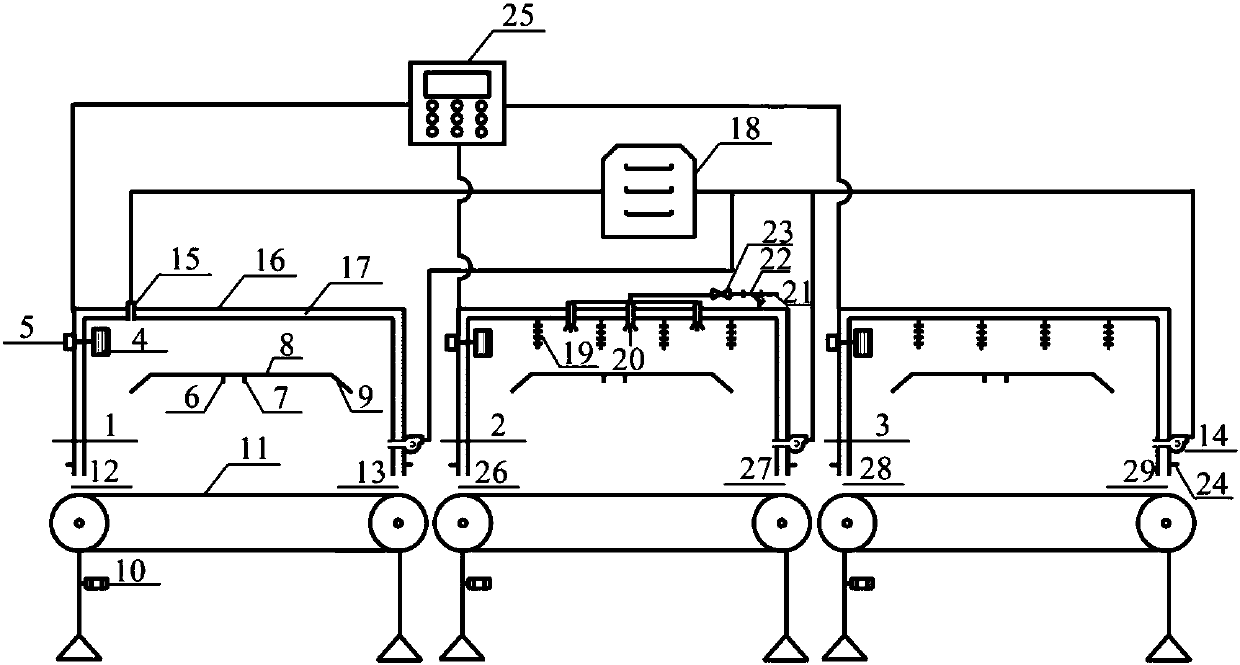

Water-borne wood ware paint drying equipment and method

A technology of water-based wood paint and drying equipment, which is applied in the direction of pretreatment surface, coating, and surface coating liquid device, etc., which can solve the unfavorable automation of kiln drying equipment, assembly line production operation, large heat loss, and difficult dynamic adjustment Problems such as temperature and humidity, to achieve the effect of small energy dissipation, low drying energy consumption and production cost, and convenient automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for drying an aqueous polyurethane primer, comprising the following steps:

[0045] (1) Temperature and humidity adjustment in the drying section: the drying section starts to heat up first, the circulation fan is turned on, the wind speed is 1.5m / s, and the temperature of the cavity is controlled at 50°C. When the temperature is 10% lower than the set value, the U-finned stainless steel heating tube starts to heat; when the temperature exceeds 10% of the set value, the U-shaped finned stainless steel heating tube stops heating, the dehumidification fan is turned on, and the hot air passes through After the outlet of the dehumidification fan enters the heat pump dehumidification dryer with the waste heat returning component, it enters the preheating section through the air inlet 15. After starting to heat up in the cavity of the drying section, the relative humidity of the cavity of the drying section is controlled at 45%. When the relative humidity is 20% low...

Embodiment 2

[0050] A method for drying one-component water-based polyurethane paint, comprising the following steps:

[0051] (1) Temperature and humidity adjustment in the drying section: the drying section starts to heat up first, the circulation fan is turned on, the wind speed is 1m / s, and the temperature of the cavity is controlled at 45°C. When the temperature is 15% lower than the set value, the U-finned stainless steel heating tube starts to heat; when the temperature exceeds 15% of the set value, the U-shaped finned stainless steel heating tube stops heating, the dehumidification fan is turned on, and the hot air passes through After the outlet of the dehumidification fan enters the heat pump dehumidification dryer with the waste heat returning component, it enters the preheating section through the air inlet 15. After starting to heat up in the cavity of the drying section, the relative humidity of the cavity of the drying section is controlled at 55%. When the relative humidit...

Embodiment 3

[0056] A method for drying two-component waterborne polyurethane paint, comprising the following steps:

[0057] (1) Temperature and humidity adjustment in the drying section: the drying section starts to heat up first, the circulation fan is turned on, the wind speed is 0.5m / s, and the temperature of the cavity is controlled at 35°C. When the temperature is 15% lower than the set value, the U-finned stainless steel heating tube starts to heat; when the temperature exceeds 15% of the set value, the U-shaped finned stainless steel heating tube stops heating, the dehumidification fan is turned on, and the hot air passes through After the outlet of the dehumidification fan enters the heat pump dehumidification dryer with the waste heat returning component, it enters the preheating section through the air inlet 15. After starting to heat up in the cavity of the drying section, the relative humidity of the cavity of the drying section is controlled at 65%. When the relative humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com