Process for manufacturing decoration thin panel

A thin panel, thin plate technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult assembly line continuous production, high manufacturing cost, insufficient smoothness, etc., achieve decorative properties and durability, smooth and beautiful, low manufacturing cost, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

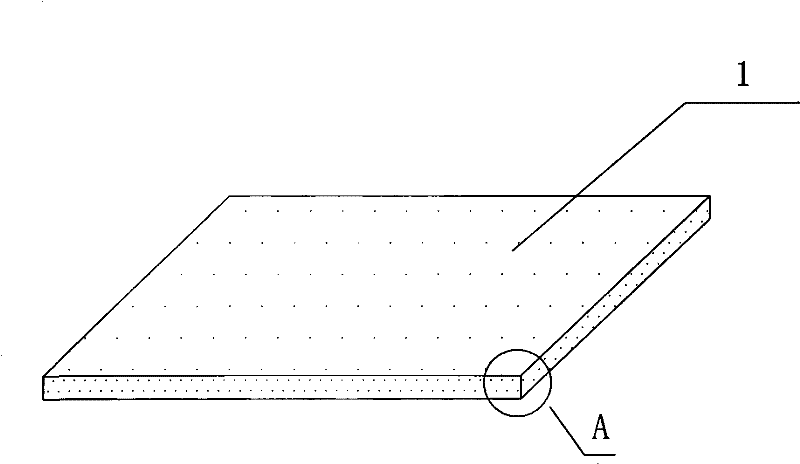

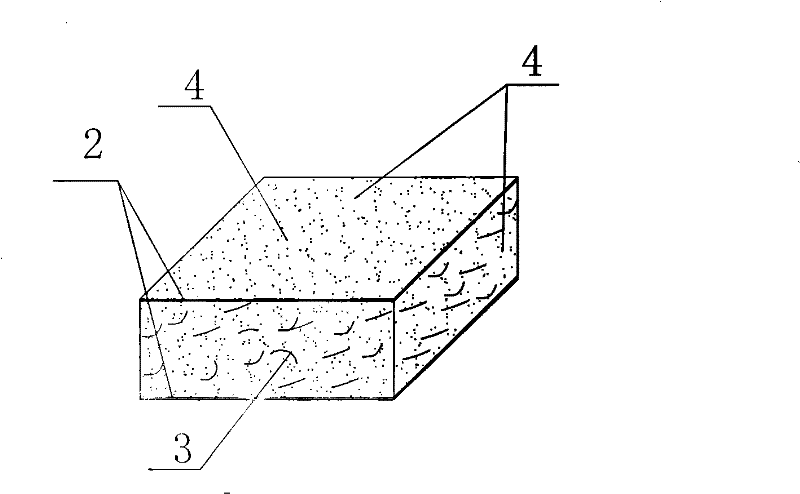

[0012] Refer to attached picture. The present invention is a pouring plate 1 with inorganic cement as the main material and a thickness of 2mm-10mm, and mixed with water-emulsion resin composite additives, short fibers 3 and closed-cell perlite powder 4. During preparation, the water-emulsion type The mass ratio of resin to inorganic cement is 1:5-15, the mass ratio of short fiber 3 to inorganic cement is 1:50-200, and the mass ratio of closed-cell perlite powder 4 to inorganic cement is 1:5-15 , an alkali-resistant glass fiber mesh cloth 2 is provided near the upper and lower surfaces of the sheet.

[0013] Among them, the water-emulsion resin refers to an emulsion with excellent chemical and electrolytic resistance, and acrylic emulsion can be used for it. It can improve the flexibility of the board of the present invention, and is beneficial to weather resistance and crack resistance. Experiments have shown that if the amount added is too much, it will be unfavorable for d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com