted sleeve valve pipe and its grouting, can solve the problems of tunnel secondary diseases, slurry leakage and leakage, and inability to form continuous grouting body, etc., to avoid Effects of secondary diseases, avoiding pulping, and reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

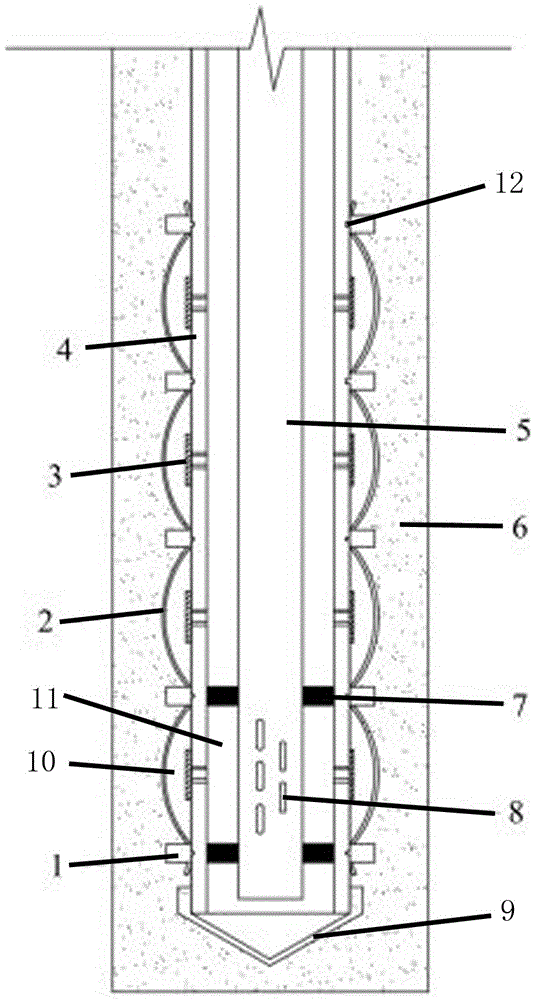

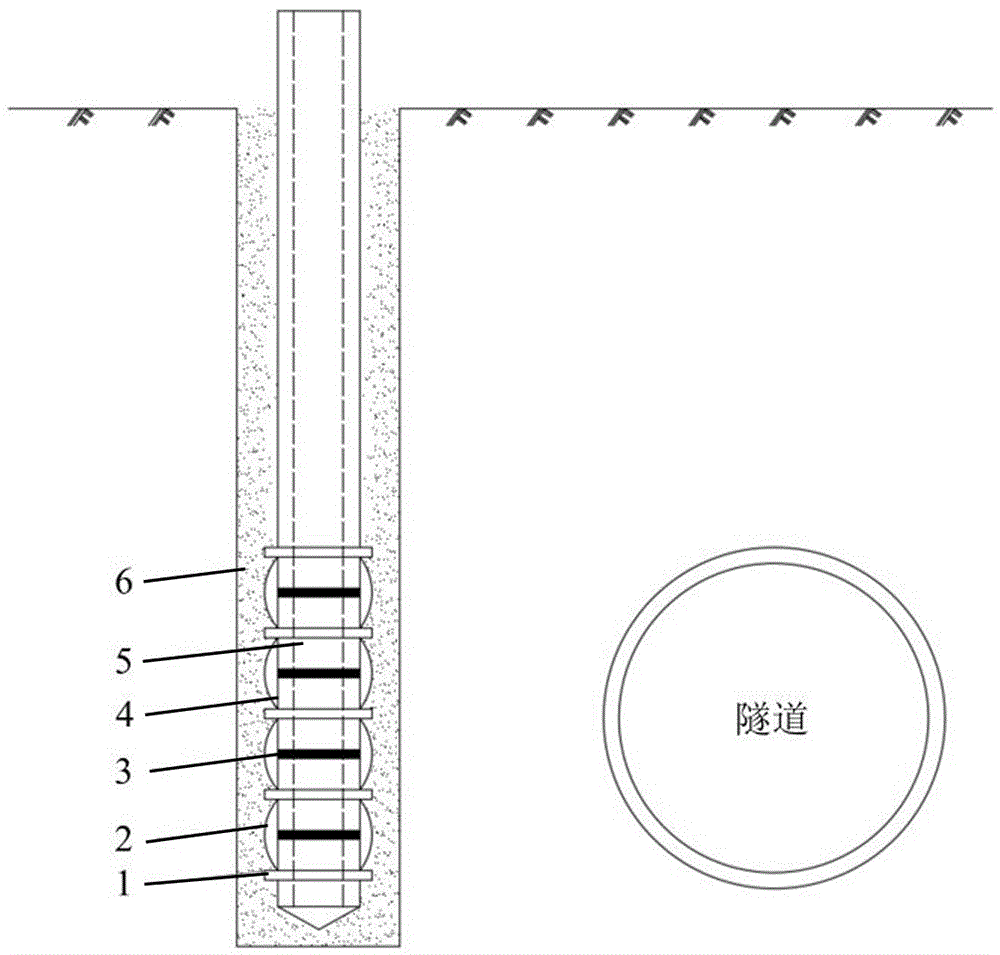

[0027] Such as figure 1 As shown, the present embodiment is a multi-section compact sleeve valve tube, which can be used to control the deformation of the built tunnel. Slurry inner tube 5.

[0028] In this example, the lower part of the outer pipe 4 is a grouting section, and the grouting section of the outer pipe is evenly provided with 4 rubber valves 3 connecting the inside and outside of the outer pipe; the outer pipe 4 is covered with a geotextile cover 2 corresponding to the grouting section, and The sleeve is fixed on the outer pipe in sections according to the length of 1.0 m through five fixing rings 1 , and the geotextile sleeve 2 and the outer pipe 4 are separated by the fixing rings 1 to form four chambers 10 . Among them, the sum of the volumes of the chambers 10 between the geotextile cover 2 and the outer pipe 4 is 0.6 to 0.9 times the designed grouting volume, and the tensile strength of the geotextile cover 2 is greater than 15 kN / m; the outer wall of the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com