Full-automatic AOI particle indentation detection machine

A fully automatic, testing machine technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of difficult to ensure 100% qualified rate of finished products in the production line, decrease in product pass-through rate, waste of labor by manufacturers, etc. Improved camera resolution and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

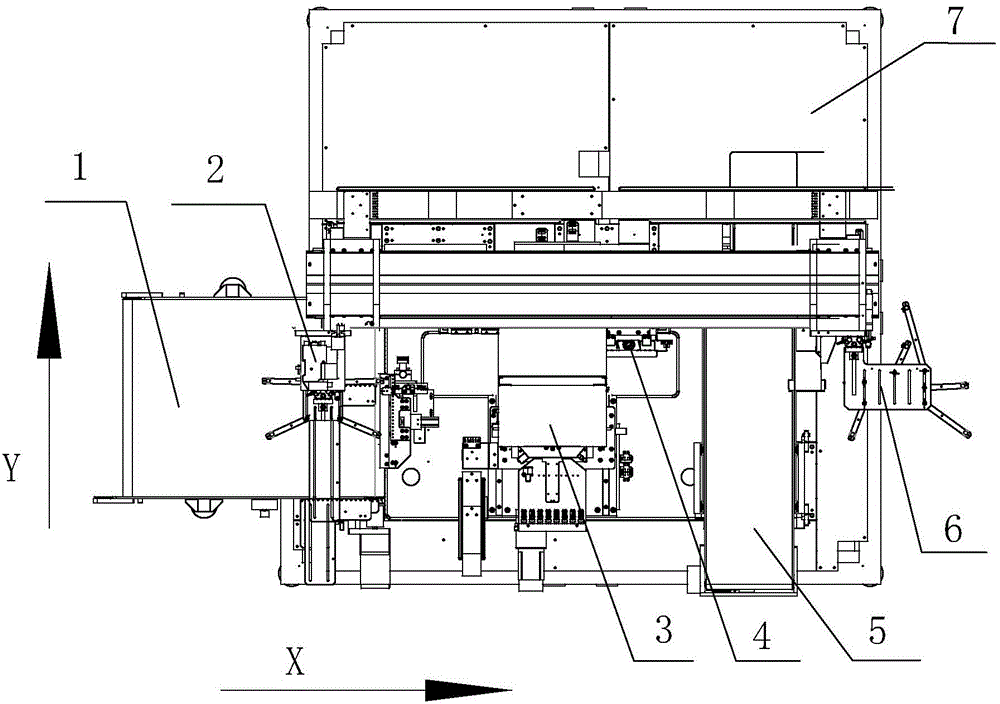

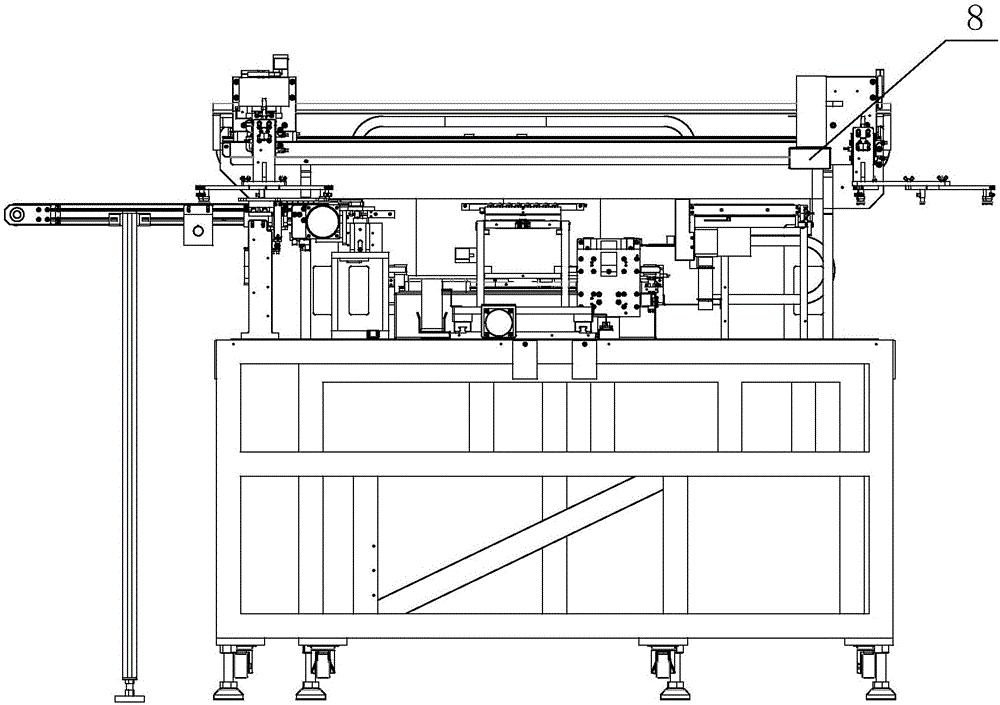

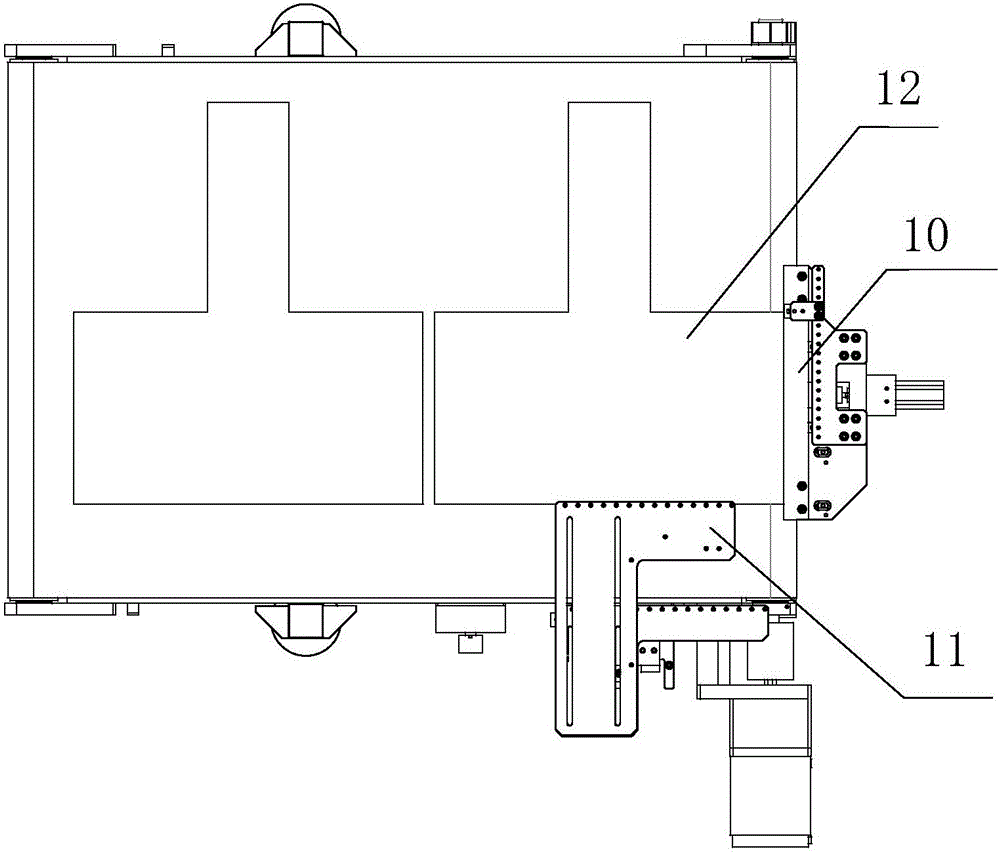

[0026] The invention provides a fully automatic AOI particle indentation detection machine, which includes a particle indentation detection unit for detecting LCM bound with an IC, and the particle indentation detection unit is equipped with an independent IC chipping edge chipping detection camera (8 );

[0027] When the particle indentation detection unit performs indentation detection on the LCM, the IC chipping edge and chipping detection camera (8) detects IC chipping corner chipping and edge chipping on the IC bound on the LCM;

[0028] The IC chipping edge chipping detection method comprises:

[0029] S1) When the particle indentation detection unit performs indentation detection on the LCM, the chipping corner and edge chipping detection camera (8) moves above the IC bound on the LCM to take pictures, and obtains the IC image;

[0030] S2) After binarizing the IC image acquired in the step S1, an IC outline image showing the IC outline is obtained;

[0031] S3) Compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com