Automatic adjustment device for roll gap of roll crusher, and working method

A roll crusher and automatic adjustment technology, which is applied in chemical instruments and methods, solid separation, filtration and screening, etc., can solve the problems of reducing production efficiency, increasing labor intensity, time-consuming and labor-intensive, etc., and achieve high adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below.

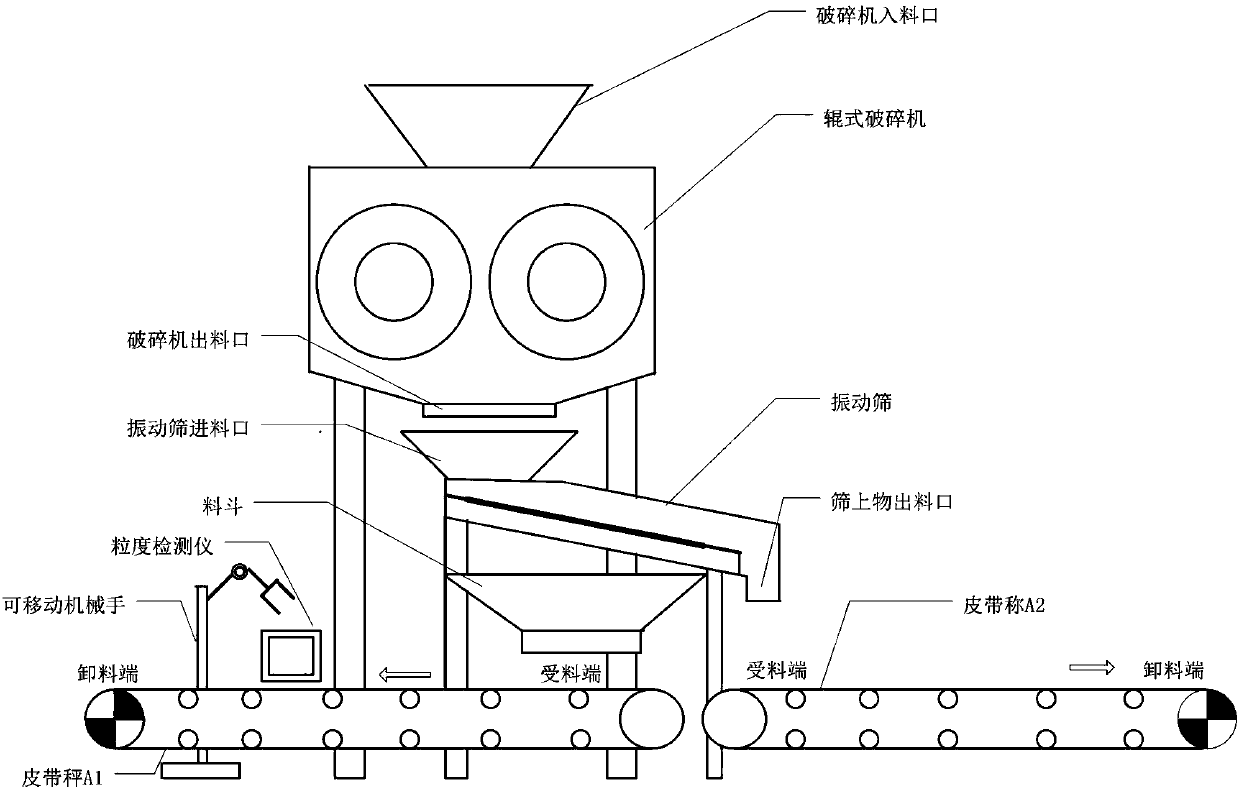

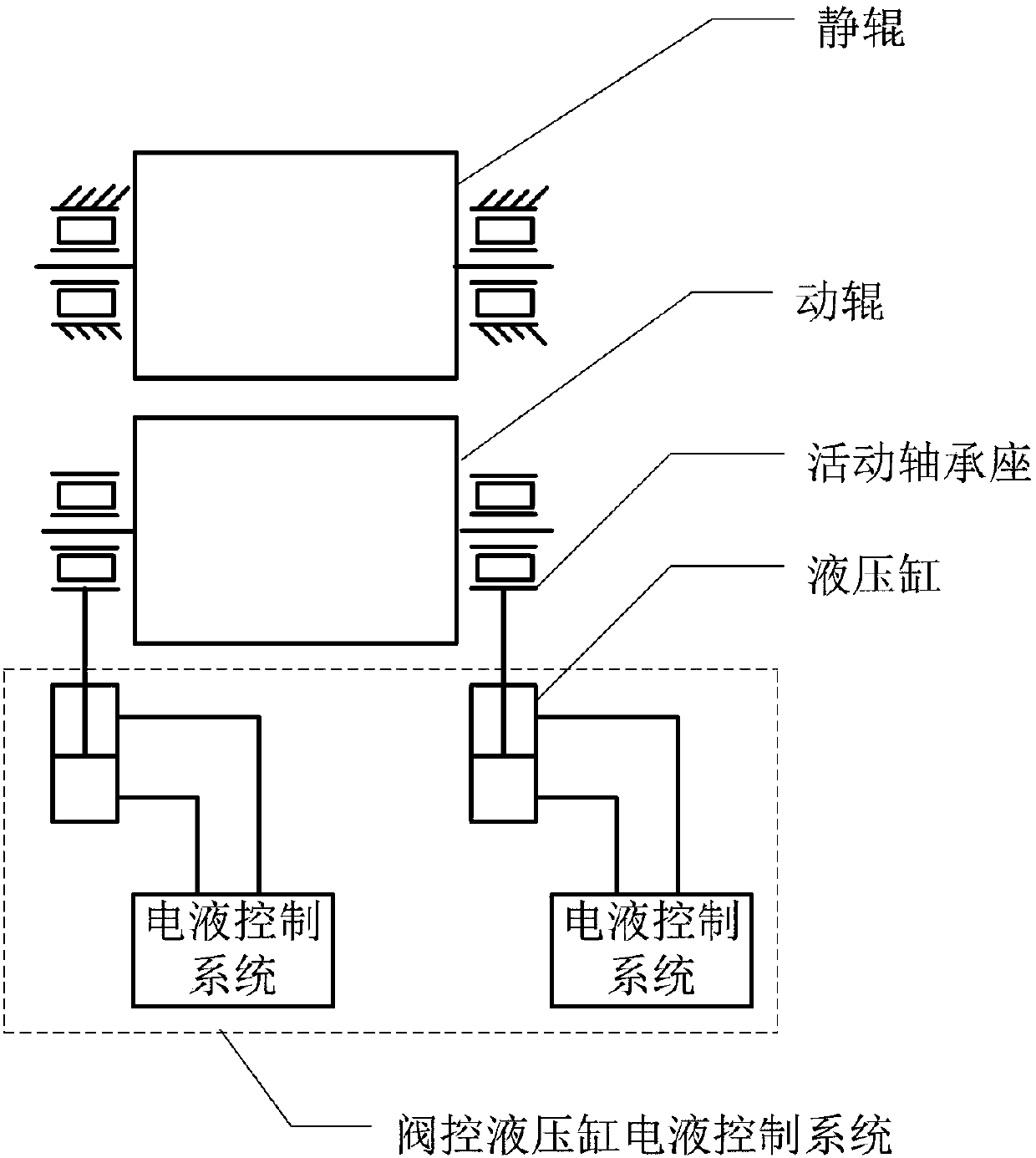

