Metal powder preparation method and device based on thermal spraying

A metal powder, thermal spraying technology, applied in the field of powder metallurgy, can solve problems such as low efficiency, achieve the effect of improving efficiency, solving efficiency problems, and being conducive to the refinement of droplet size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

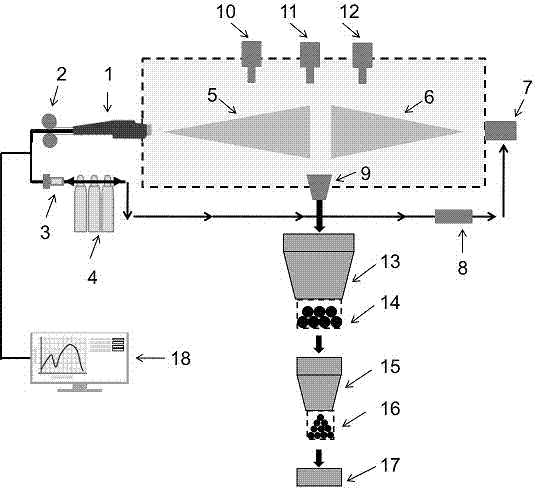

[0036] Prepare metal aluminum, the device is as attached figure 1 shown. The raw material is cast metal aluminum wire with a diameter of 4.0 mm.

[0037] The wire feed rate of the thermal spray generator is 15g / min, the flow rate of argon gas is 150L / min, the flow rate of nitrogen gas is 12L / min, the current is 350A, the voltage is 65V, and the spray distance is 120mm. The cooling gas is compressed argon with a velocity of 300m / s. The size of the cooling beam is equivalent to the size of the metal droplet beam.

[0038] The size of the primary cooling sieve is 60-120 microns; the sieve size of the secondary filter is 20-60 microns;

Embodiment 2

[0040] Preparation of metal copper, the device is as attached figure 1 shown. The raw material is cast copper wire with a diameter of 3.6 mm.

[0041] The wire feed rate of the thermal spray generator is 16g / min, the flow rate of argon gas is 180L / min, the flow rate of nitrogen gas is 14L / min, the current is 420A, the voltage is 72V, and the spray distance is 180mm. The cooling gas is compressed argon with a velocity of 250m / s. The size of the cooling beam is equivalent to the size of the metal droplet beam.

[0042] The size of the primary cooling sieve is 80-160 microns; the sieve size of the secondary filter is 30-80 microns;

Embodiment 3

[0044] Preparation of metal copper-tin alloy, the device is as attached figure 1 shown. The raw material is copper-tin wire with a diameter of 5.0mm in cast state.

[0045]The wire feed rate of the thermal spray generator is 15g / min, the flow rate of argon gas is 150L / min, the flow rate of nitrogen gas is 12L / min, the current is 350A, the voltage is 650V, and the spray distance is 80-500mm. The cooling gas is compressed argon with a velocity of 300m / s. The size of the cooling beam is equivalent to the size of the metal droplet beam.

[0046] The size of the primary cooling sieve is 60-120 microns; the sieve size of the secondary filter is 20-60 microns;

[0047] It can be seen from the above-mentioned embodiments that the fat powder process based on the thermal spraying generating device to generate metal droplet beams and compressed gas beams for front cooling, saves the crucible smelting in the prior art, and greatly improves the production efficiency while realizing cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com