Seawater high-quality pelagic egg sieving and separating method, adopted separation barrel and use method of separation barrel

A separation method and technology for separation barrels are applied in the field of separation barrels, seawater floating fish eggs screening and separation, which can solve the problems of rough and uneven inner walls of the barrels, scratched fish eggs, affecting the hatching of fish eggs and seedling cultivation, etc., and achieve transparency. Good, reduce damage, improve the effect of hatching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For the convenience of those skilled in the art to understand, the present invention will be described in further detail below in conjunction with the drawings and specific embodiments.

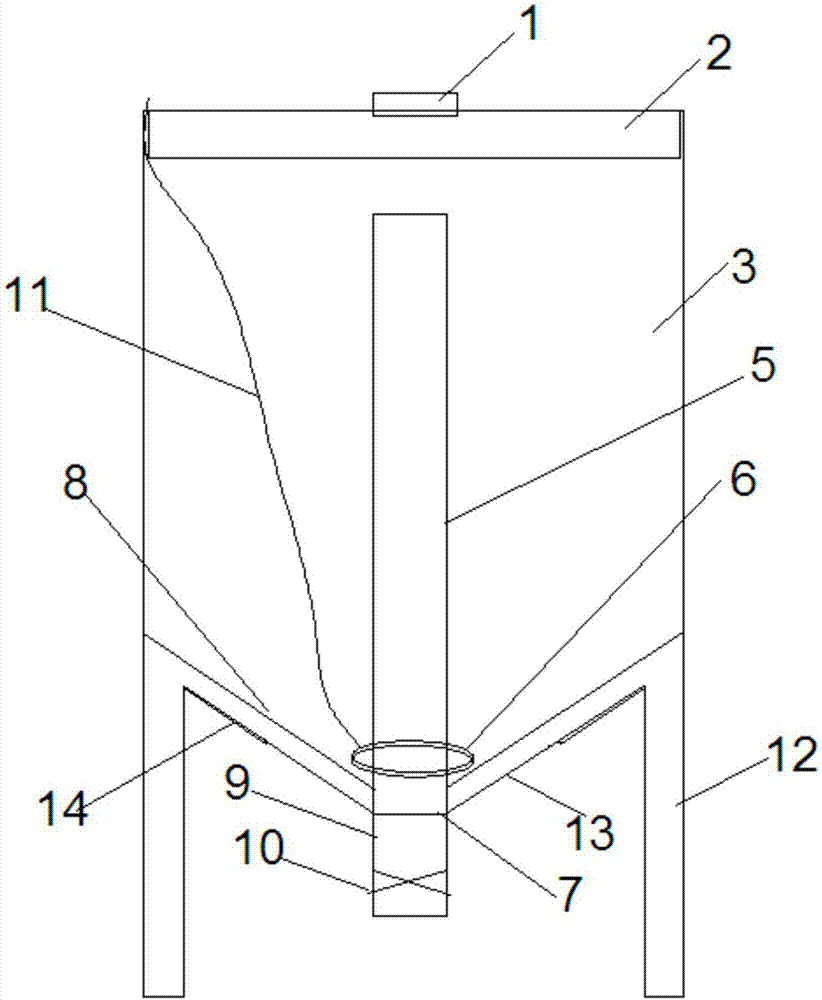

[0034] Such as Figure 1~2 As shown, the separation bucket for seawater floating fish roe screening in this embodiment includes a separation bucket main body 3 equipped with a bucket cover 2, and a handle 1 is provided on the bucket cover 2.

[0035] The bung 2 is black and opaque, and the inner surface is provided with an annular inlay plate equivalent to the inner diameter of the separation barrel main body 3 to block light from entering.

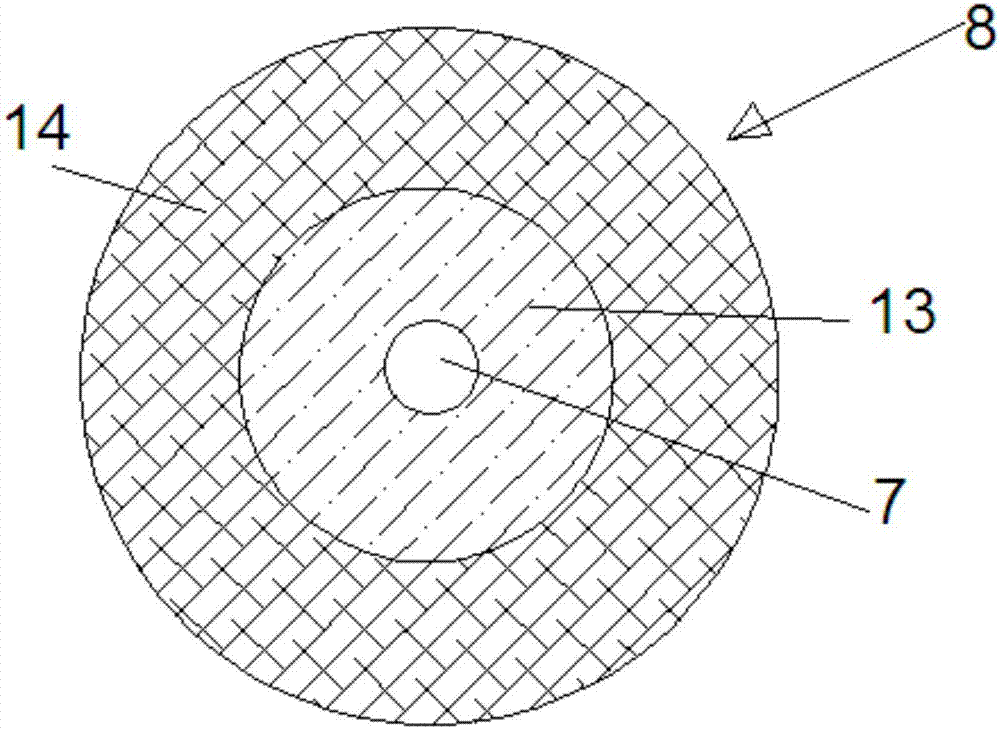

[0036] The main body 3 of the separation barrel is made of acrylic, cylindrical, and the outer wall is black, such as coating with a light-shielding coating. The bottom 8 of the barrel is funnel-shaped, and a circular transparent circle 13 with a certain diameter is arranged around the water outlet 7 to form a light-transmitting area. Other areas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com