A large overcurrent strong shear mixing chopper for sewage treatment

A technology of sewage treatment and strong shearing, applied in the field of fluid machinery, can solve the problems of increasing the motor load of pump conveying equipment, poor passability, instability of the start-stop rotor, etc., to ensure the impeller passing rate, obvious effect, and strong flow capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

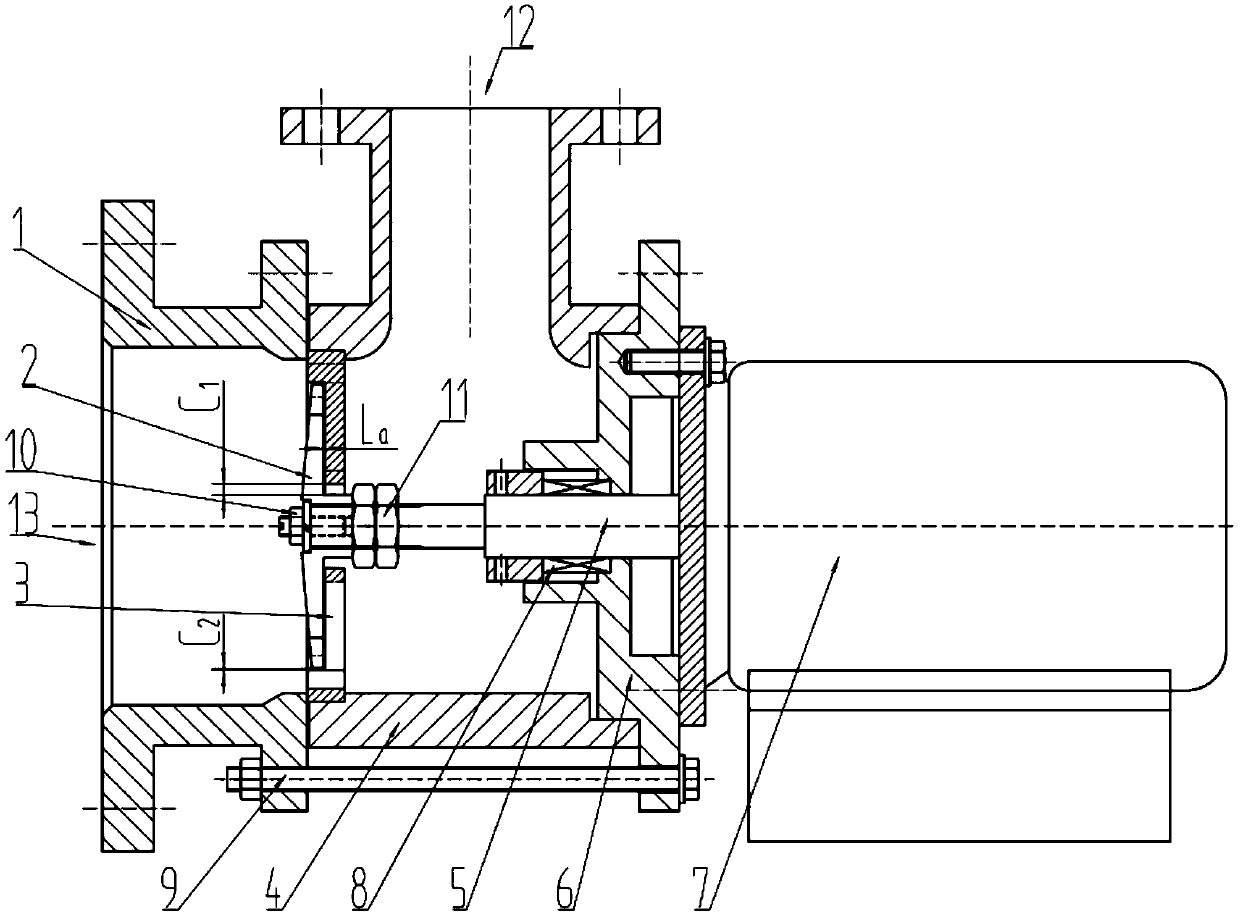

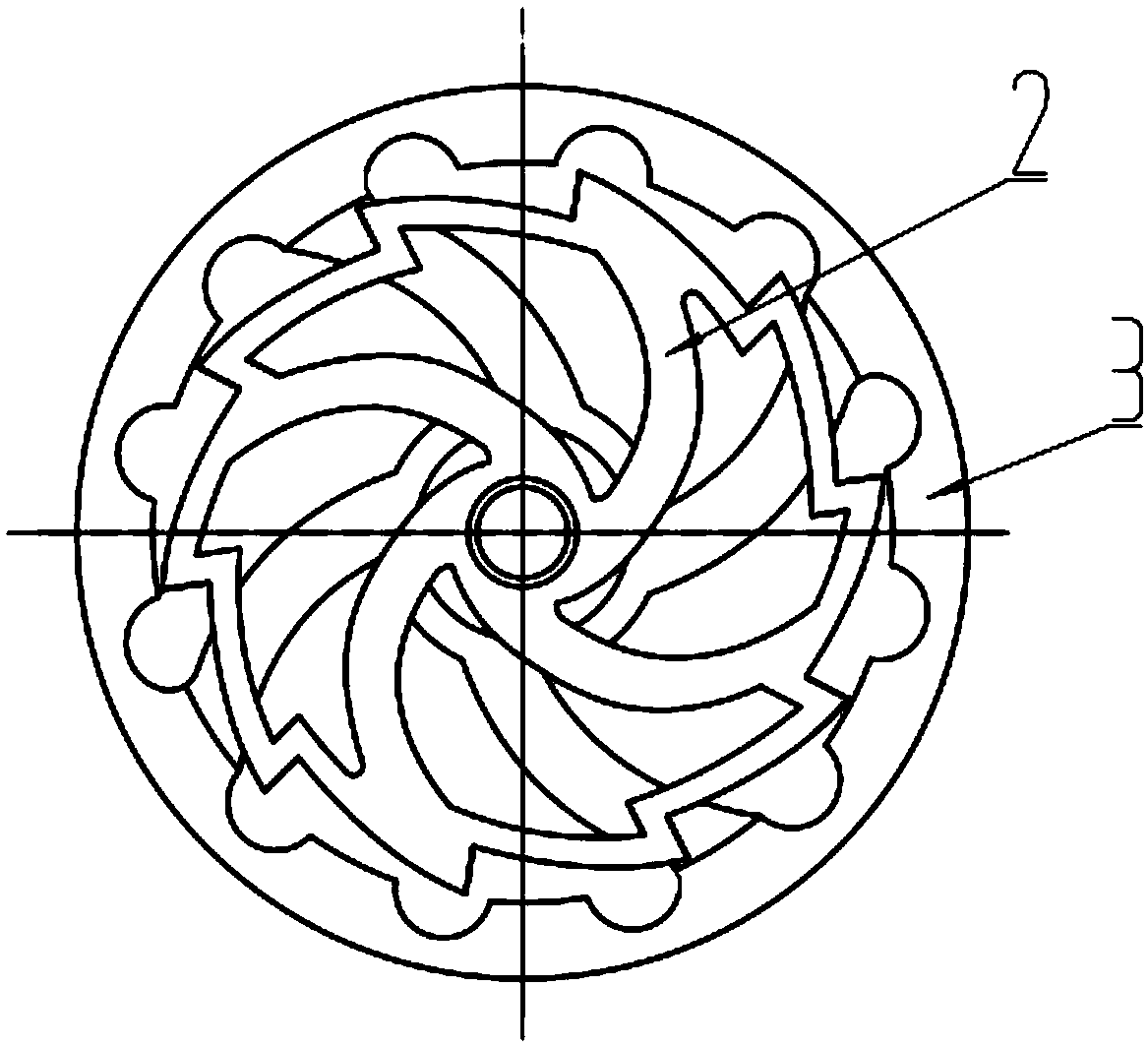

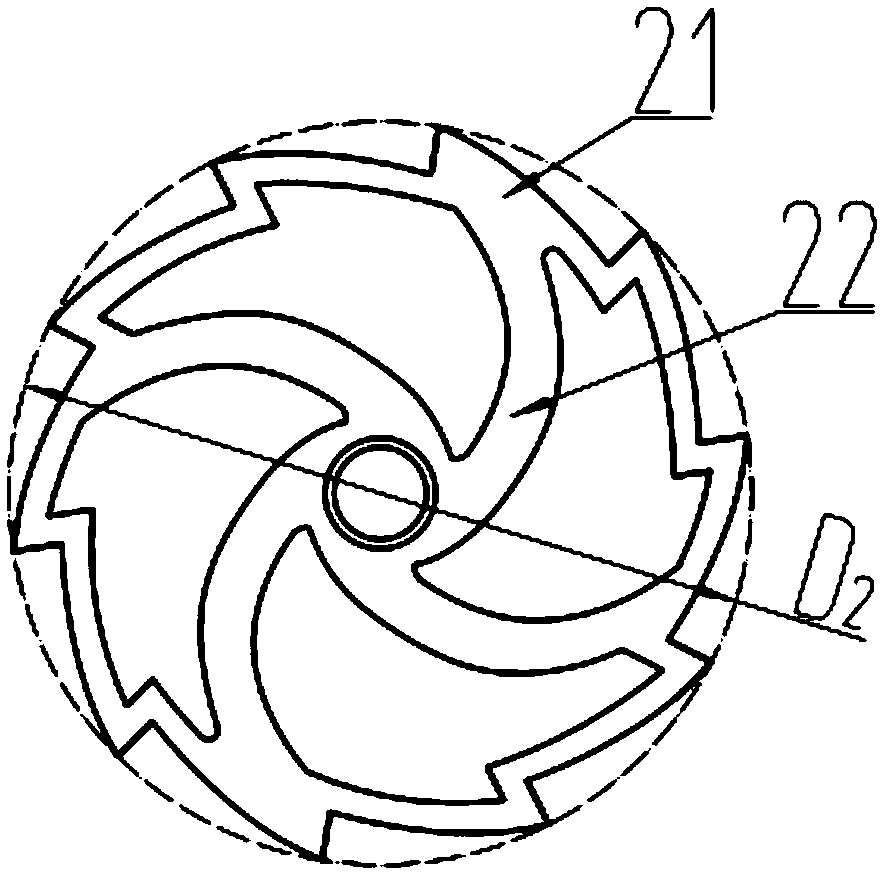

[0033] figure 1 Shown is an embodiment of the large overcurrent strong shear mixing chopper for sewage treatment in the present invention, the large overcurrent strong shear agitation chopper for sewage treatment includes a front chamber 1 , moving cutting disc 2, static cutting disc 3, mixing cavity 4, main shaft 5, back cover 6 and power source 7. The front chamber 1 , the mixing chamber 4 and the rear cover 6 are installed sequentially and tightened by the lead screw 9 . The front end of the front chamber 1 is provided with an inlet 13, the rear end communicates with the front end of the mixing chamber 4, the rear end of the mixing chamber 4 is connected with the rear cover 6, and the middle part of the mixing chamber 4 is provided with an outlet 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com