Methods for selecting film structures for packages

A technology for membrane structure and property selection, applied in the testing of machines/structural components, chemical instruments and methods, applications, etc., can solve problems such as time-consuming, and achieve the effect of improving the drop height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

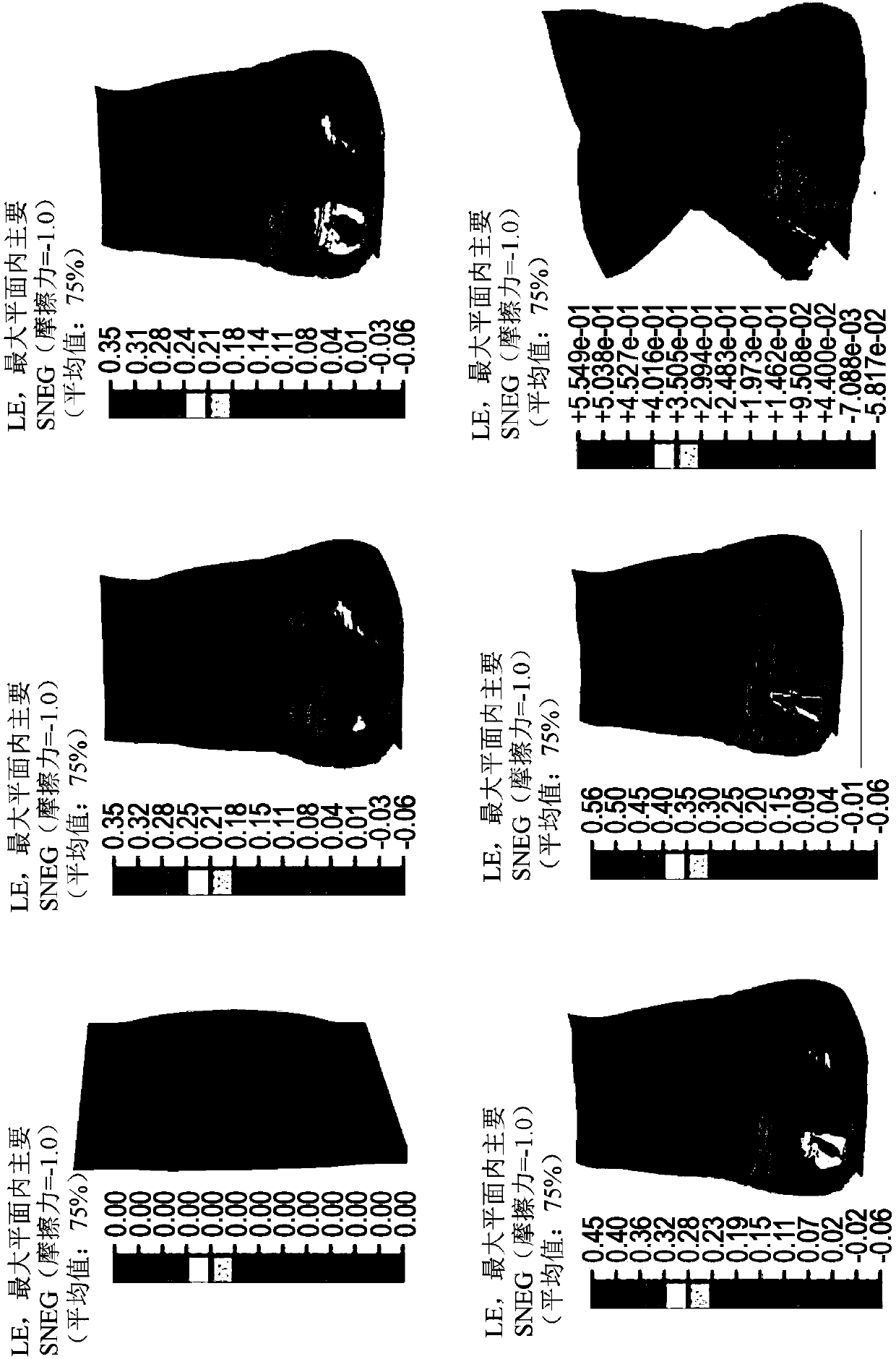

[0033] In this example, FEM analysis was used to simulate how a water-filled bag without a sealed seam would deform and break after impact. figure 1 A series of simulated images showing a bag at different stages of a vertical drop impact. Colors from blue to red in the image indicate increased strain in the laminate.

