Vegetable straw fertilizer-making, sorting and plastic-clearing device and implementation method thereof

A realization method and straw technology, which is applied in the field of vegetable straw fertilizer sorting and clearing system, can solve the problems that the product cannot meet the organic fertilizer standard, plastic waste cannot be removed at one time, soil pollution, etc., to meet the needs of technical equipment, realize Feasibility, the effect of ensuring the quality of organic fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

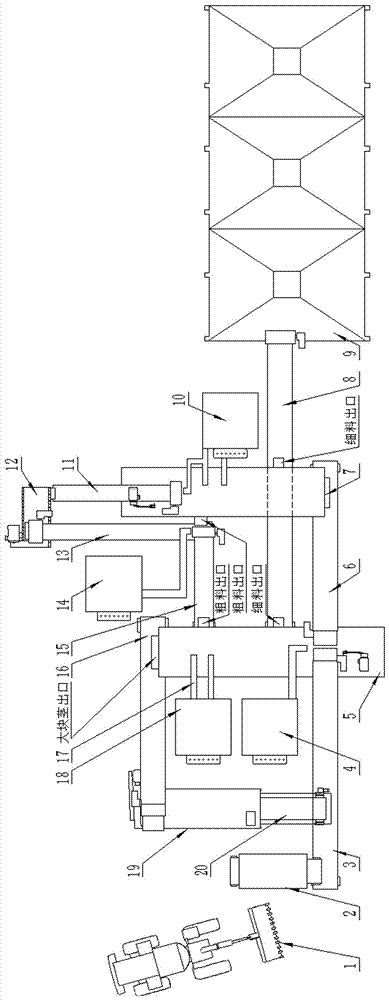

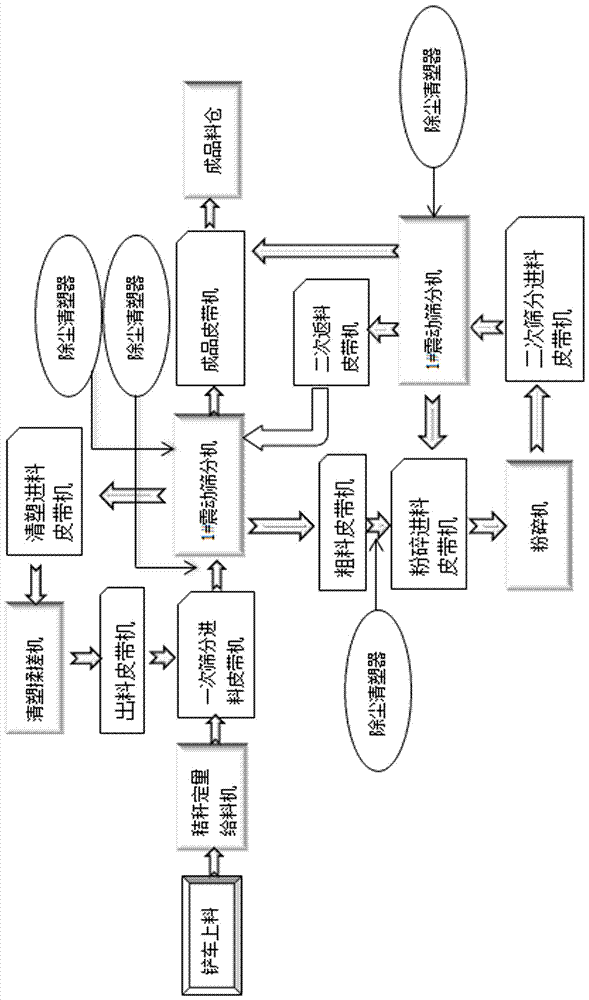

[0036] Examples such as figure 1 , figure 2 As shown, a vegetable straw fertilizer sorting and clearing system includes a loader 1, a straw quantitative feeder 2, a belt conveyor, a dust remover, a vibrating screen, a finished product bin 9, a pulverizer 12, and a pipeline 17. Plastic rubbing machine 19.

[0037] The straw quantitative feeder 2, after being loaded by the loader 1, realizes the quantitative feeding of materials through frequency conversion speed regulation.

[0038] Described belt conveyor comprises primary screening feeding belt conveyor 3, secondary feeding belt conveyor 6, finished product belt conveyor 8, secondary screening feeding belt conveyor 11, pulverizing feeding belt conveyor 13, coarse material belt conveyor 15, Plastic feed belt conveyor 16, discharge belt conveyor 20, belt conveyors are used to connect each link of the production line and transport materials.

[0039] The dust-removing and plastic-removing device comprises a first dust-removi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com