A kind of high remanence material and preparation method thereof

A high remanence, alloy material technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problem of low remanence, and achieve the effect of improving remanence, eliminating direct contact and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

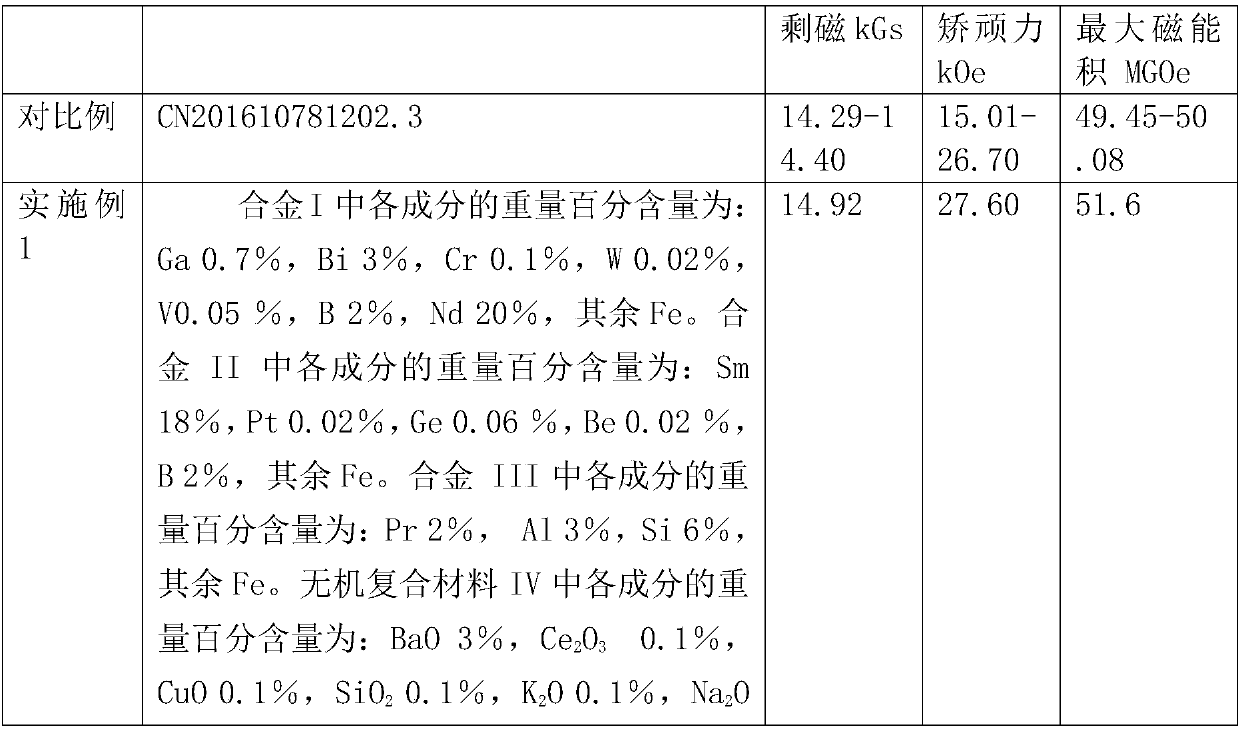

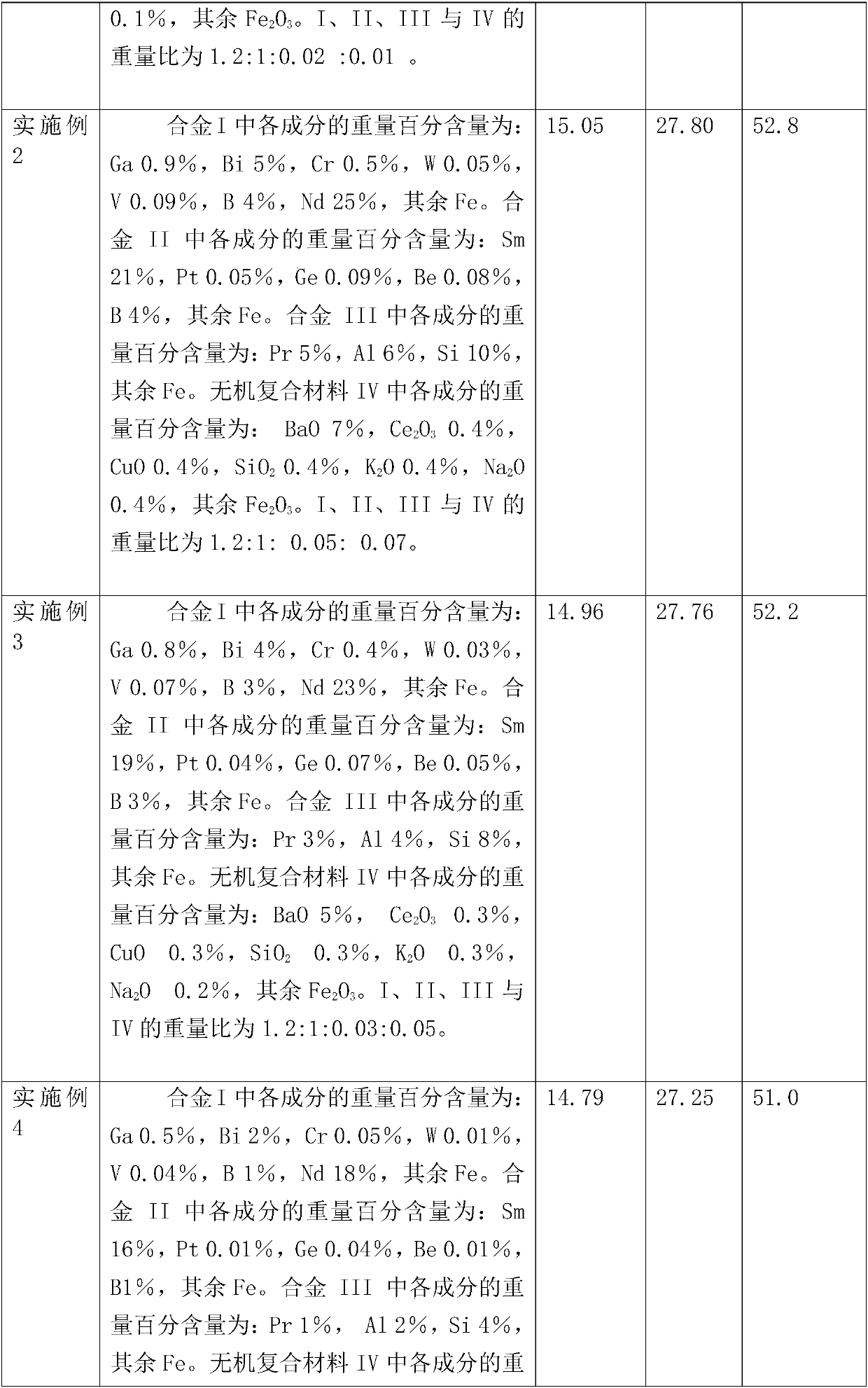

[0028] The present invention will be further described below in conjunction with specific examples.

[0029] A high remanence material, which is composed of three alloy materials I, II, III and an oxide complex IV;

[0030] The weight percentage of each component in the alloy material I is: Ga 0.7-0.9%, Bi 3-5%, Cr 0.1-0.5%, W 0.02-0.05%, V 0.05-0.09%, B 2-4%, Nd 20-25%, the rest Fe;

[0031] The weight percentage of each component in the alloy material II is: Sm 18-21%, Pt 0.02%-0.05%, Ge 0.06%-0.09%, Be 0.02%-0.08%, B 2-4%, and the rest Fe;

[0032] The weight percentage of each component in the alloy material III is: Pr 2-5%, Al 3-6%, Si 6-10%, and the rest Fe;

[0033] The weight percentage of each component in the inorganic composite material IV is: BaO 3-7%, Ce 2 o 3 0.1-0.4%, CuO0.1-0.4%, SiO 2 0.1-0.4%, K 2 O 0.1-0.4%, Na 2 O 0.1-0.4%, the rest Fe 2 o 3 ;

[0034] The weight ratio of the alloy materials I, II, III to the oxide complex IV is 1.2:1:(0.02-0.05):...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com