A large-scale vibrating screen motion adjustment method and system

An adjustment method and adjustment system technology, which is applied to chemical instruments and methods, filter screens, solid separation, etc., can solve the problems of small range, low efficiency, and low adjustment accuracy, and achieve simple operation, good economic effect, and improved coal preparation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

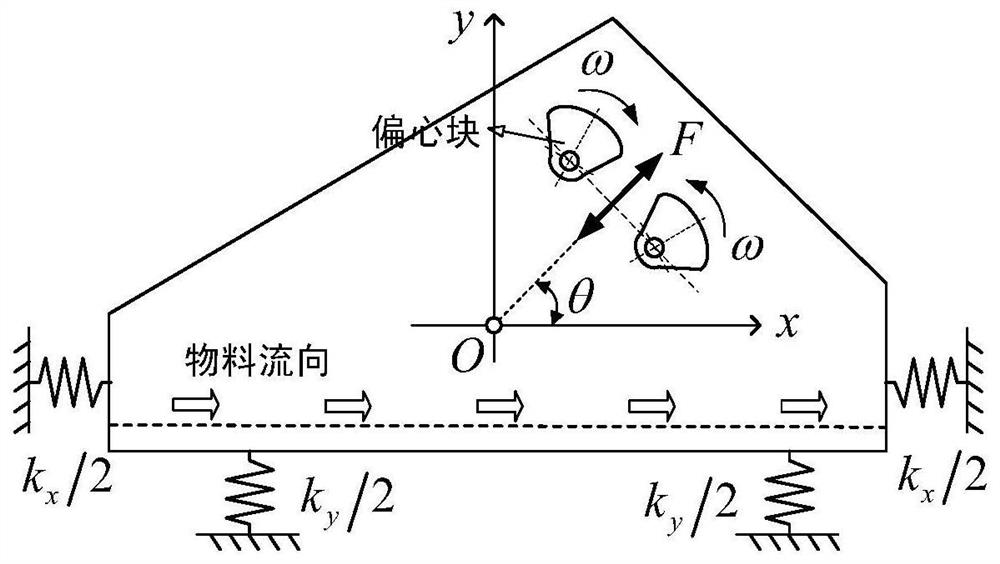

[0035] figure 1 It is the traditional vibrating screen that mostly uses the uncoupled plane two-degree-of-freedom dynamic model. The existing technology is mainly to change the amplitude of the exciting force by manually increasing or decreasing the plug on the eccentric block of the box-type vibrator or changing the eccentric position of the additional mass block. This technology can only be implemented in the shutdown state, and the adjustment accuracy Low and limited range, which is not conducive to the improvement of coal preparation production efficiency.

