Manufacturing method of horizontal ultra-wide multicolored grain recombined decorative veneer

A technology for reorganizing decoration and manufacturing methods, which is applied in the joining of wooden veneers, manufacturing tools, chemical instruments and methods, etc., can solve the problems of manufacturing horizontal ultra-wide multi-color texture reorganized decorative veneers without a manufacturing method, etc. It is not easy to bend and deform, the bonding is firm, and the manufacturing process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

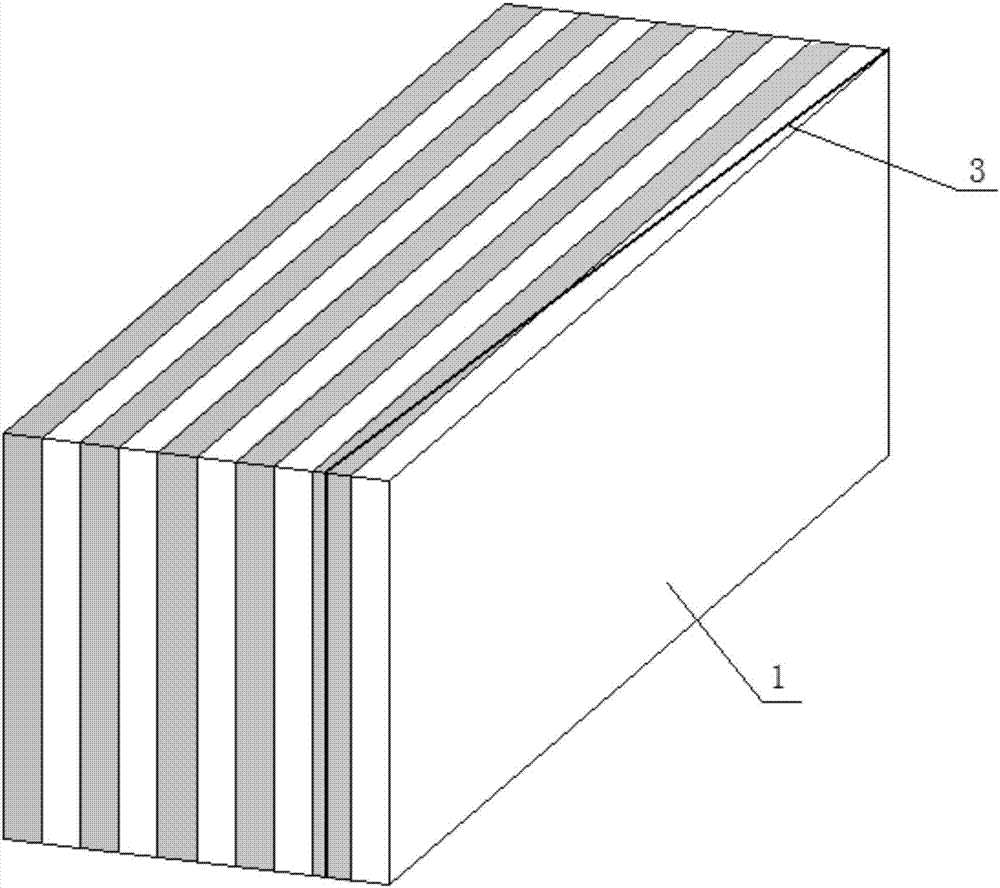

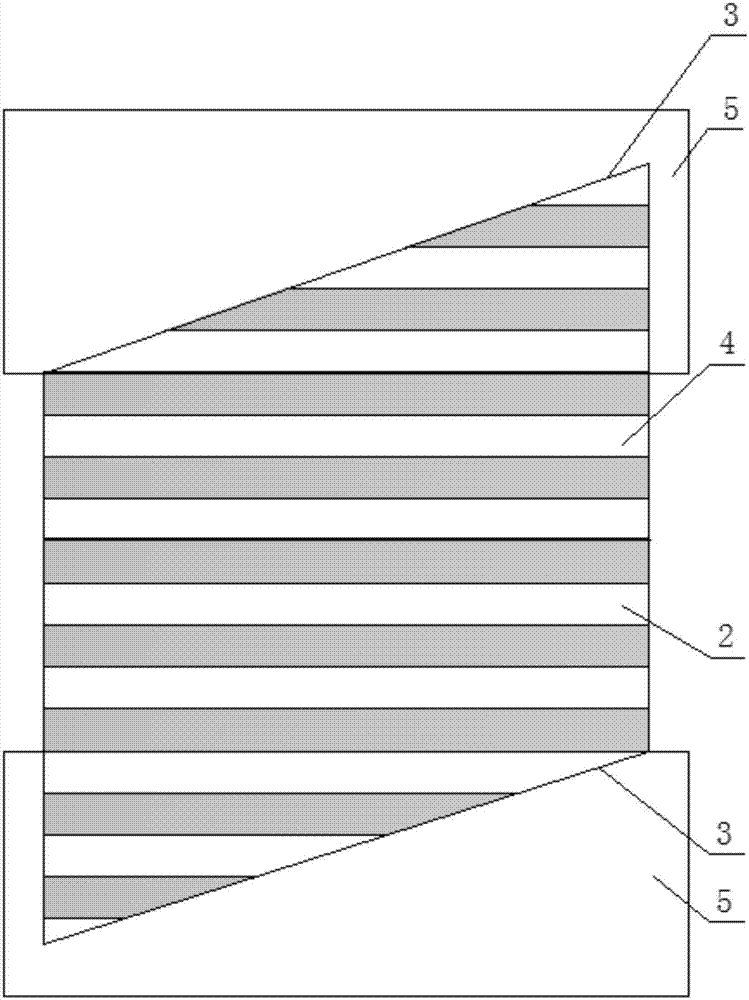

[0032] Example 1: The horizontal ultra-wide two-color and equal-width texture designed in this example is yellow-brown and reddish-brown equal-width texture, and the texture width is 55 mm. The manufacturing method of the recombined decorative veneer in this example is as follows:

