Modified IM-5 molecular sieves, preparation method therefor, application of modified IM-5 molecular sieves and alkylation reaction method for toluene and methanol

A molecular sieve and IM-5 technology, applied in molecular sieve catalysts, chemical instruments and methods, organic chemistry, etc., can solve problems such as poor stability, low toluene conversion rate, and decreased toluene conversion rate, and achieve long service life and high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the H-IM-5 molecular sieve can be prepared according to conventional techniques, such as generally prepared according to the following steps:

[0025] The Na-type IM-5 molecular sieve (NaIM-5 molecular sieve) was subjected to ammonium exchange, then dried and calcined.

[0026] In the preparation process of the H-IM-5 molecular sieve, the ammonium exchange process may include: contacting the Na-type IM-5 molecular sieve with an ammonium nitrate solution. In the ammonium exchange process, the solid-to-liquid ratio (g / mL) of the Na-type IM-5 molecular sieve to the ammonium nitrate solution may be 1:(5-10). The concentration of the ammonium nitrate solution used may be 0.1-0.5 mol / L. Preferably, the ammonium exchange is performed multiple times, for example, 2-4 times, most preferably 3 times. Moreover, each ammonium exchange may be performed for 0.5-5 hours, preferably 1-3 hours, most preferably 2 hours.

[0027] During the preparation process...

