Rib inserting device angle steering device of net rack welding machine

A technology of corner device and tendon inserter, which is applied in the direction of online netting, other household appliances, household appliances, etc., to achieve the effects of improving product quality and production efficiency, high degree of automation, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments.

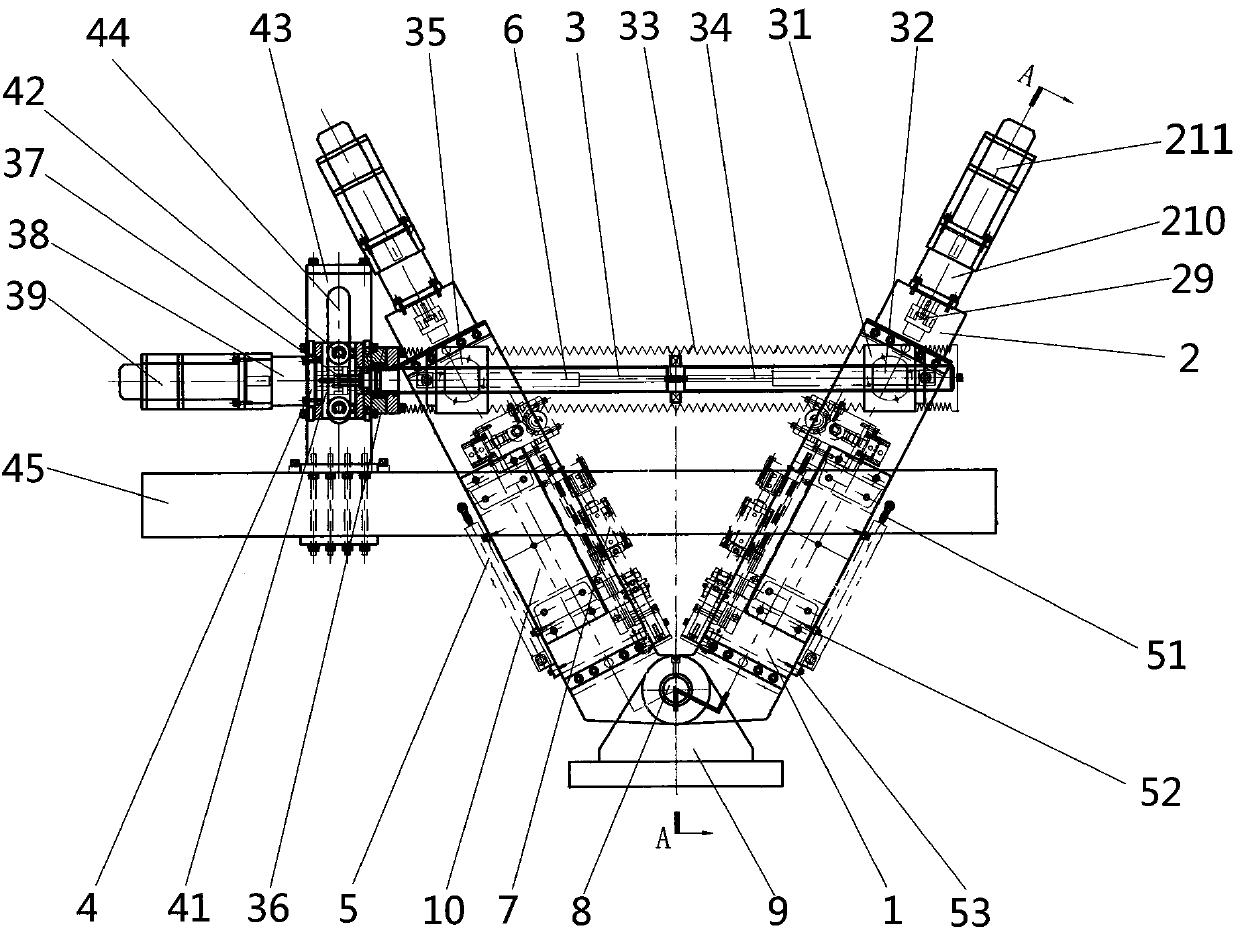

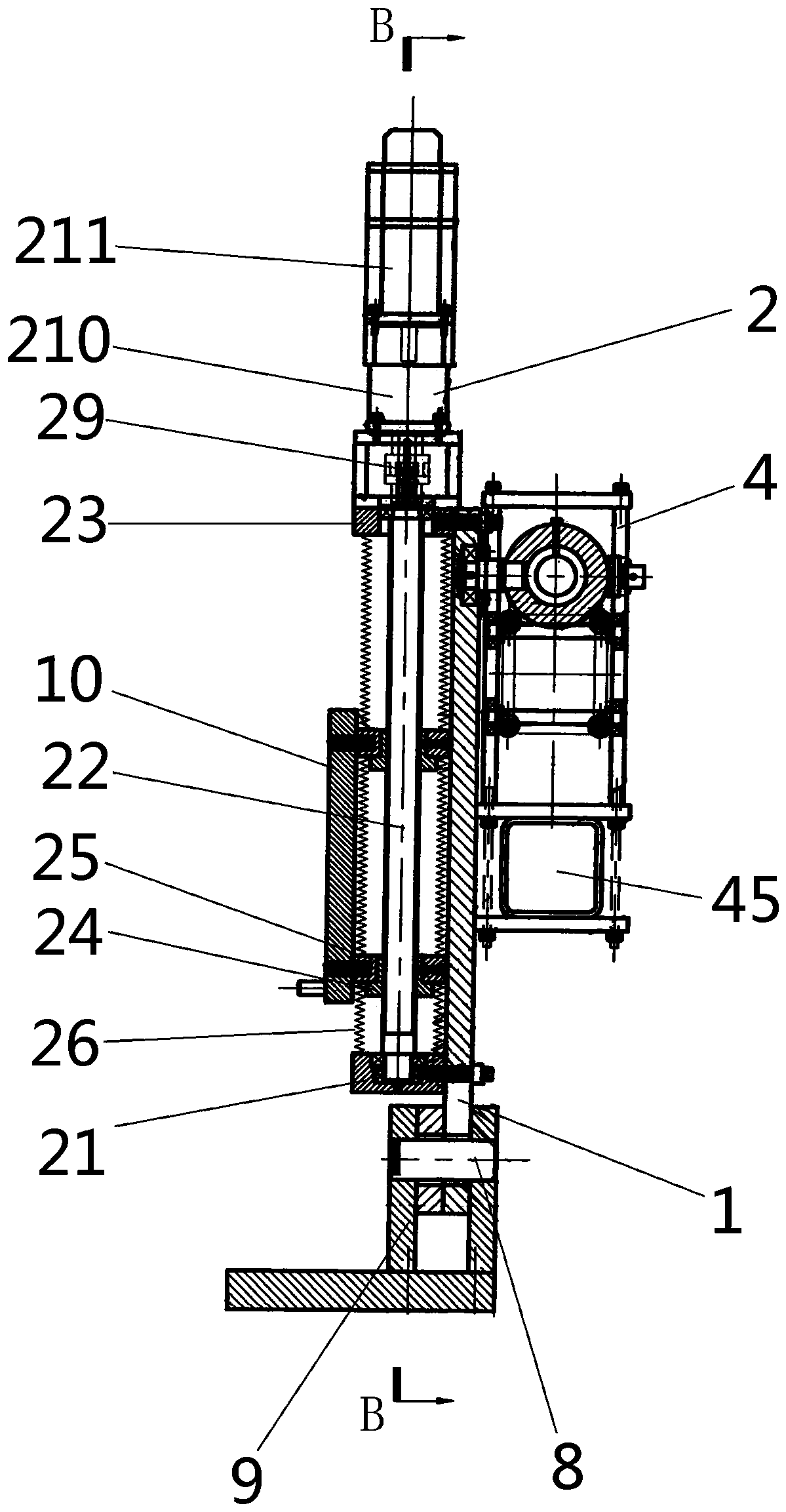

