Robot teaching method and robot

A teaching method and robot technology, applied in the direction of robots, instruments, manipulators, etc., can solve the problem of not being able to specify the position of the image sensor beam direction, and achieve the effect of improving the teaching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] (first embodiment)

[0037] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings. Hereinafter, the same reference numerals are attached to the same or corresponding elements in all the drawings, and repeated explanations are omitted.

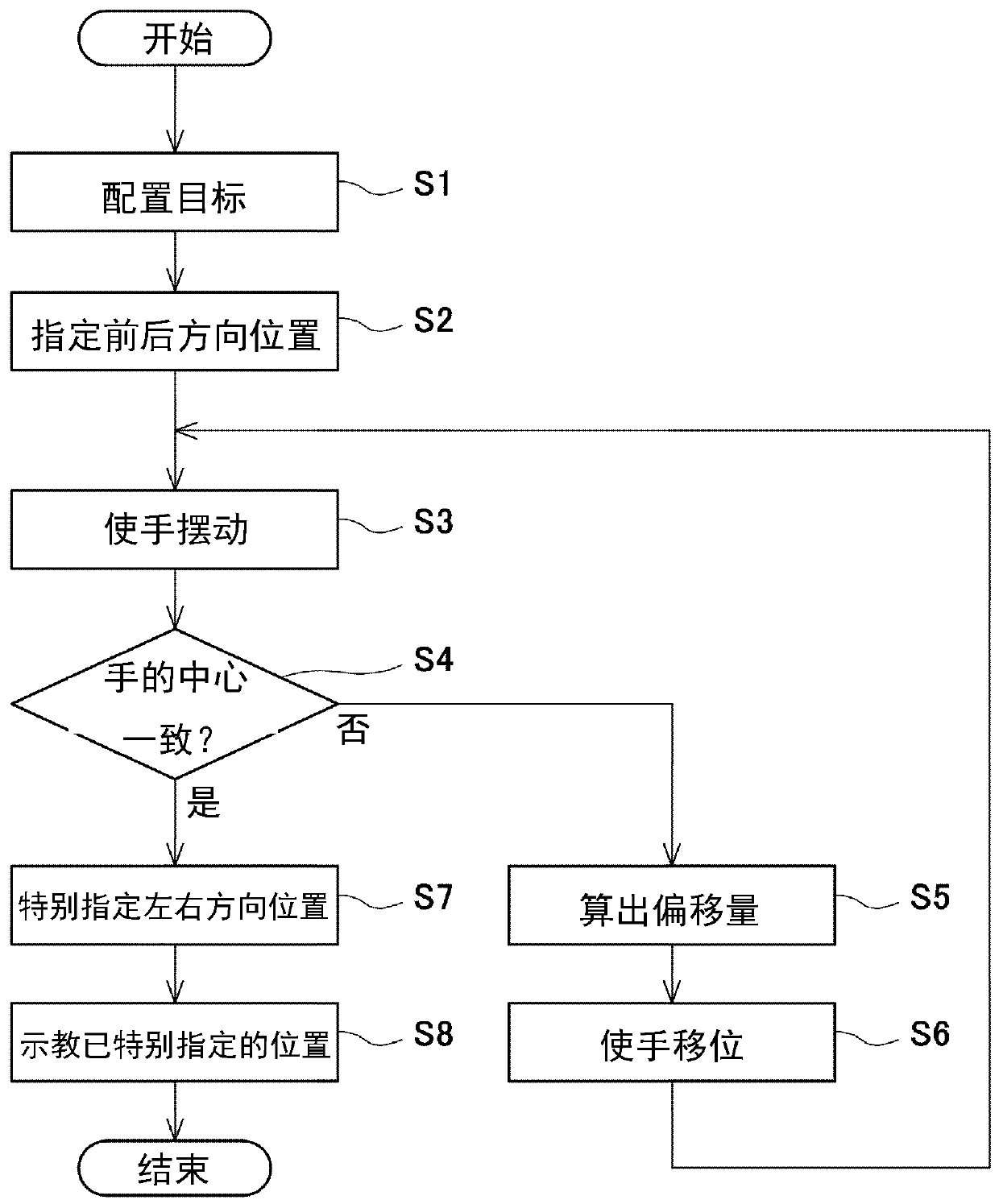

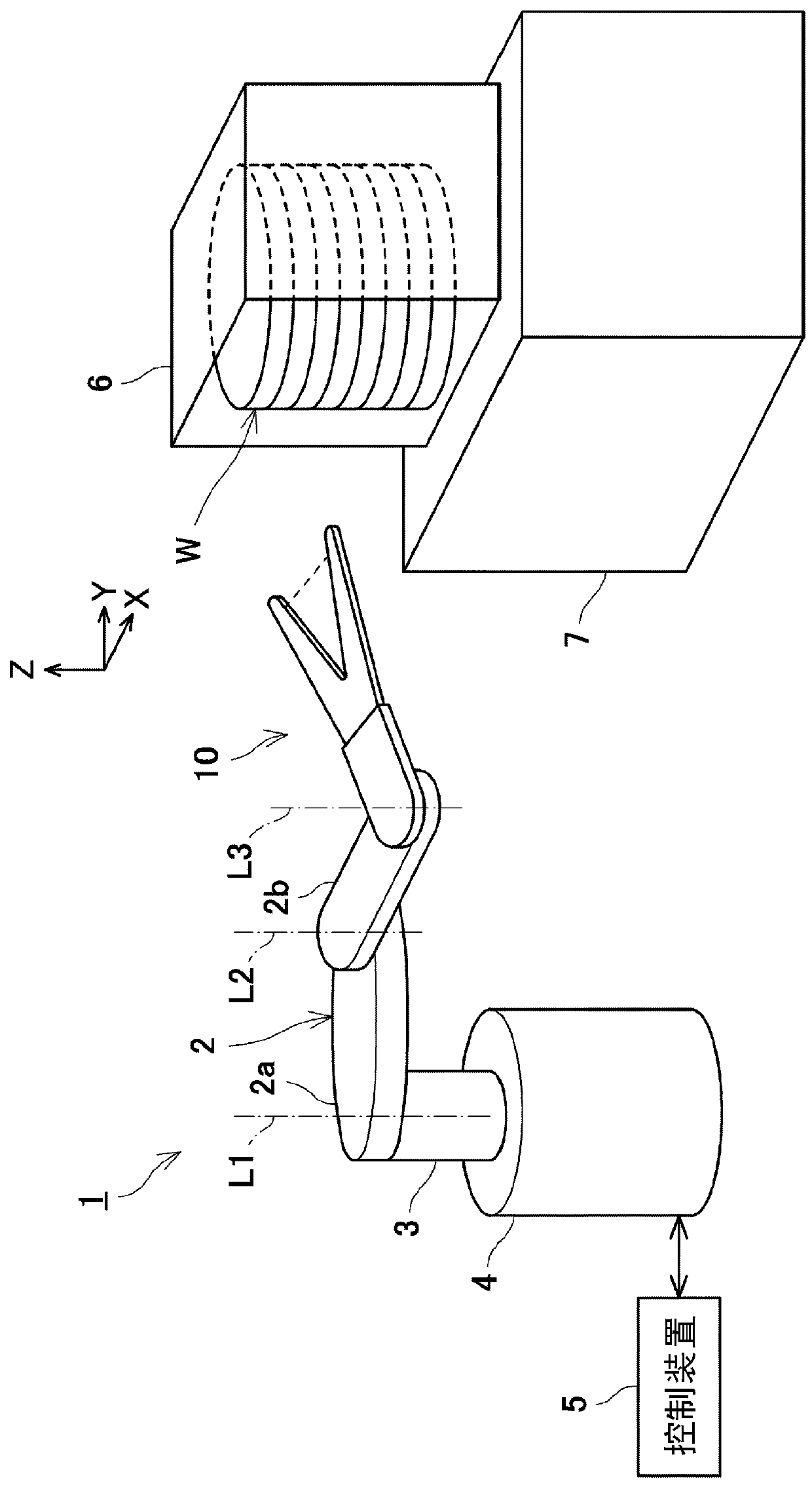

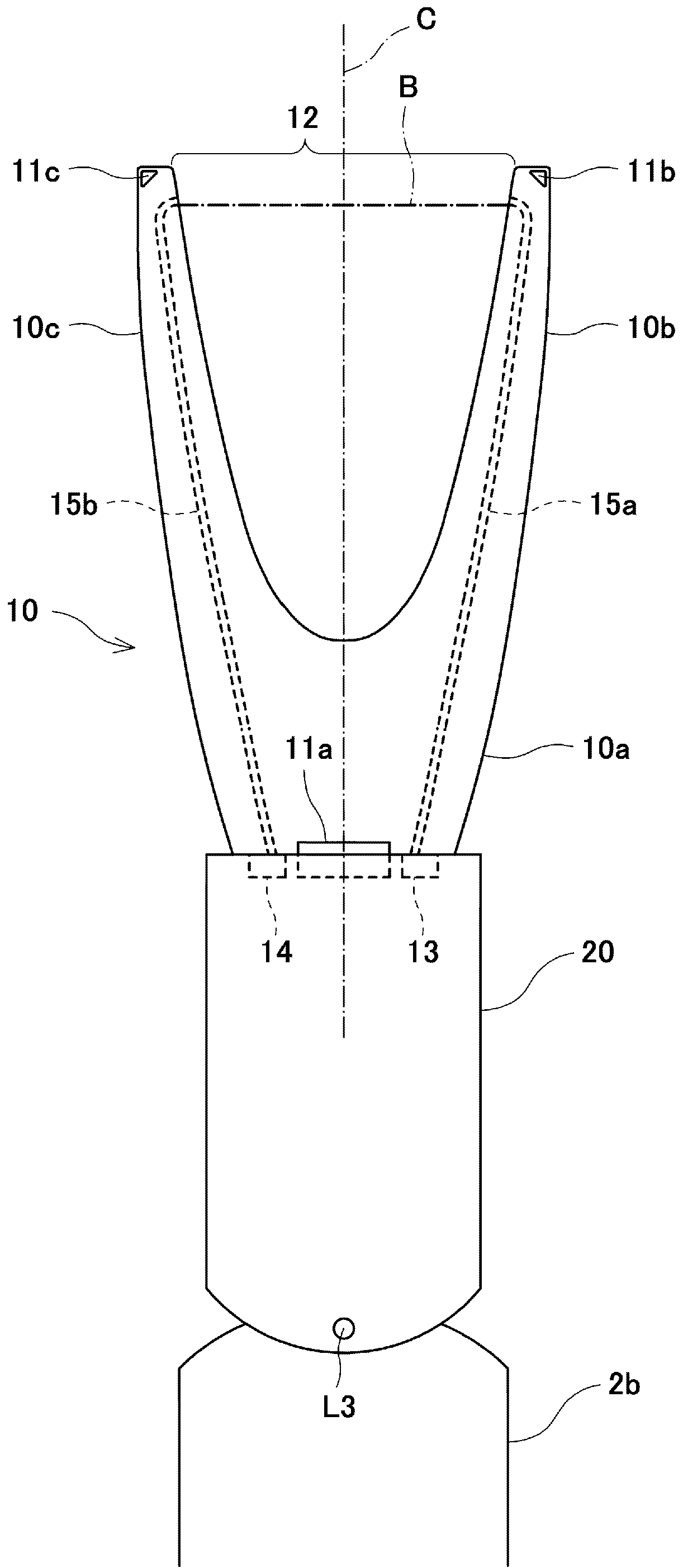

[0038] figure 1 It is a schematic diagram showing the structure of the robot 1 of the first embodiment. Such as figure 1 As shown, the robot 1 is used, for example, to transport a substrate W such as a wafer, which is a material of a semiconductor package, in a semiconductor processing facility for manufacturing a semiconductor package. Wafers include semiconductor wafers and glass wafers. Semiconductor wafers include, for example, silicon wafers, wafers of other semiconductor monomers, and wafers of compound semiconductors. Glass wafers include, for example, glass substrates for FPDs, glass substrates for MEMS, and sapphire (single crystal alumina) wafers. A semiconductor process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com