Permanent magnet servo motor

A permanent magnet servo motor and yoke technology, which is applied to synchronous motors, magnetic circuits, and electric components with static armatures and rotating magnets, which can solve the adverse effects of motor power density, reduce labor productivity, and reduce the amount of permanent magnets. Limitations and other issues, to achieve the effects of excellent corrosion resistance, reduced hysteresis loss, and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

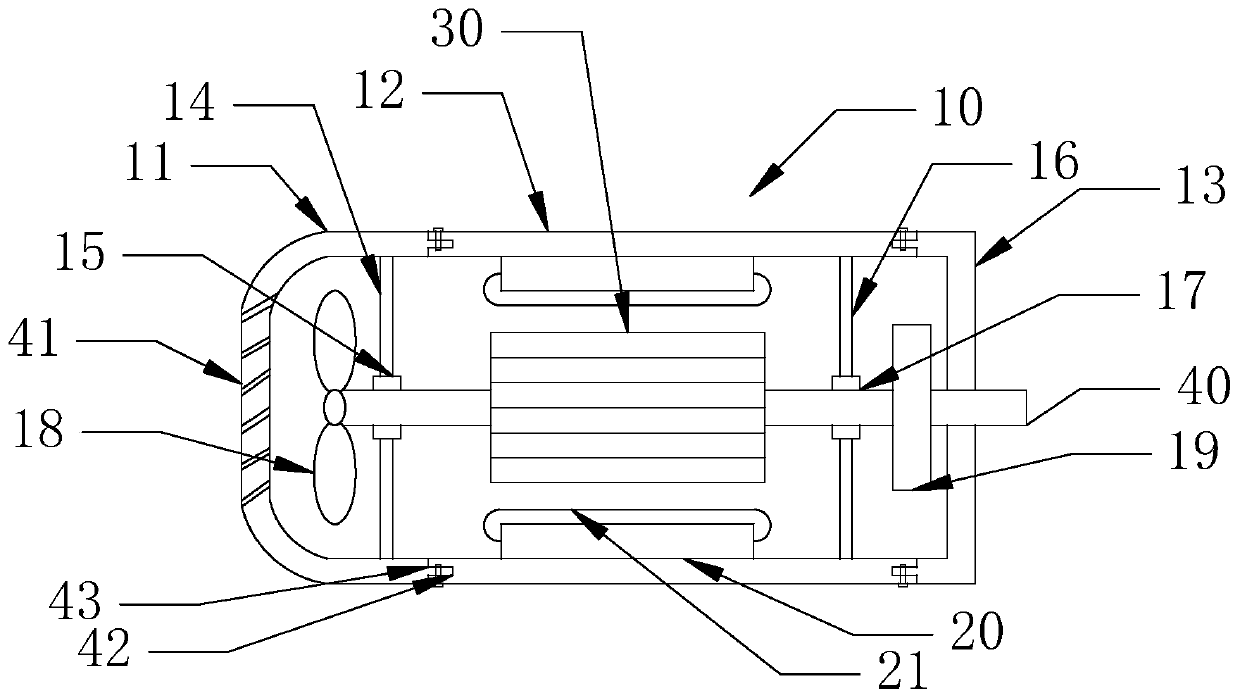

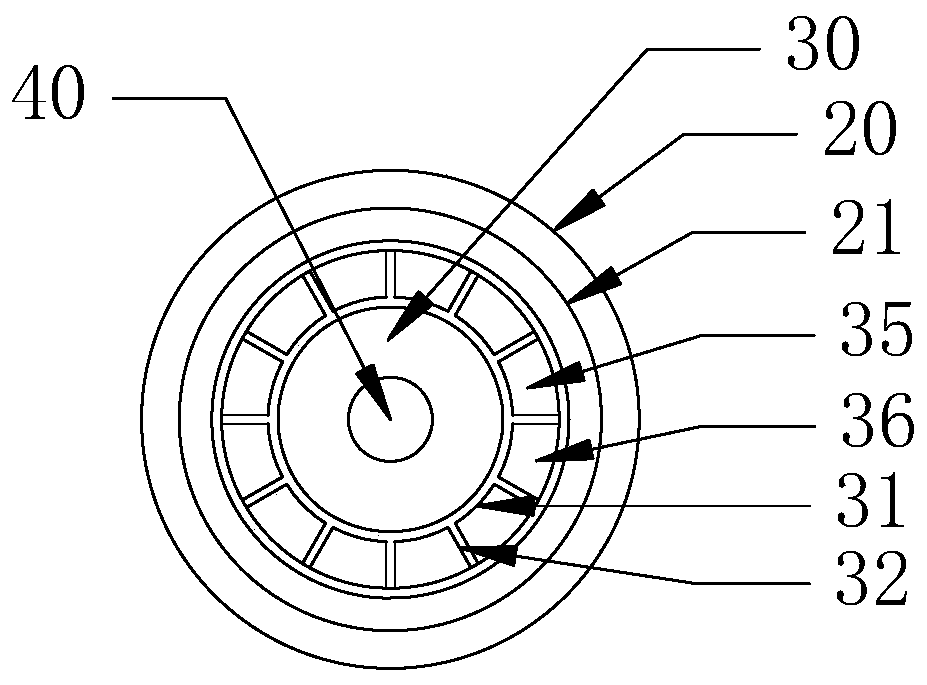

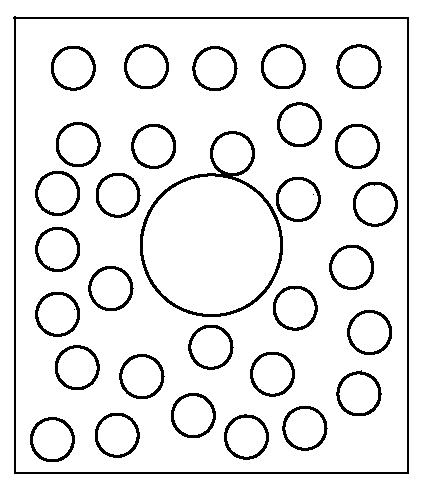

[0022] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments. In the following description, characteristic details such as specific configurations and components are provided only to help a comprehensive understanding of the embodiments of the present invention. Accordingly, those of ordinary skill in the art should recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted for clarity and conciseness.

[0023] It should be understood that reference throughout this specification to "one embodiment" or "an embodiment" means that a particular feature, structure, or characteristic related to the embodiment is included in at least one embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com