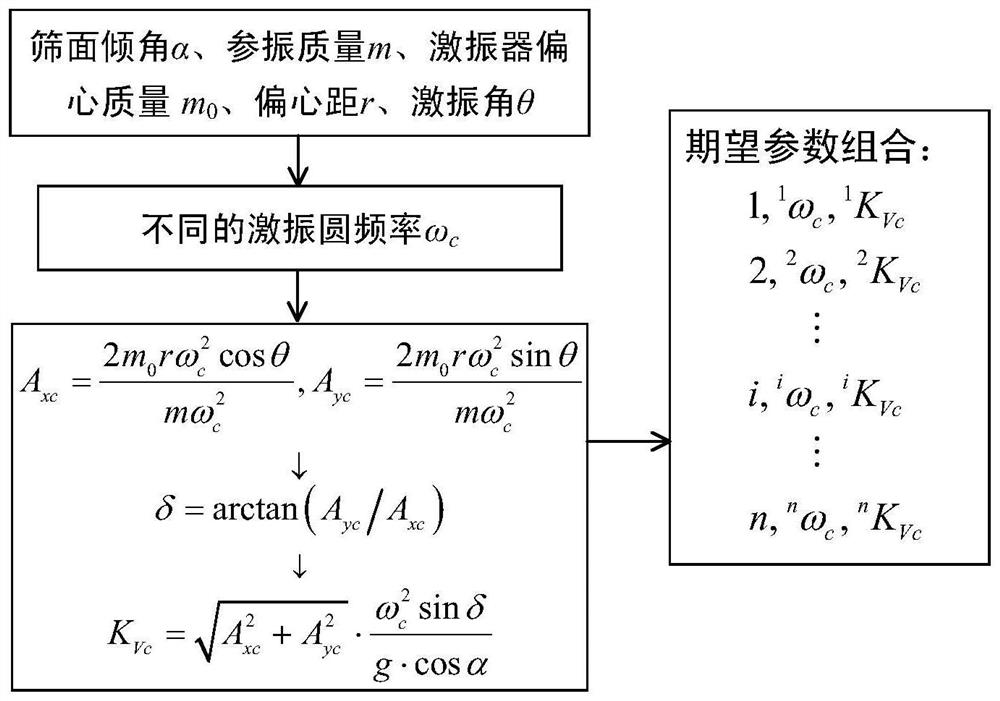

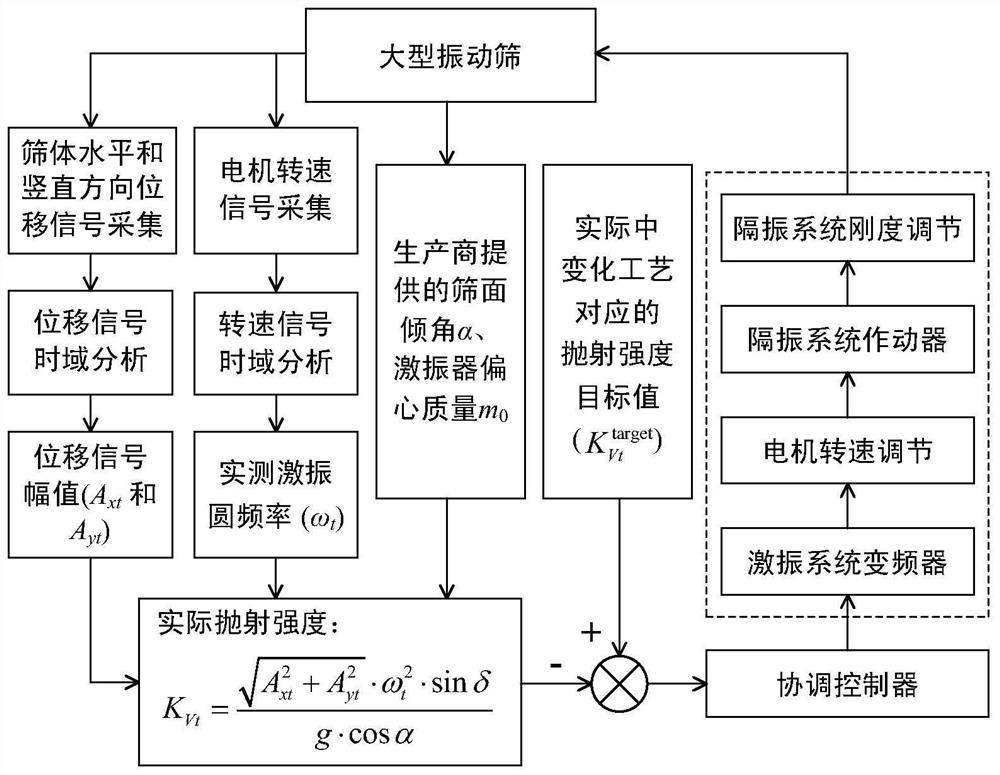

[0036] The invention provides a method for adjusting the motion of a large-scale vibrating screen. A parameter combination sample for calculating projectile intensity-exciting circle frequency is constructed through theoretical calculation. According to the required projectile intensity, the frequency of the exciting circle corresponding to the projectile intensity is first found in the sample. , and then adjust the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com