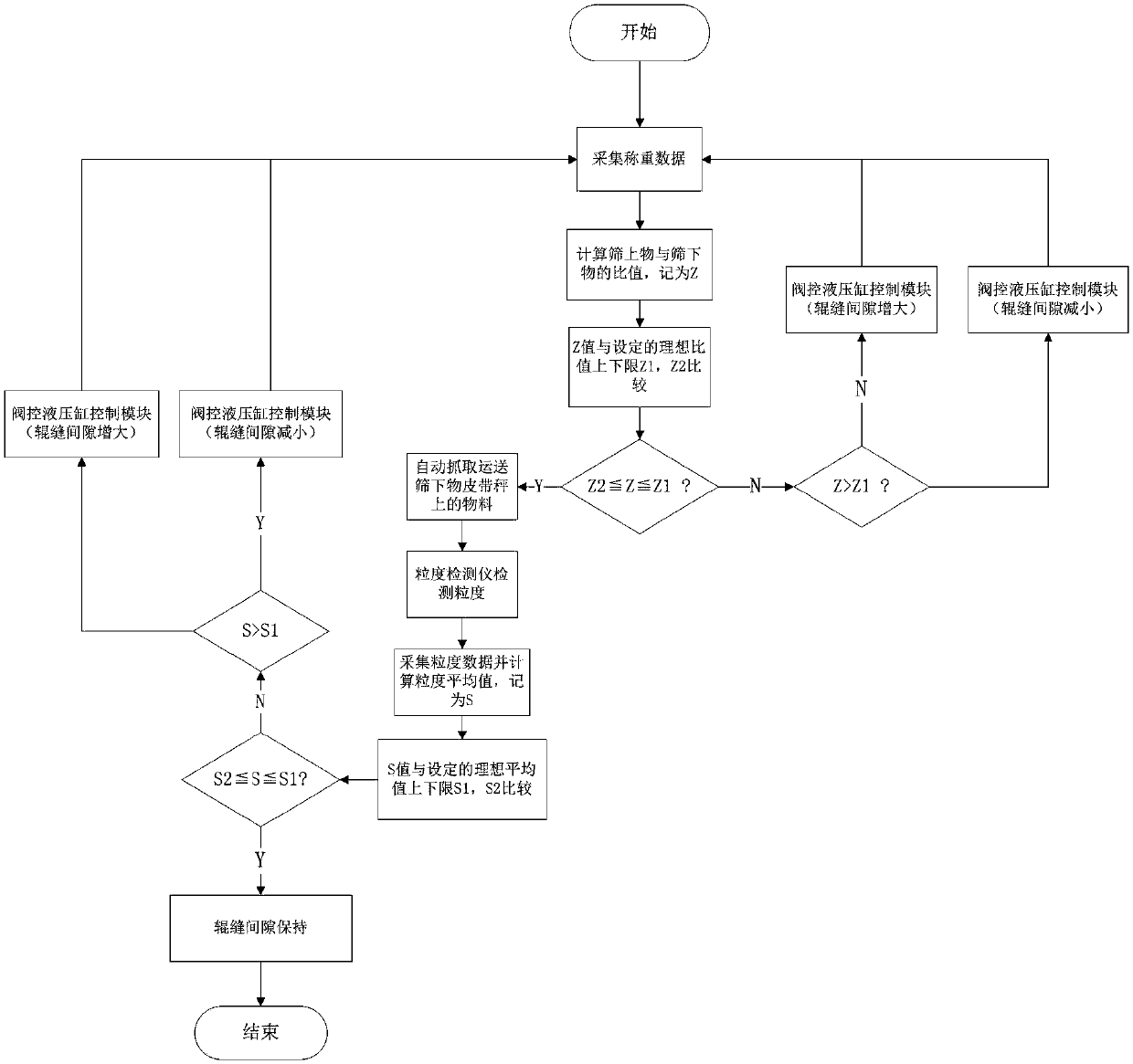

[0020] An automatic adjustment device for the roll gap of a roll crusher, comprising a vibrating screen, a belt scale A1, a belt scale A2, a movable manipulator, a particle size detector, a computer control system and an electro-hydraulic control system of a valve-controlled hydraulic cylinder. Such as figure 1 As shown, the feed port of the vibrating screen is set directly below the discharge port of the crusher, and a hopper is provided below the screen surface; the receiving end of the belt scale A1 is directly below the hopper, and the discharge end of the belt scale A1 To the finished material transportation system; the receiving end of the belt scale A2 is below the discharge port of the vibrating screen, and the discharge end of the belt scale A2 is to the feed conveying system of the crusher; the movable manipulator is arranged at The side of the belt scale A1 is used to grab the materials on the belt sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com