[0034] An important feature exhibited in the simulated vertical drop impact was the elongation of the laminate in the central lower portion of the bag, which was associated with increased stress concentrations in that region and eventual failure of the laminate due to rupture. This indicates the critical impact direction for this bag.

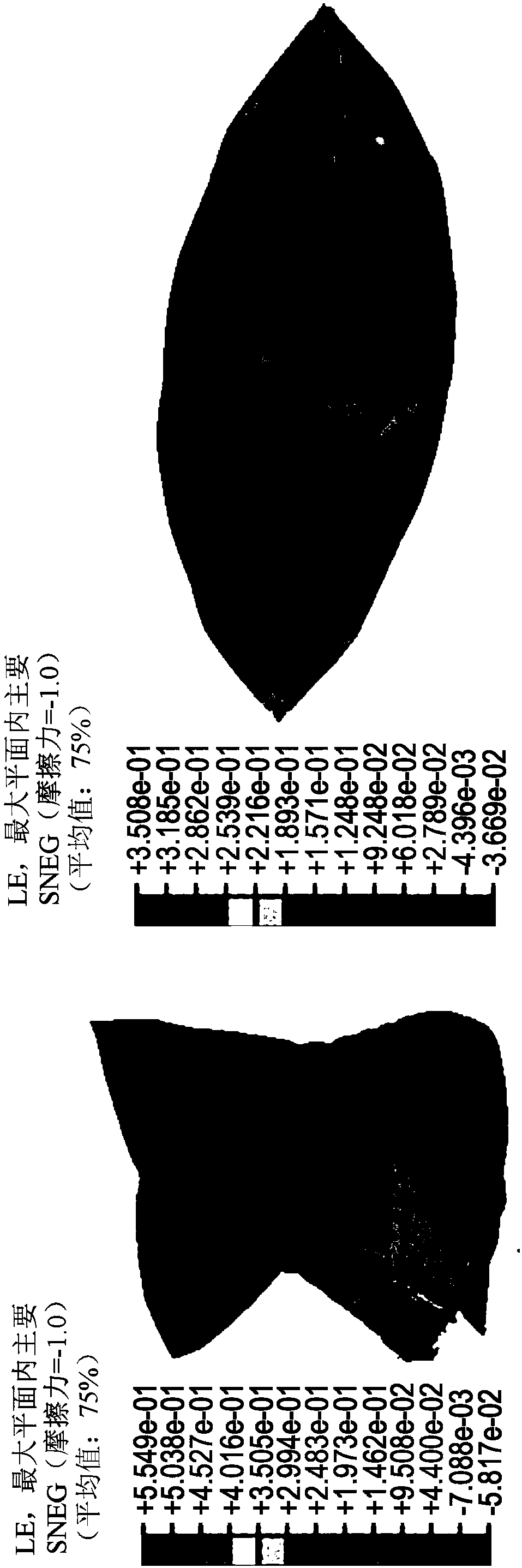

[0035] The critical impact direction chosen in the FEM analysis simulation can play an important role with respect to the fill volume. For example, a bag that is dropped vertically is predicted to break, while a bag that is impacted on a flat larger side is expected not to rip. figure 2 The FEM analysis simulation in , where ...