[0033] 1. A round of billets: 300 yellow-brown and reddish-brown veneers each with a thickness of 1mm and 2440 mm in length, 1 mm in thickness, and 2440 mm in length, with uniform color and luster of the veneer core and wood defects removed, are used as the raw material sheet According to the method of changing the color of the sheets, the yellow-brown and red-brown raw material veneers are stacked along the grain at intervals to form a single slab.

[0034] 2. One round of gluing, pressurization, curing, and edge sawing: use moisture-curing isocyanate glue to coat the raw material veneers that make up the single slab layer by layer, and the amount of glue applied is 115g / m 2 , the position sequenc...

Embodiment 2

[0043] Embodiment 2: The horizontal ultra-wide two-color unequal width texture designed in this embodiment is dark brown and light brown unequal width texture, the width of dark brown texture is 45mm, and the width of light brown texture is 90mm, then this embodiment recombines the decorative veneer The manufacturing method is as follows:

[0044] 1. A round of blanks: the core of the veneer is uniform in color, and the wood defects are removed. The length is 2440mm, the moisture content of the veneer is 45%, the thickness of the dark brown veneer is 1mm, and the thickness of the light brown veneer is 2mm. 100 sheets are the raw material veneers. According to the method of changing the color of the sheets, the dark brown and light brown raw material veneers are stacked along the grain at intervals to form a veneer.

[0045] 2. One round of gluing, pressurizing, curing, and edge sawing: use moisture-curing isocyanate glue to coat the raw material veneers that make up the single...

Embodiment 3

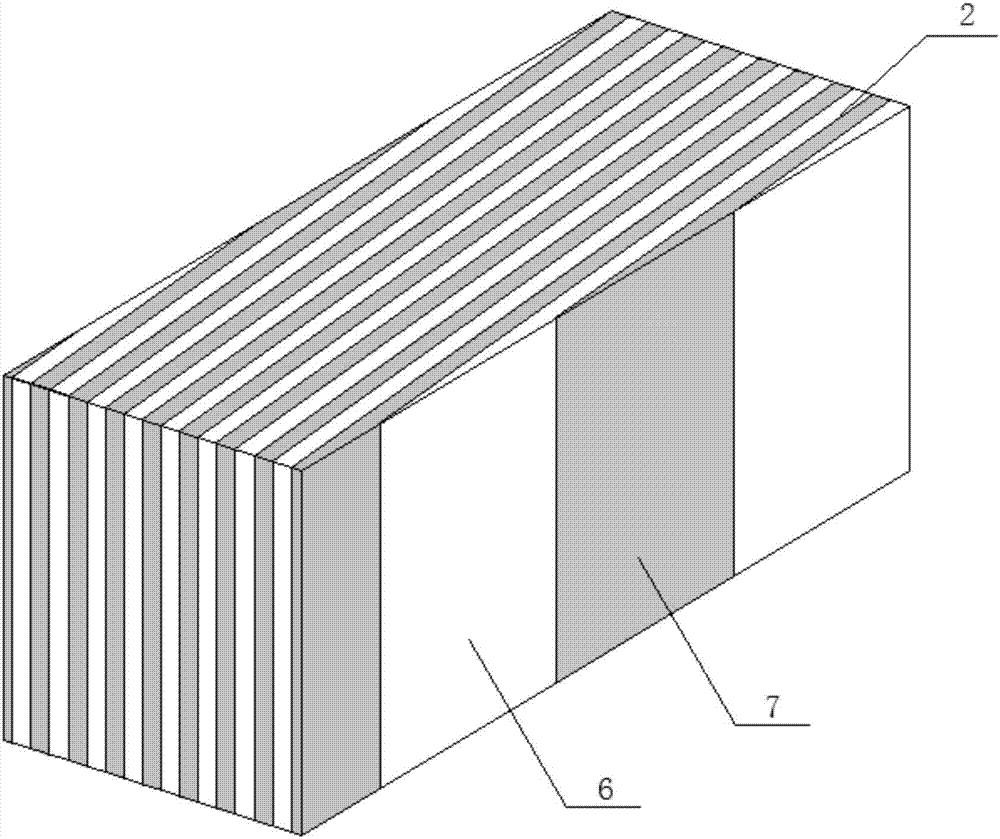

[0051] Embodiment 3: The horizontal ultra-wide three-color unequal width texture designed in this embodiment is dark brown, light brown, white unequal width texture, wherein the width of dark brown texture is 20mm, the width of light brown texture is 40mm, and the width of white texture is 30mm, the manufacturing method of the recombined decorative veneer in this embodiment is as follows:

[0052] 1. A round of billets: the core of the veneer has a uniform color, removes wood defects, has a length of 2440mm, a veneer with a moisture content of 45%, a dark brown veneer with a thickness of 1mm, a light brown veneer with a thickness of 2mm and 200 sheets of white veneers with a thickness of 1.5mm are used as raw material veneers. According to the blanking method of changing the color of the sheets, the dark brown, light brown and white raw material veneers are stacked at intervals along the grain to form a veneer.

[0053] 2. One round of gluing, pressurizing, curing, and sawing:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com