A kind of fireproof type superhydrophobic coating and preparation method thereof

A super-hydrophobic coating and flame-resistant technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of limited scale production of super-hydrophobic coatings, batch transportation in construction environments, hidden safety hazards of super-hydrophobic coatings, and potential safety hazards of super-hydrophobic coatings , to achieve the effects of easy storage and transportation, anti-sedimentation, and atmospheric residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method includes the following steps: adding inorganic micro-nano particles into a hydrofluoroether solvent, ultrasonically dispersing for 10-60 minutes and mechanically stirring at room temperature for 10-60 minutes, then adding alloy powder, additives and pigments according to the proportion, and continuing Stir for 30-60min, and finally add fluorosilane dropwise, and stir at room temperature for 24-72h to obtain a uniformly dispersed flame-resistant super-hydrophobic coating.

[0038] The alloy powder can also be replaced by powders with a size of about 1-20 μm such as polypropylene, polyethylene, silicone, fluororesin, etc., and the concentration is the same as that of the alloy powder.

[0039] When in use, the paint needs to be vigorously stirred for 5-10 minutes, then sprayed or brushed on the surface of the substrate, and finally placed in an oven at 100-200°C for 30-60 minutes to obtain a flame-retardant superhydrophobic coating.

Embodiment 1

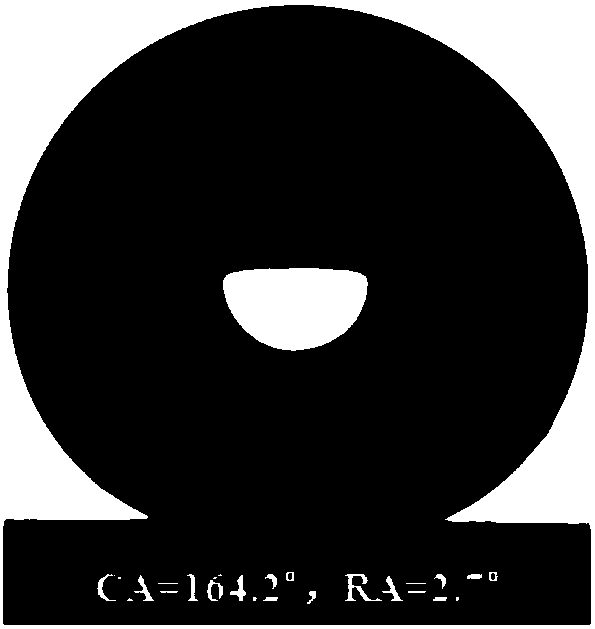

[0041] Add 0.1g of titanium dioxide nanoparticles with a particle size of 100-200nm and 0.1g of fly ash particles with a particle size of 1-20μm into 10g of nonafluorobutyl methyl ether solvent, ultrasonically disperse for 10min, then mechanically stir for 60min, then add 0.1g of particles Sn-Pb alloy with a diameter of 1-20 μm, 1 mg of mixing aid (equal parts of dispersant, anti-settling agent and rosin) and 10 mg of rust red, continue to stir for 30 minutes, and finally add 1 mg of fluorosilane to continue stirring / fluorination for 24 hours, and The coating was evenly sprayed on the glass substrate and dried in an oven at 100°C for 30 minutes to obtain a superhydrophobic coating with a water contact angle of 164.2° and a rolling angle of 2.7° ( figure 1 ).

Embodiment 2

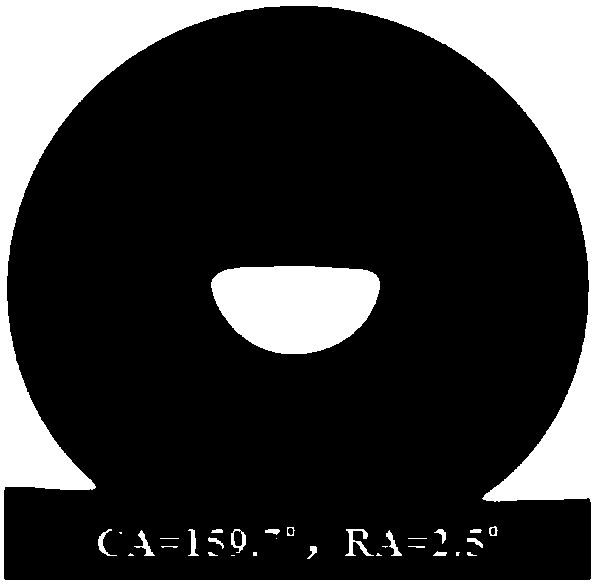

[0043]Add 0.5g of fumed silica with a particle size of 10-100nm into 50g of nonafluorobutyl methyl ether solvent, ultrasonically disperse for 30min, then mechanically stir for 30min, then add 1g of Sn-Zn alloy with a particle size of 1-20μm, 10mg of mixing aid agent and 50mg titanium dioxide, continue to stir for 60min, finally add 5mg of fluorosilane, continue mechanical stirring / fluorination for 36h, spray the obtained superhydrophobic coating on metal (copper, aluminum, stainless steel, etc.) The superhydrophobic coating was obtained by drying for 60 min in medium temperature, and its water contact angle was 159.7 °, and the rolling angle was 2.5 ° ( figure 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com