example 1 and comparative example 1

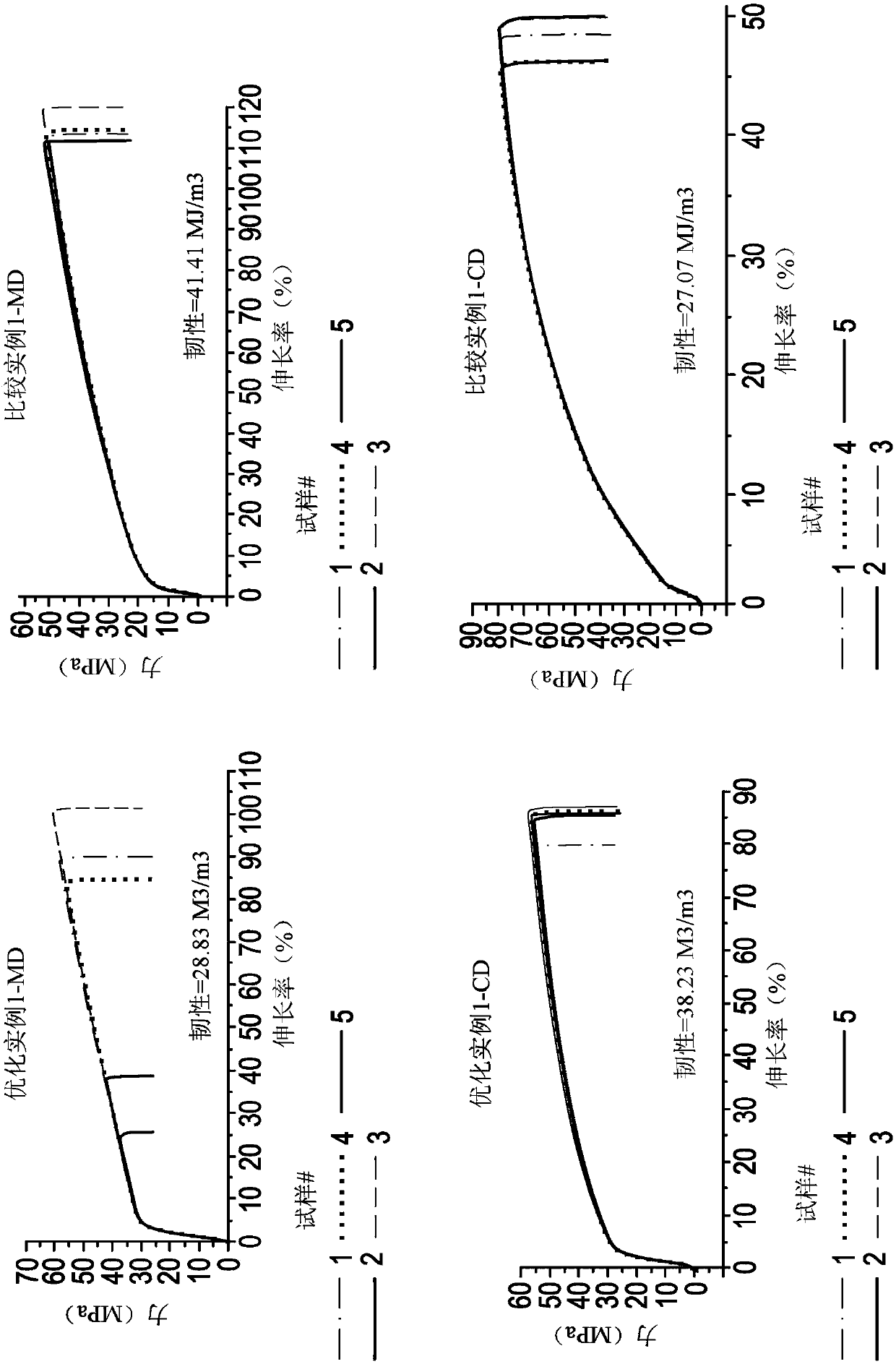

[0037] As demonstrated in the FEM analysis in Example 1, the vertical drop on the bottom seal portion was the most critical for the drop height performance of the pillow bag selected as the sample package for use in the example. considering figure 1 In a set of experiments using laminates with different CD and machine direction (MD) tensile properties, bag deformations observed in FEM simulations of drops, which largely occur in laminates In the cross direction (CD) of , the laminate is formed into bags or bags on a vertical form fill seal machine.

[0038] Two laminates were selected for drop testing. The detailed film structures and compositions of the two laminates are provided in Table 1. Biaxially oriented polypropylene and biaxially oriented PET layers are standard materials available from a variety of sources. ADCOTE TM 675A and 675C are solvent-based polyurethane adhesive systems available from The Dow Chemical Company. DOWLEX TM NG 5056G has 0.919g / cm 3 The den...

example 2 and 3 and comparative example 2 and 3

[0048] Optimized Examples 2 and 3 and Comparative Examples 2 and 3 were prepared according to Table 3. The laminate consisted of a 3-layer co-extruded polyethylene film made on a blown film line using a 200mm die.

[0049] Table 3: Optimizing Examples 2 and 3 and Comparative Examples 2 and 3

[0050]

[0051] Biaxially oriented polyamide and biaxially oriented PET layers are standard materials commercially available from a variety of sources. MORFREE TM 698 and C79 are solvent-free polyurethane adhesive systems available from The Dow Chemical Company. DOWLEX TM NG5056G is a 0.919g / cm 3 The density and the melt index of 1g / 10min (I 2 ) LLDPE resin, which is available from The Dow Chemical Company. AFFINITY TM PF 1140G is with 0.896g / cm3 The density and the melt index of 1.6g / 10min (I 2 ) is a plastomer polyethylene copolymer resin available from The Dow Chemical Company. ELITE TM 5960G is with 0.960g / cm 3 The density and the melt index of 0.85g / 10min (I 2 ) is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com