Air cylinder actuator with safety device

A safety device and actuator technology, applied in the direction of fluid pressure actuation device, shock absorber, shock absorber, etc., can solve problems such as cylinder actuator rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

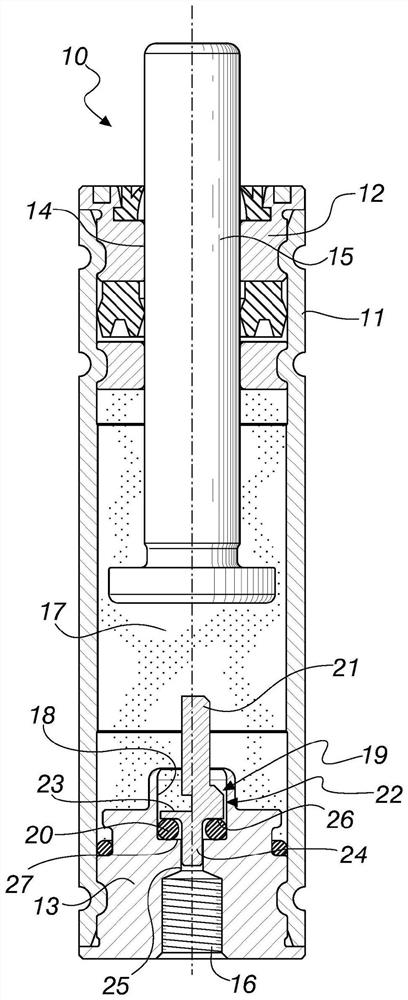

[0017] Referring to the figures, a pneumatic cylinder actuator according to the invention is indicated generally with the reference numeral 10 .

[0018] The cylinder actuator 10 includes:

[0019] - tubular housing jacket 11,

[0020] - two opposite heads 12 and 13 for closing the tubular casing 11 together with corresponding sealing elements between the heads and the casing, the first head 12 being provided with a through-hole 14 for the passage of the rod-piston 15, And the second head 13 is provided with a gas filling duct 16,

[0021] - rod-piston 15,

[0022] Between the tubular jacket 11 , the head 12 and the head 13 and the rod-piston 15 there is a chamber 17 for pressurized gas.

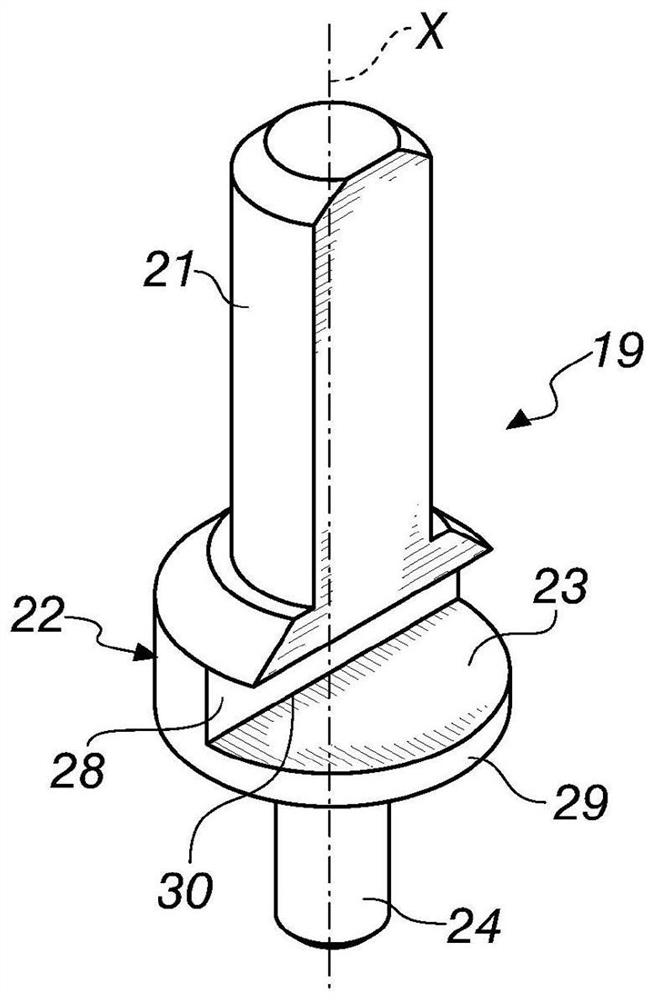

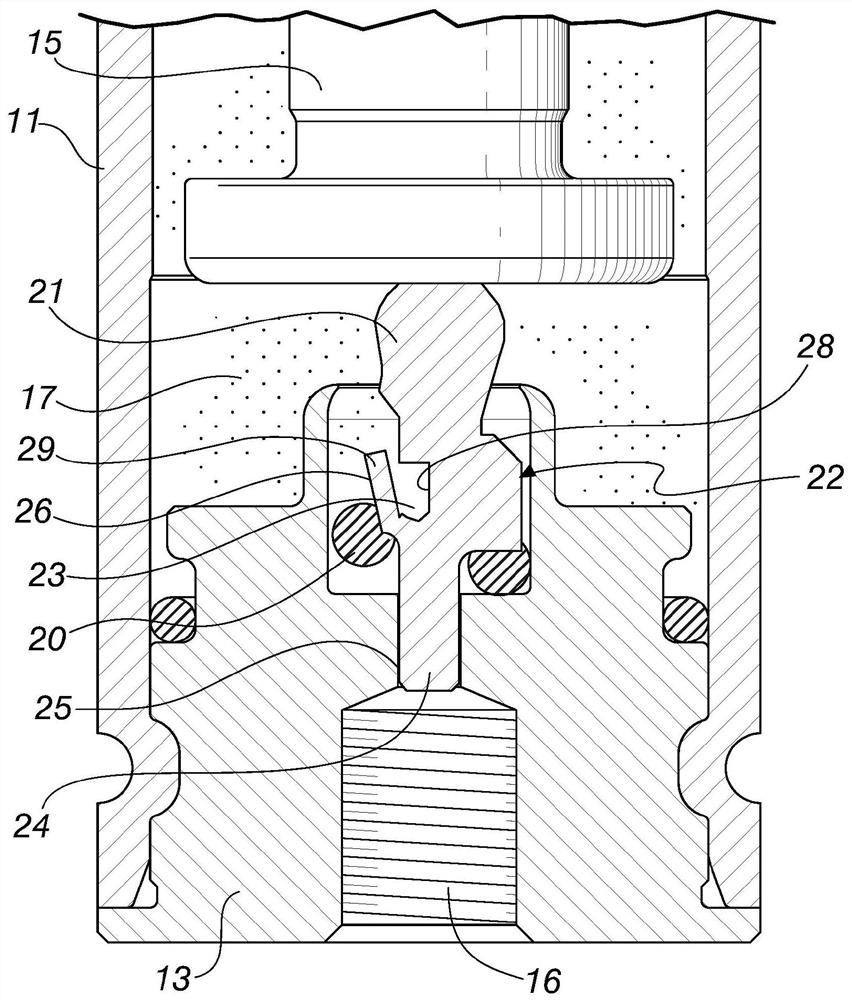

[0023] The cylinder actuator 10 is characterized in that the second head 13 has a seat 18 for accommodating the flow control element 19 of the gas-filled duct 16 and the corresponding sealing means 20 .

[0024] The flow control element 19 comprises a lug 21 for controlling the retractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com