Device and method for increasing circuit board wiring density

A line density and circuit board technology is applied in the field of devices for increasing the wiring density of the circuit board, which can solve the problems of reducing the wiring density of the circuit board, etc., and achieve the effects of improving the timing accuracy, speeding up the etching speed, and improving the degree of refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

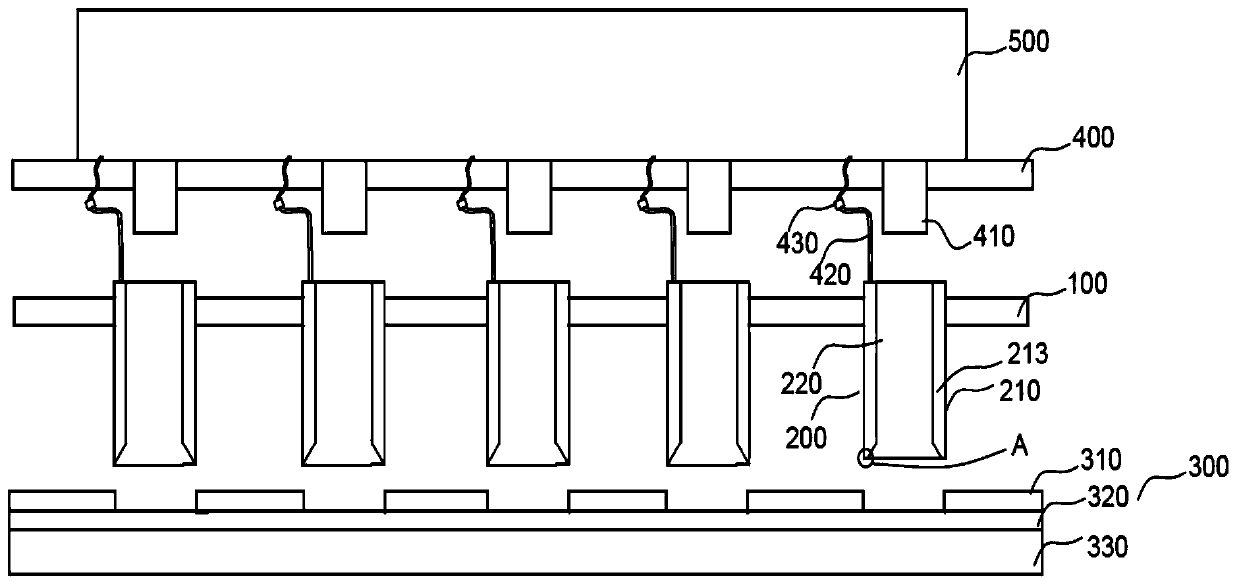

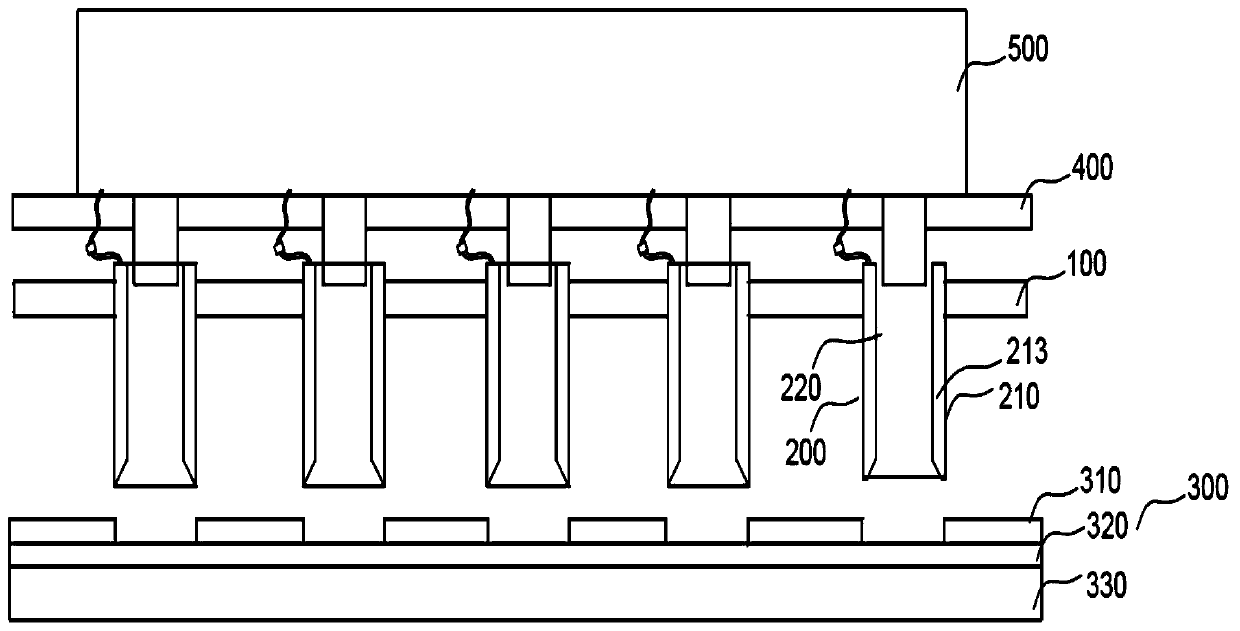

[0042] The invention provides a device and a method for increasing the wiring density of a circuit board, such as Figure 1-5 As shown, it includes a mask plate, a pressing plate 100, a protective sleeve 200 and a moving plate 400, wherein the mask plate is movably