Production line for steel wire glass fiber reinforced composite pipe

A technology for enhancing compounding and production lines, applied in the direction of tubular items, household appliances, other household appliances, etc., can solve the problems of inability to make production lines, achieve a high degree of automation, reduce heat waste, and facilitate centralized heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific examples.

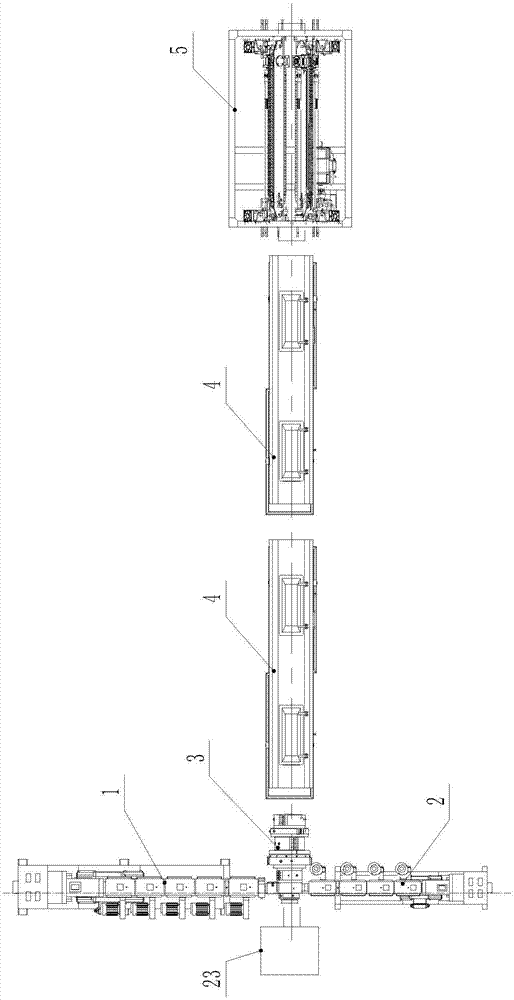

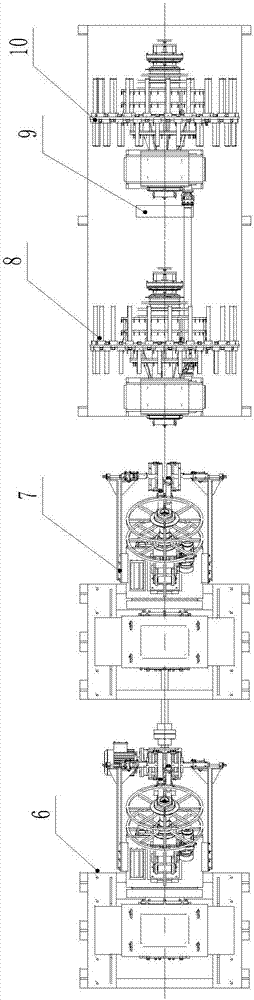

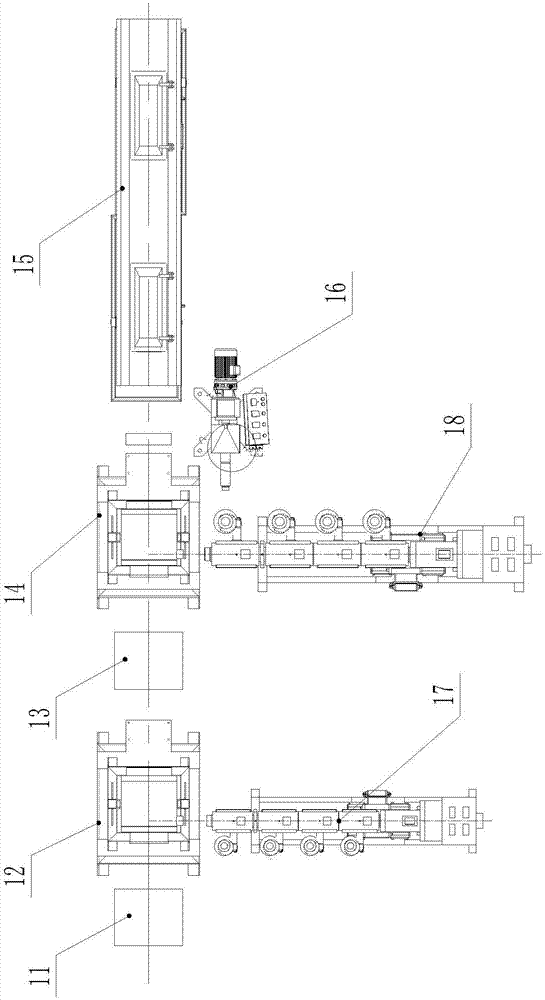

[0030] Such as Figure 1 to Figure 5 As shown, the production line of the steel wire glass fiber reinforced composite pipe includes an inner pipe extruder for extruding an inner pipe, the inner pipe extruder includes an extruder body 1 and an inner pipe die 3, and the extruder The discharge machine body 1 is arranged on one side of the inner pipe die 3 and communicates with the inner pipe die 3 , and the upstream end of the inner pipe die 3 is provided with an air vent communicating with the inner hole of the inner pipe. Such as figure 1 As shown, the production line also includes a functional layer extruder 2 for forming a functional layer inside the inner tube, the functional layer extruder 2 is connected to the inner tube die 3 and is located on the other side of the inner tube die 3 . The arrangement direction of the extruder body 1 of the inner tube extruder is perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com