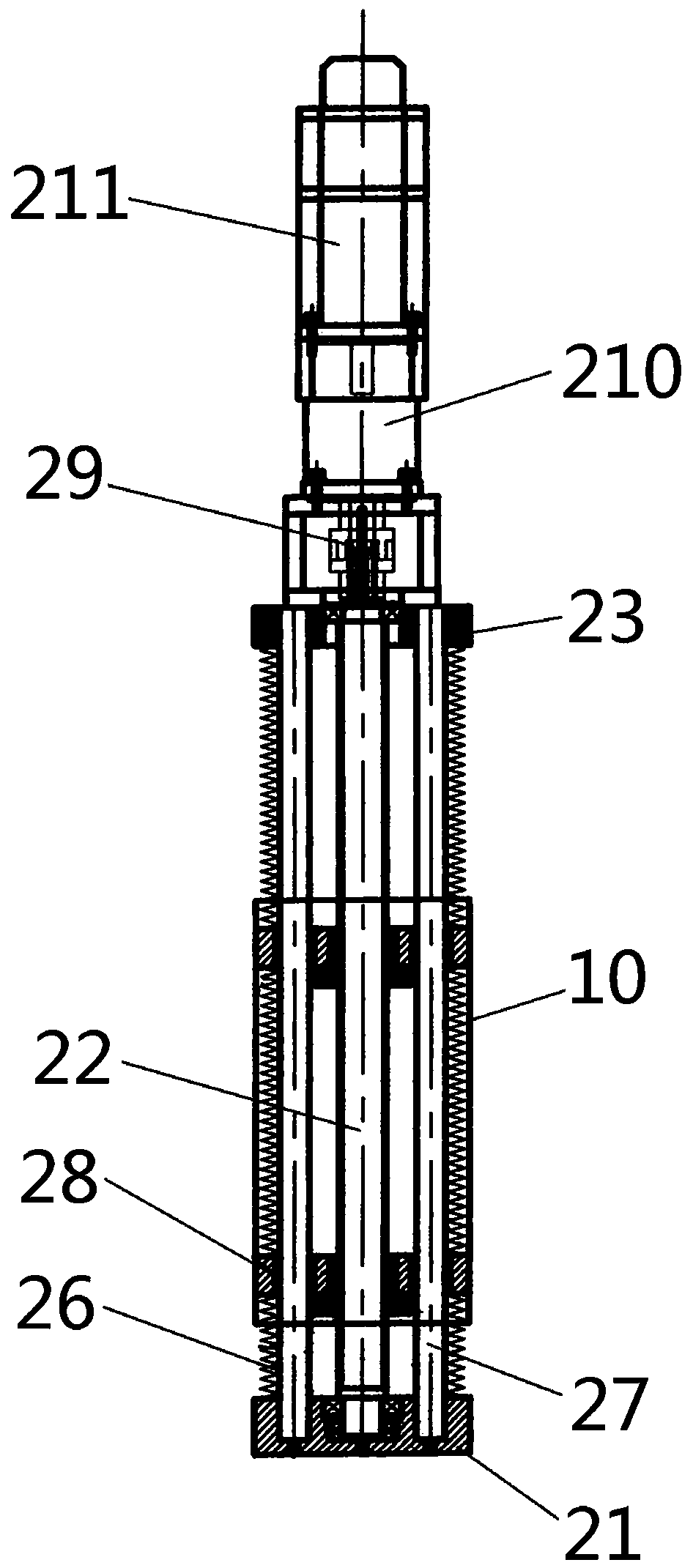

[0024] The rib inserting corner device of the grid welding machine, combined with Figure 1 to Figure 4 As shown, it includes an outer swing arm 1, a lifting mechanism 2, an angle adjustment mechanism 3, an inner swing arm 10 and a PLC controller. The two outer swing arms 1 are inclined at a certain angle, and their bottom ends are arranged on the base 9 through the base pin shaft 8, and can rotate around the base pin shaft 8; the lifting mechanism 2 is arranged on the outer swing arm 1 for driving the plug The tendon 7 is raised and lowered to be suitable for different thickness insulation boards; the angle adjustment mechanism 3 is arranged between the two lifting mechanisms 2, and is fixedly connected with the outer swing arm 1, and is used to control the angle between the two outer swing arms 1; the inner swing The arm 10 is fixedly connected to the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com