arranged on the upper end of the circuit board 300 to be etched, and is used for masking the photoresist on the circuit board 300 , the mask plate is provided with a number of through holes, after masking, exposure, and development, the photoresist 310 in the corresponding area of the through holes is removed to expose the conductor part to be etched, and then the exposed conductor is etched , the remaining conductor is the conductive line.

[0043] The pressing plate 100 is movably arranged on the upper end of the mask, and after the mask is completed, the mask can be removed, and the mask can be kept in place.

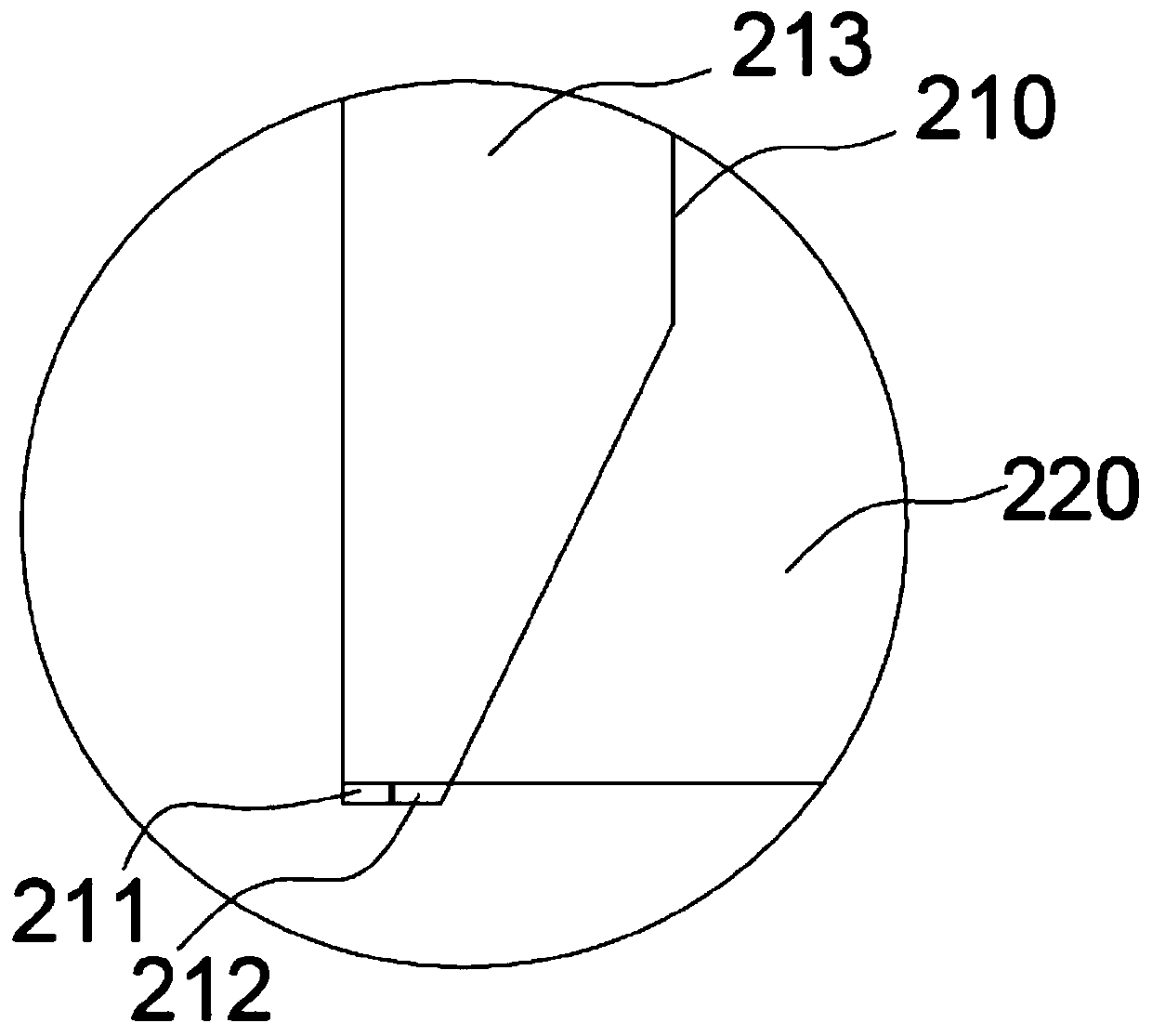

[0044] The protective sleeve 200 is a cylindrical structure whose cross-section is consistent with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com