Manufacture method of anti-collision pier

A technology of anti-collision pier and concrete, which is applied in the direction of manufacturing tools, ceramic molding machines, construction, etc., can solve the problems that the surface of anti-collision pier is easy to peel off and damage, frequent repairs, etc., so as to reduce the time of form removal, reduce the amount of use, stick knot good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

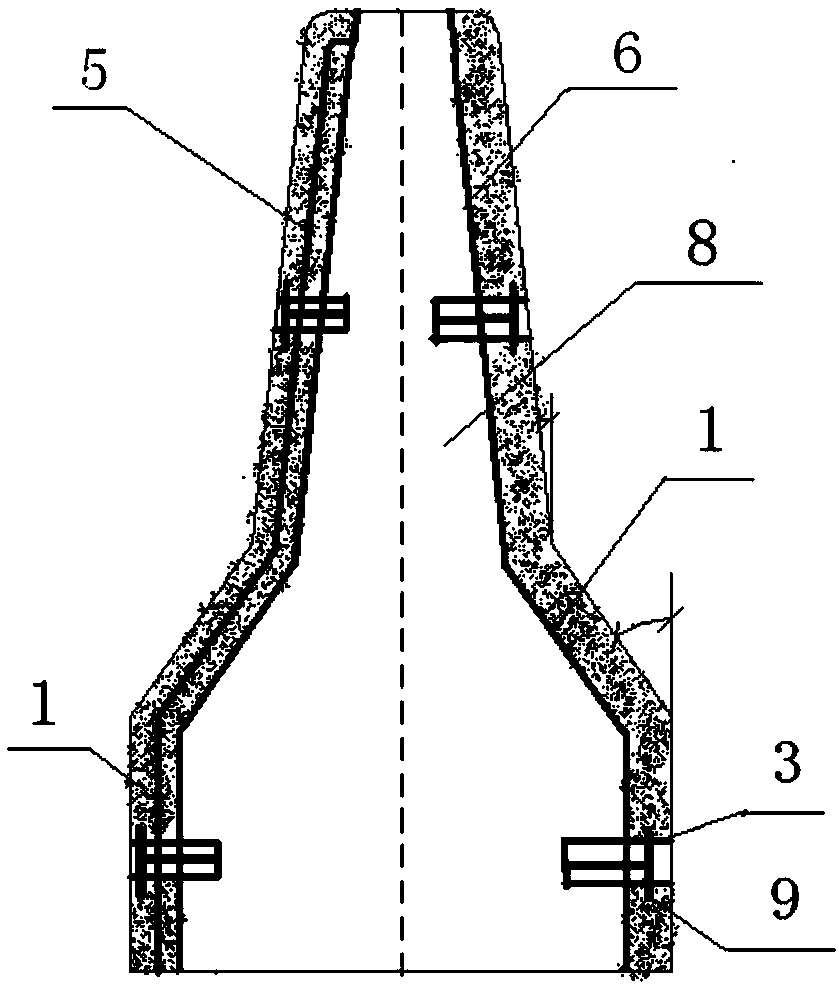

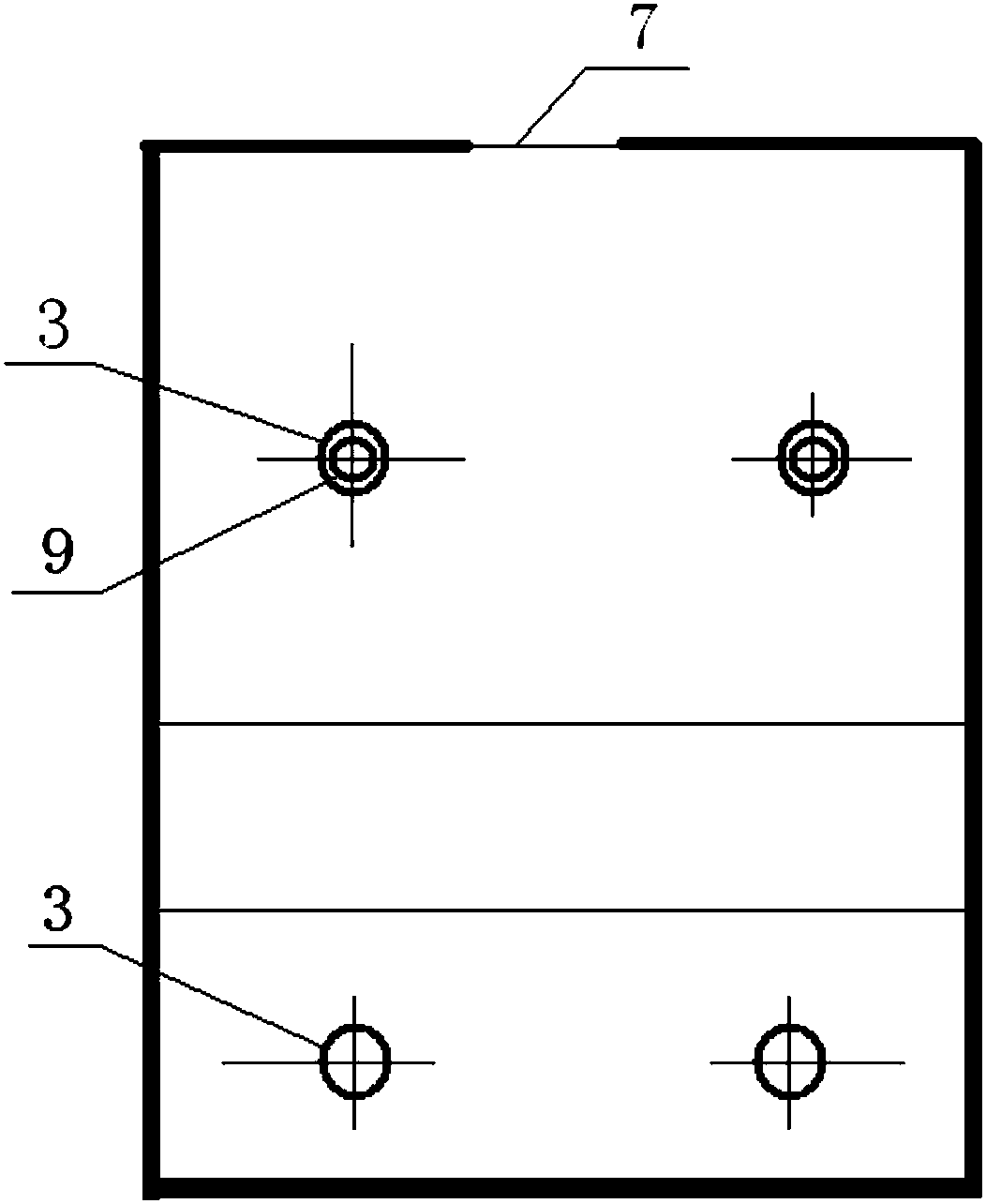

[0078] This embodiment provides an anti-collision pier, including an anti-collision pier core and an anti-collision pier shield; The side is fixed on the core of the anti-collision pier; wherein, the anti-collision pier shield is made of active powder concrete; of course, in this embodiment, the anti-collision pier shield can also be one piece, when the anti-collision pier When the bumper shield is one piece, it is fixed on the bumper core from one side, such as the left side, of the bumper core.

[0079] In this embodiment, optionally, a reinforced anti-crack net is arranged inside the anti-collision pier guard plate, and the reinforced anti-crack net is arranged along the length direction of the anti-collision pier guard plate; The mesh improves the strength of the anti-collision pier shield; and preferably, the reinforced anti-crack mesh is glass fiber mesh cloth, carbon fiber mesh cloth or steel wire mesh.

[0080] In this embodiment, the anti-collision pier protective pl...

