A light-weight force transmission strut structure and casing with the strut structure

A light-weight, supporting plate technology, applied in the direction of mechanical equipment, machine/engine, gas turbine device, etc., can solve the problems of high processing cost, blank raw material loss, blank loss, etc., to improve engine performance, increase structural strength, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

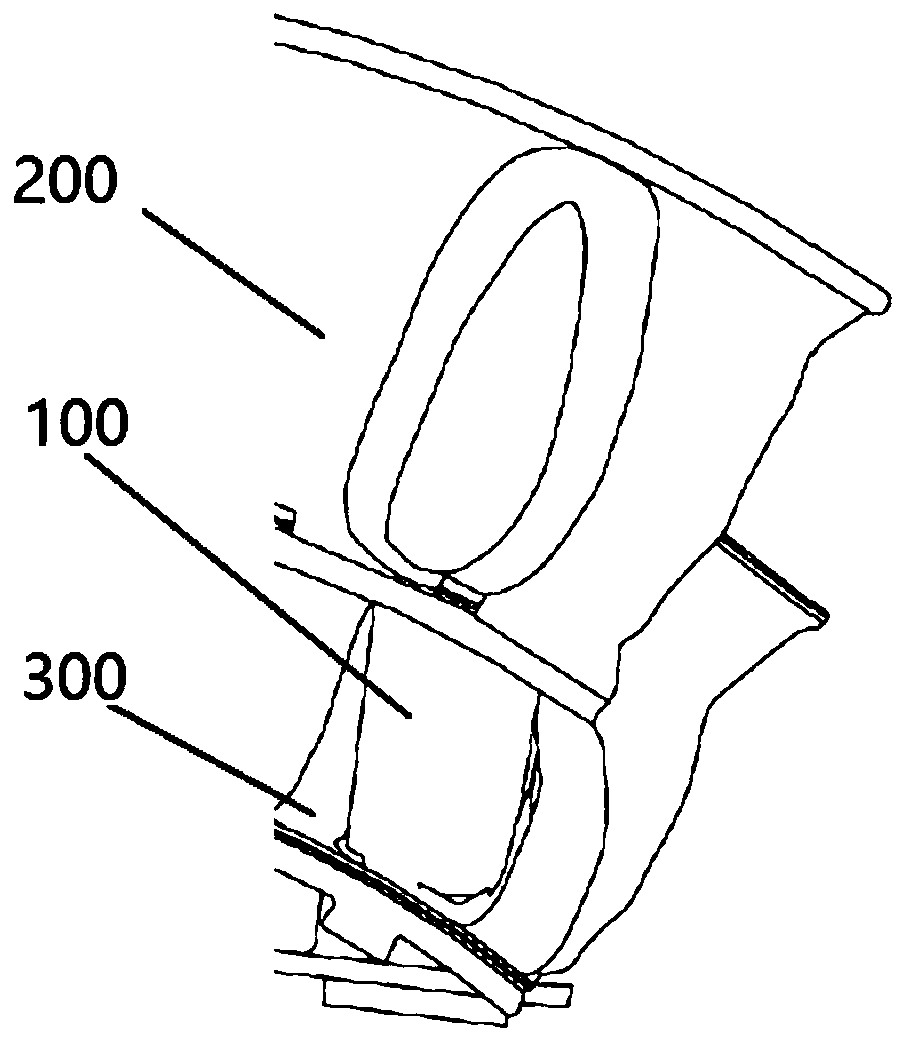

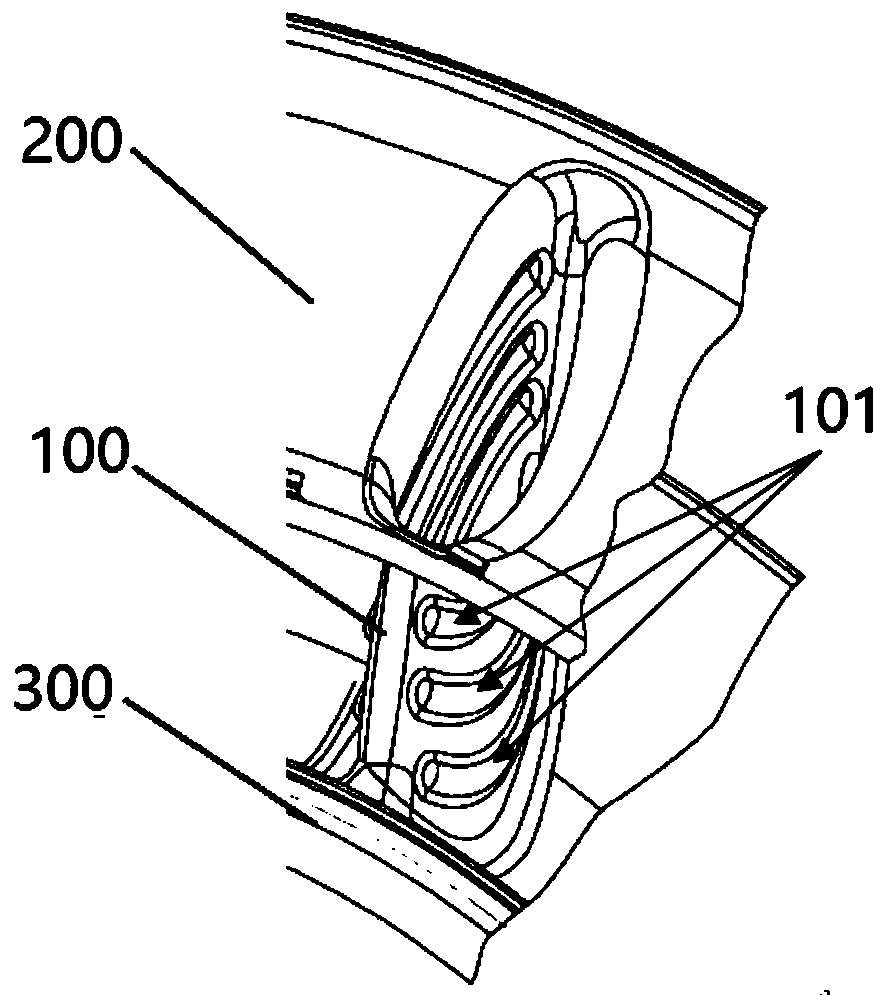

[0024] figure 2 It is the lightweight force transmission strut structure of the present invention. The light-weight force transmission strut structure 100 of the present invention is arranged between the inner ring casing 200 and the outer ring casing 300 of the engine. The lower end is welded on the outer wall of the inner ring casing 200 . figure 2 It shows that the lightweight force transmission strut structure of the present invention is applied in the high and low pressure turbine stage transition section of the aeroengine, and plays the role of transmitting the radial load of the high pressure rear fulcrum bearing. The force transmission support plate 100 is formed by thin-walled plates through sheet metal, and has the airfoil shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com