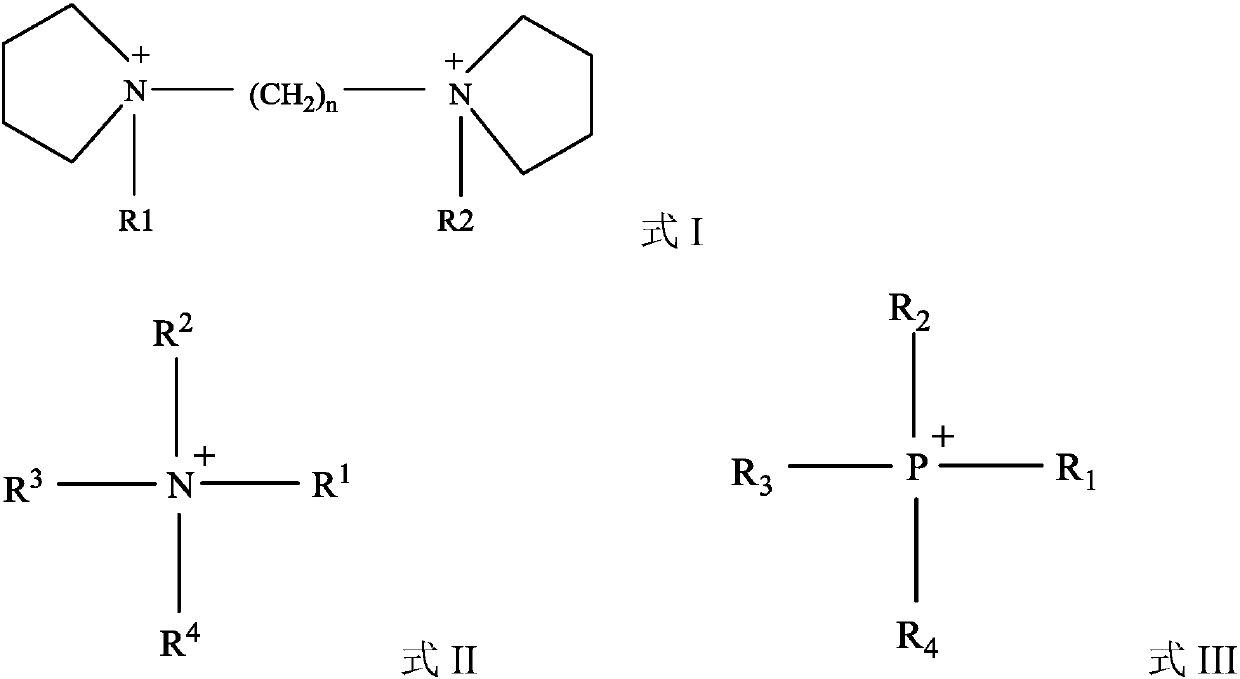

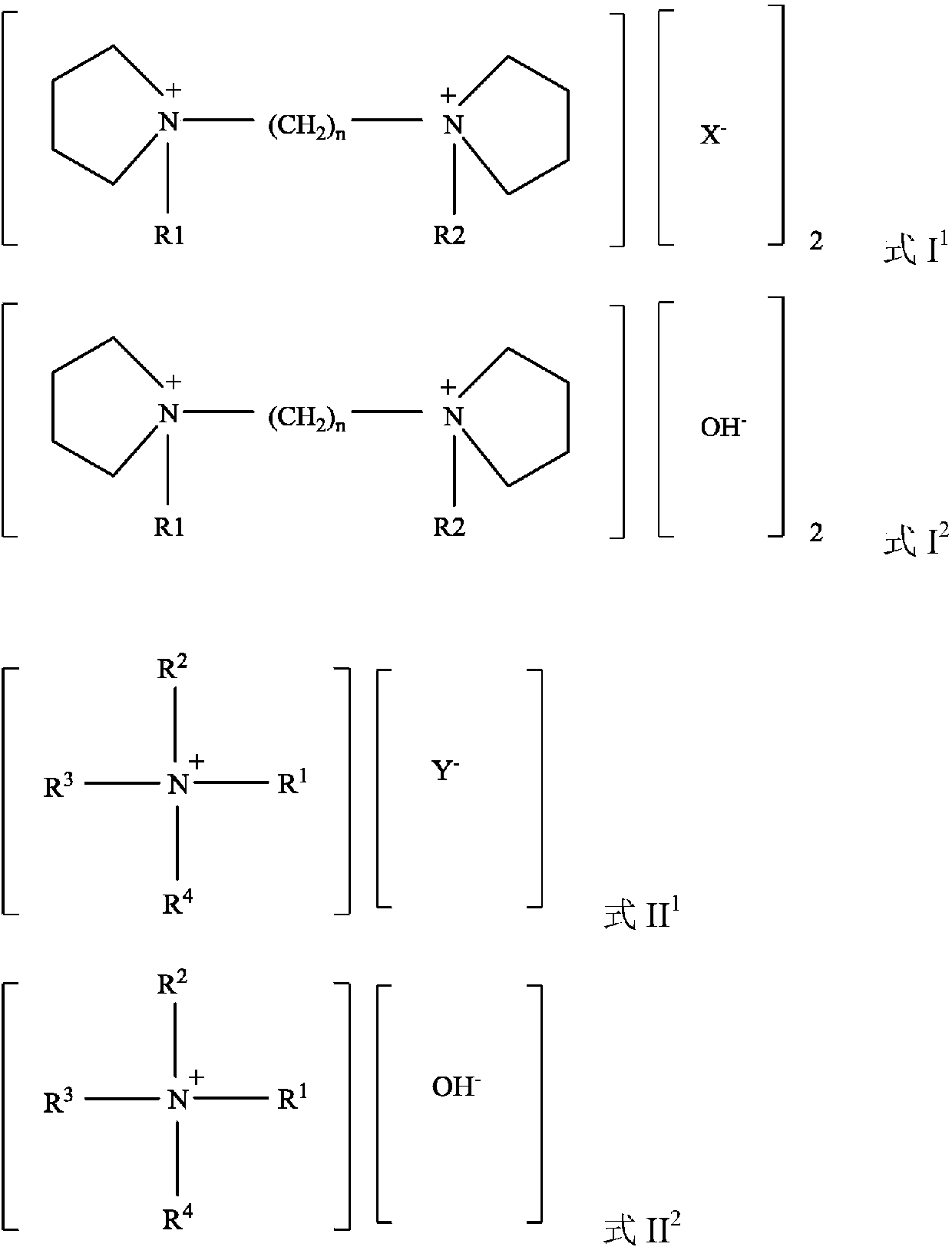

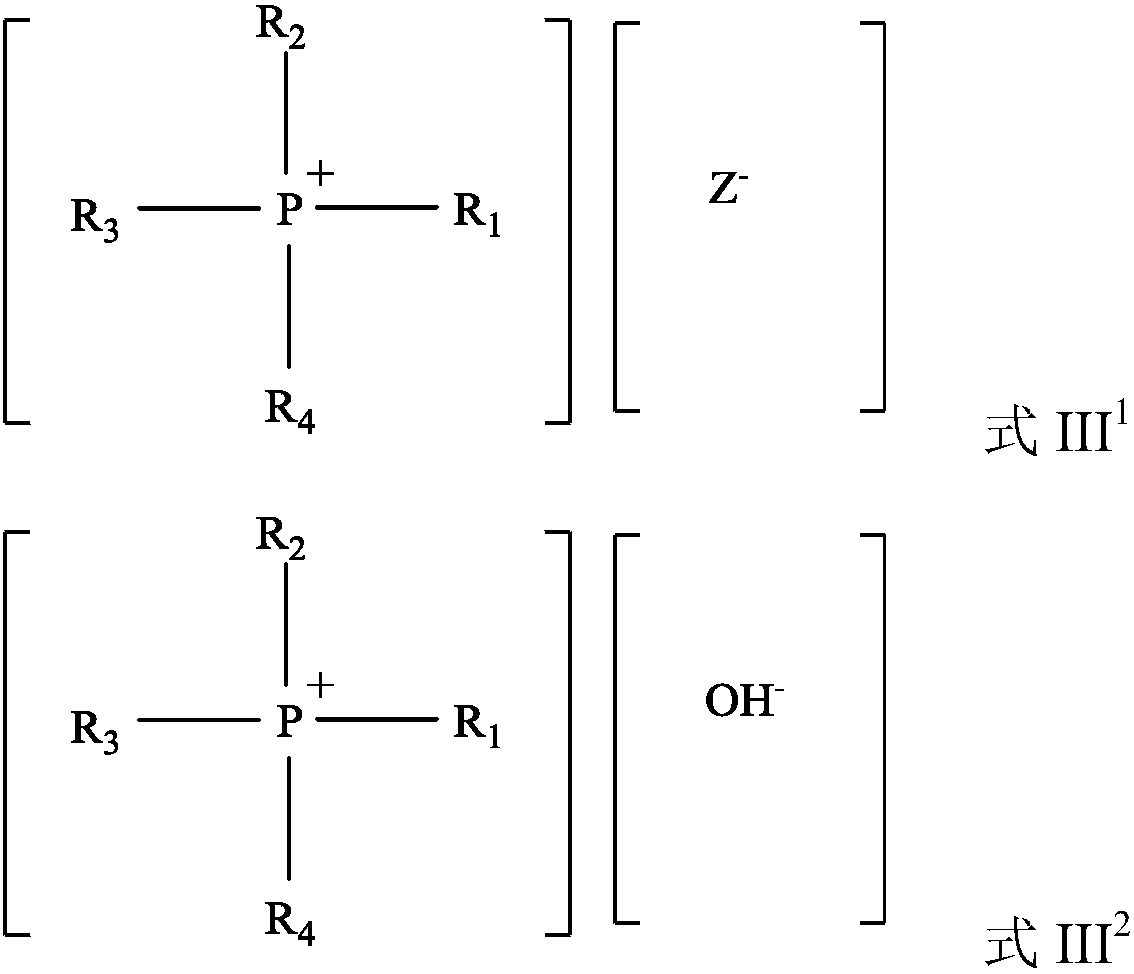

Embodiment approach

[0039] The present invention has no special limitation on the types of the quaternary ammonium cations and quaternary phosphonium cations. Described quaternary ammonium cation can be provided by quaternary ammonium salt and / or quaternary ammonium base, and quaternary ammonium salt and quaternary ammonium base can contain one quaternary ammonium cation, two quaternary ammonium cations, three quaternary ammonium cations or more, preferably contain one or Two quaternary ammonium cations; the quaternary phosphonium cations can be provided by quaternary phosphonium salts and / or quaternary phosphonium bases, which can contain one quaternary phosphonium cation, two quaternary phosphonium cations, three quaternary phosphonium cations or more Multiple, preferably containing a quaternary phosphonium cation. The quaternary ammonium salts, quaternary ammonium bases, quaternary phosphonium salts, quaternary phosphonium bases preferably each contain 8-18 carbon atoms. The quaternary ammoni...

preparation example 1

[0092] SiO 2 / Al 2 o 3 The NaIM-5 molecular sieve with a molar ratio of 38 was ion-exchanged three times with ammonium nitrate solution with a concentration of 0.5mol / L at 80°C, the solid-liquid ratio (g / mL) was 1:8, and the time for each ion exchange was 2 hours. The molecular sieve obtained after the exchange was washed with deionized water, dried at 90°C for 10 hours, and calcined at 550°C for 5 hours to obtain H-IM-5 molecular sieve P-Z 1 (Na 2 O content is less than 0.1% by mass), and the physical and chemical parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com