Embodiment 2

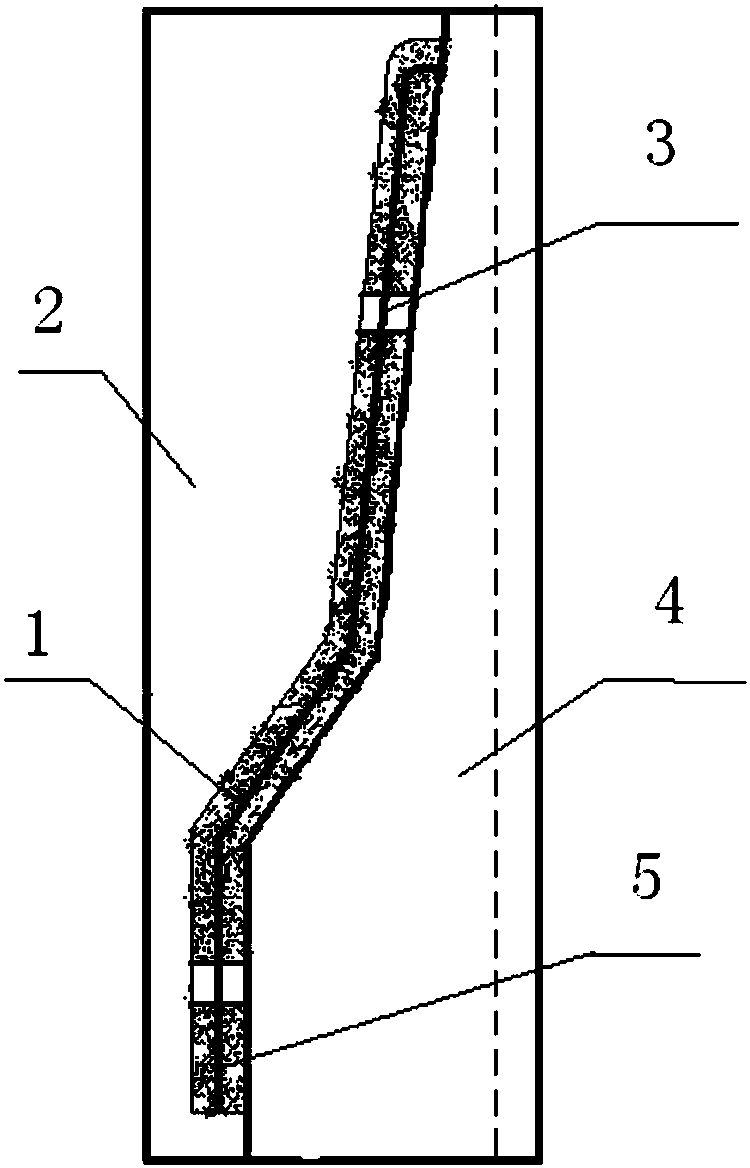

[0085] refer to Figure 1-3 , the present embodiment provides a preparation method of the anti-collision pier using the repaired anti-collision pier guard plate, which includes two parts, namely preparing the anti-collision pier guard plate and installing the anti-collision pier guard plate on the anti-collision pier core body; the steps of preparing the repaired anti-collision pier shield may include the following two types:

[0086] The first method: perfusion method

[0087] S10, apply a release agent on the surface of the outer mold and the core mold that is in contact with the active powder concrete, and close the molds;

[0088] S20, put the material for preparing active powder concrete into a forced mixer, stir to make a uniform slurry, pour it into the mold prepared in step S10, place the anti-collision pier guard plate after the mold loading on the vibrating table, and vibrate Stop when there is no obvious bubble overflow and no bleeding;

[0089] S30, curing the s...

Embodiment 3

[0105] refer to Figure 4-6, this embodiment provides a method for preparing an anti-collision pier using a formwork-type anti-collision pier guard plate, which can be used as a road anti-collision pier and can be moved, but the number is small, and active powder concrete materials need to be used on both sides. Prefabrication in the factory, which includes two major parts, that is, the preparation of the anti-collision pier shield and the formation of the anti-collision pier core inside the anti-collision pier shield; the steps of preparing the formwork type anti-collision pier shield can include the following two types:

[0106] The first method: perfusion method

[0107] S10, apply a release agent on the surface of the outer mold and the core mold that is in contact with the active powder concrete, and close the molds;

[0108] S20, put the material for preparing active powder concrete into a forced mixer, stir to make a uniform slurry, pour it into the mold prepared in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com