Novel efficient pulverized coal combustion device

A high-efficiency technology for pulverized coal combustion, applied in the combustion method, combustion control, combustion equipment and other directions, can solve the problems of unreasonable ventilation layout, partial flame, multiple ignition, etc. Effects of large swirl duct air volume, expanded diameter and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

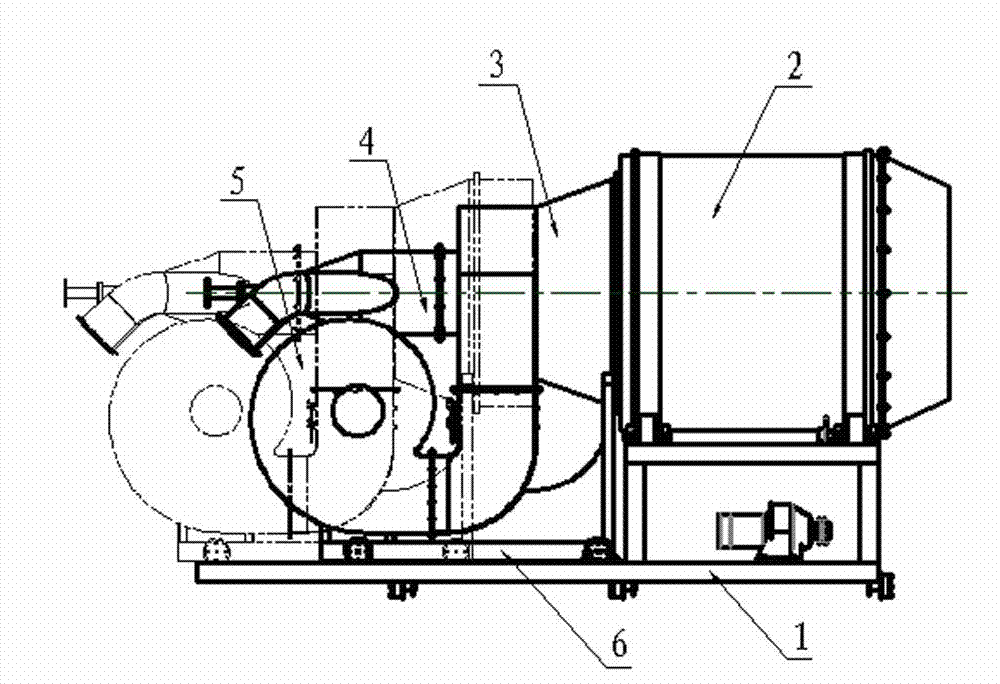

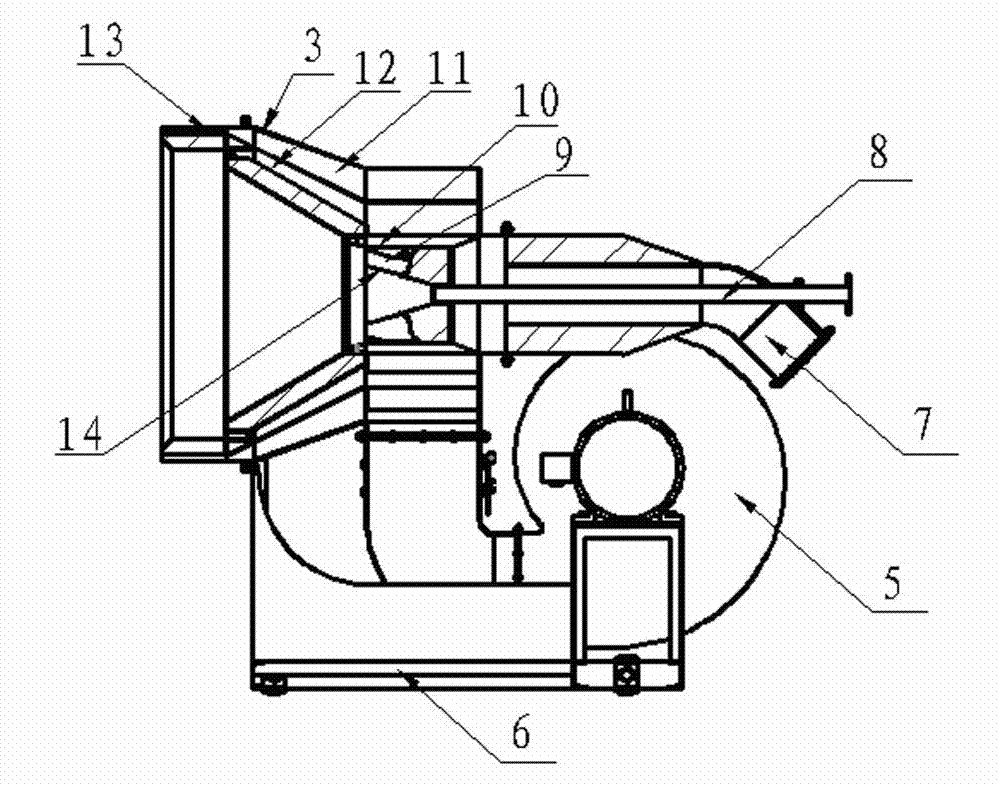

[0012] Such as figure 1 The new high-efficiency pulverized coal combustion device shown has a bottom frame 1, a furnace 2, a stable combustion chamber 3, an air powder adjustment mechanism 4, a fan 5, an ignition device and an electrical control system. The furnace 2 is placed on the bottom frame 1, and the stable combustion A part of the chamber 3 is embedded in the furnace body, and the stable combustion chamber 3 is connected with the wind powder regulating mechanism 4 and the ignition device. Such as figure 2 The air powder regulating mechanism 4 shown is provided with an outer DC air duct 11, a swirling air duct 12, an inner DC air duct 10, a pulverized coal air duct 7, and a central pipe 8 from the outer layer inward, and the fan 5 is connected to the outer DC air duct. 11. The swirl air channel 12 communicates with the inner direct air channel 10 . The outlet end of the outer DC air duct 11 is provided with long-distance DC blades 13, and the swirl air duct is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com